Lynn Robinson. Showman Scenic

+36

martinj

prince of wales

gwr1475

burrell1

ejparrott

iain

Adam Brown

tractor mike

northburrell

Tassie Tiger

atomenter

Richard

Tim Pennett

Flasback

MrStationHouse

mikero

chop

Dan

IanL

Kevster

Steam Traction World

Tim Watson

Robfishman

Brian M

sonick45

tef 20

greystones

Graeme81

bjwlancashire

Tony King

Steve Traill

Rickster

Vapor

highpressure

craig@STW

lynnr

40 posters

Page 22 of 40

Page 22 of 40 •  1 ... 12 ... 21, 22, 23 ... 31 ... 40

1 ... 12 ... 21, 22, 23 ... 31 ... 40

Life and Everything

Life and Everything

Hi All

Sorry for the sporadic updates of late. There is an old Chinese proverb "May you live in interesting times". Well I think it is more of a curse.

Due to a number of family crisis's, between mother being in hospital with pneumonia, father having cancer cut of his face and myself loosing one of my dogs. But thing are getting better again.

As you have seen Crystal was in steam last Monday and actually ran for the first time. She ran sweet. Bit stiff and hot for the first minute or so but after a fresh oil round and a bit extra down the sides of the big ends etc she eased off and ran for about 5 hours.

Safety valves POPPED open bang on 180psi and snapped shut at 175psi.

Steam injector worked a charm all the way from 50psi right up to 180psi. Good rate of injection and not too hungry on steam.

Starting valve sealed up very well once pressure passed 100psi then kept shut without leaking for the rest of the day with no problem. Never needed to use the valve as the rod is currently disconnected. If the engine would not turn over in forward. A quick flick in to reverse got her going and back in to forward. Valve also stayed shut an leak free right down to 0psi (relative)

Clack valves both worked well after a second "tap" with a hammer to seat the balls. No back leaks at all.

Cylinder block has settled well and is not leaking from any studs or the gasket. Once small leak from one of the "core" drilling holes on the front of the block. Possibly I forgot to seal the threads of the grub screw.

Whistle. Most of the time it stayed sealed but once in a while would not shut off and leaked a bit. So it will be coming apart again as the seat had not been tapped by the hammer yet. So no surprise it is temperamental.

Piston and valve covers and glands are all tight. No steam leaks or squeaks. I will be taking the valve covers off for an inspection at some point before the next steaming.

Weigh-shaft alignment is very good as there is no knocking or tightness associated with the cross-heads. Only had a small squeak. Which I think is the little end needing some oil added.

Mechanical lubricator. Worked like a charm. Rotating nicely via the one way clutches without sticking.

Only other issue at the moment is the blast tube joint is not sealed fully so letting out onto the top of the smokebox and cleading.

All in all a very successful test steaming. Paul Garfield from Rugby area visited to see the engine running which was good.

P.S. The handle on the smokebox broke when I tried to open the door to clean out. The silver solder was only about 1mm as the shaft was not fitted down into the hole at all. Cleaned up the handle shaft, drilled out the hole. I then loose tapped threads on the 2 parts. Screwed together then silver soldered the joint. STAY!

Not bad for 2 years to the day from the start of this project.

Sorry for the sporadic updates of late. There is an old Chinese proverb "May you live in interesting times". Well I think it is more of a curse.

Due to a number of family crisis's, between mother being in hospital with pneumonia, father having cancer cut of his face and myself loosing one of my dogs. But thing are getting better again.

As you have seen Crystal was in steam last Monday and actually ran for the first time. She ran sweet. Bit stiff and hot for the first minute or so but after a fresh oil round and a bit extra down the sides of the big ends etc she eased off and ran for about 5 hours.

Safety valves POPPED open bang on 180psi and snapped shut at 175psi.

Steam injector worked a charm all the way from 50psi right up to 180psi. Good rate of injection and not too hungry on steam.

Starting valve sealed up very well once pressure passed 100psi then kept shut without leaking for the rest of the day with no problem. Never needed to use the valve as the rod is currently disconnected. If the engine would not turn over in forward. A quick flick in to reverse got her going and back in to forward. Valve also stayed shut an leak free right down to 0psi (relative)

Clack valves both worked well after a second "tap" with a hammer to seat the balls. No back leaks at all.

Cylinder block has settled well and is not leaking from any studs or the gasket. Once small leak from one of the "core" drilling holes on the front of the block. Possibly I forgot to seal the threads of the grub screw.

Whistle. Most of the time it stayed sealed but once in a while would not shut off and leaked a bit. So it will be coming apart again as the seat had not been tapped by the hammer yet. So no surprise it is temperamental.

Piston and valve covers and glands are all tight. No steam leaks or squeaks. I will be taking the valve covers off for an inspection at some point before the next steaming.

Weigh-shaft alignment is very good as there is no knocking or tightness associated with the cross-heads. Only had a small squeak. Which I think is the little end needing some oil added.

Mechanical lubricator. Worked like a charm. Rotating nicely via the one way clutches without sticking.

Only other issue at the moment is the blast tube joint is not sealed fully so letting out onto the top of the smokebox and cleading.

All in all a very successful test steaming. Paul Garfield from Rugby area visited to see the engine running which was good.

P.S. The handle on the smokebox broke when I tried to open the door to clean out. The silver solder was only about 1mm as the shaft was not fitted down into the hole at all. Cleaned up the handle shaft, drilled out the hole. I then loose tapped threads on the 2 parts. Screwed together then silver soldered the joint. STAY!

Not bad for 2 years to the day from the start of this project.

Last edited by lynnr on Wed 22 Aug 2012, 2:31 pm; edited 2 times in total (Reason for editing : Added a bit)

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Lynn Robinson. Showman Scenic

Re: Lynn Robinson. Showman Scenic

It looks great, and I'm pleased everything is working out ok with the family and they are getting better. From what I read the flywheel will be flying it's way to your door shortly.

BS42802 Blast pipe

BS42802 Blast pipe

Hi All

Be careful if you need to remove the elbow on the blast pipe. Mine was very stiff and as I was trying to unwind it the threads on the brass blast pipe sheared. Very thin walls under the threaded section.

Be careful if you need to remove the elbow on the blast pipe. Mine was very stiff and as I was trying to unwind it the threads on the brass blast pipe sheared. Very thin walls under the threaded section.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Lynn Robinson. Showman Scenic

Re: Lynn Robinson. Showman Scenic

engine looks and sounds wonderful lynn, well done

Graeme81- Number of posts : 178

Location : Ireland

Registration date : 2009-05-25

Re: Lynn Robinson. Showman Scenic

Re: Lynn Robinson. Showman Scenic

Whoot

Kit has arrived

Kit has arrived

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Lynn Robinson. Showman Scenic

Re: Lynn Robinson. Showman Scenic

Alas, mine has not  & I don't think there'll be a delivery on monday!!

& I don't think there'll be a delivery on monday!!

Tony King- Number of posts : 856

Age : 69

Location : scotland

Registration date : 2008-10-31

Re: Lynn Robinson. Showman Scenic

Re: Lynn Robinson. Showman Scenic

Just to let you know that the instructions say to butt the flywheel up to the drive cog for the water pump but if you do this it is likely you will scrape the paint off one of the rivets on the gear guard. I have got Andy2 to make up a spacer 8mm in width to allow the flywheel to butt right up tight against it. This works fine and looks good too.

Now trying to work out which bits need to be plated or painted or what before I tackle this one. Hoping to actually run for some distance this weekend as I now have the collar for the RH wheel.

Now trying to work out which bits need to be plated or painted or what before I tackle this one. Hoping to actually run for some distance this weekend as I now have the collar for the RH wheel.

Productive

Productive

Hi All

Just a short update.

Me been in the engine shed!

Flywheel fitted.

I ground most of the rivet down and then added a 3mm home made brass washer to allow the flywheel to run free and be up against the bearing bunch.

Not much space but enough.

As Craig said. Getting very tight in there.

Inside of the flywheel

And yes it does ring like a bell. Hit it by mistake with the hammer and it resonated for about 2 minutes.

Then I moved on to the gear change, after working on the right hand drive flange keys. But forgot to take a picture of that as it is in the paint shop.

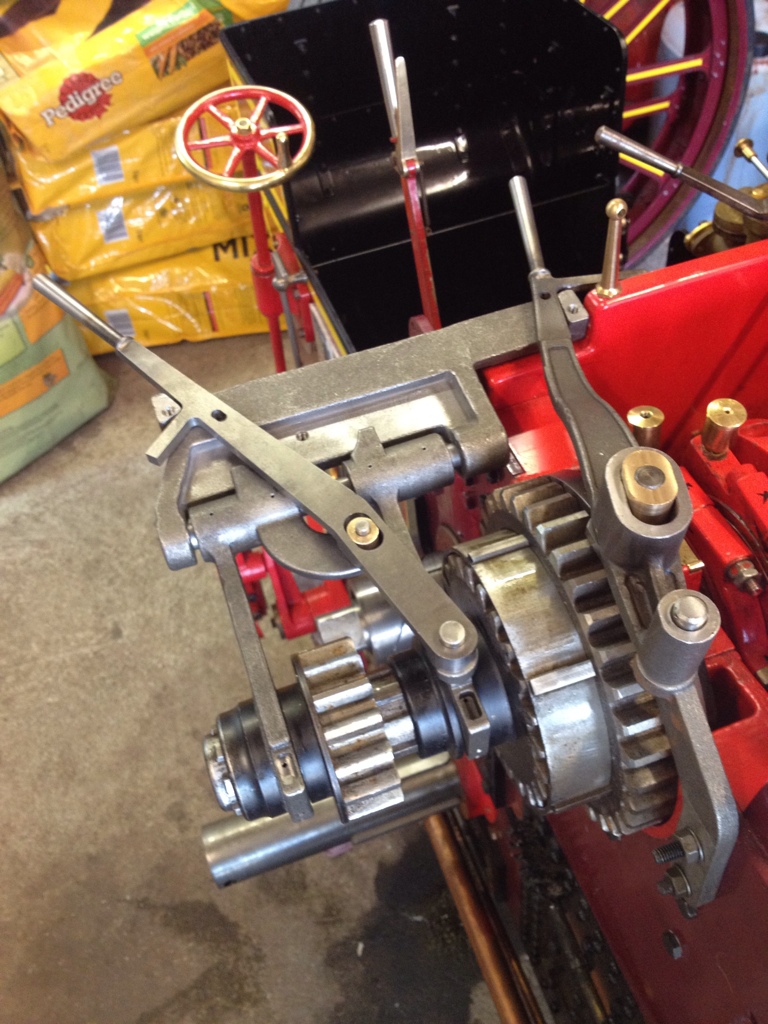

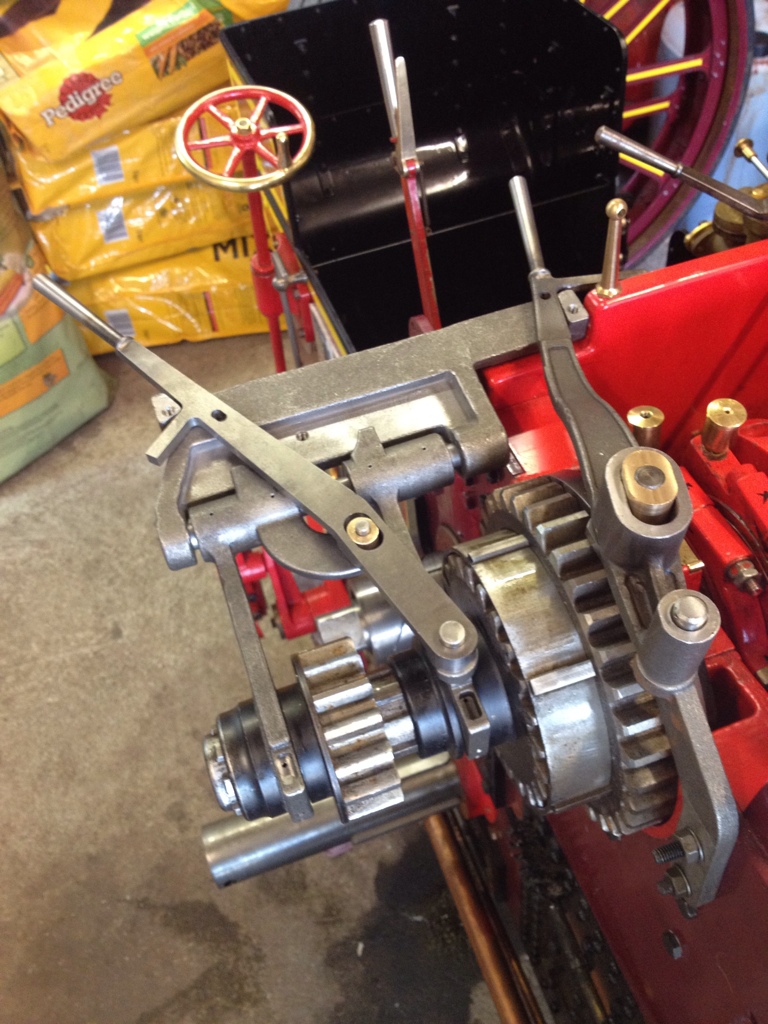

Ok Gear change

Gear change fitted. Couple of issues

Couple of issues.

Not sure if second gear is far enough in to the boss as the lockout butterfly does not fit to the 2nd gear by about 5mm

The key ways on the 3rd gear need rounding off as they do not allow the gear to move into mesh but easily out.

Locking pin plate does not actual reach between the mounting bolt holes and there should be 2 x M5 bolts but these are not in the kit and not shown on the packing list either but mentioned in the instructions.

I need to dismount the 1st gear again to re-install the 2nd shaft gear pack to see if it help in aligning 2nd.

Just a short update.

Me been in the engine shed!

Flywheel fitted.

I ground most of the rivet down and then added a 3mm home made brass washer to allow the flywheel to run free and be up against the bearing bunch.

Not much space but enough.

As Craig said. Getting very tight in there.

Inside of the flywheel

And yes it does ring like a bell. Hit it by mistake with the hammer and it resonated for about 2 minutes.

Then I moved on to the gear change, after working on the right hand drive flange keys. But forgot to take a picture of that as it is in the paint shop.

Ok Gear change

Gear change fitted. Couple of issues

Couple of issues.

Not sure if second gear is far enough in to the boss as the lockout butterfly does not fit to the 2nd gear by about 5mm

The key ways on the 3rd gear need rounding off as they do not allow the gear to move into mesh but easily out.

Locking pin plate does not actual reach between the mounting bolt holes and there should be 2 x M5 bolts but these are not in the kit and not shown on the packing list either but mentioned in the instructions.

I need to dismount the 1st gear again to re-install the 2nd shaft gear pack to see if it help in aligning 2nd.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Lynn Robinson. Showman Scenic

Re: Lynn Robinson. Showman Scenic

Lynn,

Looking good, that is very tight on the flywheel brake rod, is there enough clearance ?

Ian

Looking good, that is very tight on the flywheel brake rod, is there enough clearance ?

Ian

IanL- Number of posts : 437

Age : 69

Location : Nottinghamshire

Registration date : 2011-07-25

Re: Lynn Robinson. Showman Scenic

Re: Lynn Robinson. Showman Scenic

IanL wrote:Lynn,

Looking good, that is very tight on the flywheel brake rod, is there enough clearance ?

Ian

Nats hair width but ok. Nothing is really going to move.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Lynn Robinson. Showman Scenic

Re: Lynn Robinson. Showman Scenic

Nice pictures Lynn, glad to see you back in full flow!!

Regards,

Tony

Regards,

Tony

Tony King- Number of posts : 856

Age : 69

Location : scotland

Registration date : 2008-10-31

Re: Lynn Robinson. Showman Scenic

Re: Lynn Robinson. Showman Scenic

Spot the problem

The ring is a dry fit and fell off when I first tried to come out of gear.

The ring is a dry fit and fell off when I first tried to come out of gear.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Lynn Robinson. Showman Scenic

Re: Lynn Robinson. Showman Scenic

Got 3rd gear sorted

Heated ring and refitted. Them pot drilled and welded on.

Not overly prity but it will do

Heated ring and refitted. Them pot drilled and welded on.

Not overly prity but it will do

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Lynn Robinson. Showman Scenic

Re: Lynn Robinson. Showman Scenic

Hi Lynn,

I had exactly the same problem with my third gear outer ring.

Having it spot wielded in the week.

Cheers,

Brian

I had exactly the same problem with my third gear outer ring.

Having it spot wielded in the week.

Cheers,

Brian

Brian M- Number of posts : 261

Location : Cheshire

Registration date : 2011-01-30

Re: Lynn Robinson. Showman Scenic

Re: Lynn Robinson. Showman Scenic

More done. I had to remove a 1mm washer from the diff to get the wheel locking collers to fit.

Not sue what the time would be for getting the gear shift plate re-fabricated or just weld up the 2 holes and move them myself. Would take. 10 minutes or so.

Overall view of the motion.

Not sue what the time would be for getting the gear shift plate re-fabricated or just weld up the 2 holes and move them myself. Would take. 10 minutes or so.

Overall view of the motion.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Lynn Robinson. Showman Scenic

Re: Lynn Robinson. Showman Scenic

For those who want to line out their gear guard. The gard is not covered at all by the gear change.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Lynn Robinson. Showman Scenic

Re: Lynn Robinson. Showman Scenic

Just a little video of Crystal chugging away.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Lynn Robinson. Showman Scenic

Re: Lynn Robinson. Showman Scenic

What a lovely sight Lynn, that flywheel sure makes it run nice & smooth. You must be really chuffed!!

Regards,

Tony

Regards,

Tony

Tony King- Number of posts : 856

Age : 69

Location : scotland

Registration date : 2008-10-31

Re: Lynn Robinson. Showman Scenic

Re: Lynn Robinson. Showman Scenic

looking great..where did u get the chimney extension?

Graeme81- Number of posts : 178

Location : Ireland

Registration date : 2009-05-25

Re: Lynn Robinson. Showman Scenic

Re: Lynn Robinson. Showman Scenic

Thanks tony and Graeme .

The extension is a old piece of Tin plate originally used in a can factory for making lids out if. Just rolled up and some masking tape to hold. Does the job. Think we get an extension in the kit at some point.

The extension is a old piece of Tin plate originally used in a can factory for making lids out if. Just rolled up and some masking tape to hold. Does the job. Think we get an extension in the kit at some point.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Lynn Robinson. Showman Scenic

Re: Lynn Robinson. Showman Scenic

have u driven her around much?

Graeme81- Number of posts : 178

Location : Ireland

Registration date : 2009-05-25

Re: Lynn Robinson. Showman Scenic

Re: Lynn Robinson. Showman Scenic

No driving yet. No space. So I need to wait until she has her ticket.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Lynn Robinson Showmans Scenic

Lynn Robinson Showmans Scenic

Hi Lynn

You have done a wonderful job and must be pleased with how smooth she runs. Excellent work!!

Phil

You have done a wonderful job and must be pleased with how smooth she runs. Excellent work!!

Phil

Tassie Tiger- Number of posts : 47

Age : 60

Location : Tasmania Australia

Registration date : 2012-01-01

Re: Lynn Robinson. Showman Scenic

Re: Lynn Robinson. Showman Scenic

Hi

Yes I am very pleased indeed. Had an issue on Saturday where the engine would not stop when the regulator was closed. Think it is the start button. Which held steam tight the last time she ran, but not this time. So I cut short the steaming. Then during the cool down and tidy up it started raining. The rain passed and I dropped the remains of the fire out, mostly ash by this time and guess what! Just as the pan it the ground a gust of wind came up from no where and the fly ash went flying!!!! Over me, over Crystal and every where in the garage. I was on fire watch for 1 hour after that. Luckily no problems.

I was going to move the fence out of the way and run the engine back and forward between the back of the garage and the the top edge of the drive. Giving me a run of 35ft. Whoo. But not with a engine that would not stop!

All leaks now fixed so she is about ready for testing once the blanking plates arrive (next kit I hope). No real rush now for testing as the rally season is almost over. Got 2 events but they will not be steaming events.

Will be steaming the engine through out the winter. I must remember to get a couple of heater belts to try as frost guards.

Yes I am very pleased indeed. Had an issue on Saturday where the engine would not stop when the regulator was closed. Think it is the start button. Which held steam tight the last time she ran, but not this time. So I cut short the steaming. Then during the cool down and tidy up it started raining. The rain passed and I dropped the remains of the fire out, mostly ash by this time and guess what! Just as the pan it the ground a gust of wind came up from no where and the fly ash went flying!!!! Over me, over Crystal and every where in the garage. I was on fire watch for 1 hour after that. Luckily no problems.

I was going to move the fence out of the way and run the engine back and forward between the back of the garage and the the top edge of the drive. Giving me a run of 35ft. Whoo. But not with a engine that would not stop!

All leaks now fixed so she is about ready for testing once the blanking plates arrive (next kit I hope). No real rush now for testing as the rally season is almost over. Got 2 events but they will not be steaming events.

Will be steaming the engine through out the winter. I must remember to get a couple of heater belts to try as frost guards.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Lynn Robinson. Showman Scenic

Re: Lynn Robinson. Showman Scenic

How many times are these engines actually been rebuilt???

Parts off again for painting and fettling.

Wheels off again.

Stripping down the gear assemblies

Flywheel off for painting

More parts coming off.

Removing the stearing shaft helpes for space getting the brake bracket off.

Flywheel got it paint on. I will see how it looks before thinking about another coat.

3rd gear drive boss modification performed.

And

Waterpump removed for returning to base.

Parts off again for painting and fettling.

Wheels off again.

Stripping down the gear assemblies

Flywheel off for painting

More parts coming off.

Removing the stearing shaft helpes for space getting the brake bracket off.

Flywheel got it paint on. I will see how it looks before thinking about another coat.

3rd gear drive boss modification performed.

And

Waterpump removed for returning to base.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Page 22 of 40 •  1 ... 12 ... 21, 22, 23 ... 31 ... 40

1 ... 12 ... 21, 22, 23 ... 31 ... 40

Similar topics

Similar topics» Lynn Robinson. Showman Scenic

» Lynn Robinson. Showman Scenic Part 2

» The Engine Shed. Photo gallery.

» Lynn Robinson 4" water bowser

» Lynn Robinson. 4" traction Wagon. Twins. "Mara" and "Uisge"

» Lynn Robinson. Showman Scenic Part 2

» The Engine Shed. Photo gallery.

» Lynn Robinson 4" water bowser

» Lynn Robinson. 4" traction Wagon. Twins. "Mara" and "Uisge"

Page 22 of 40

Permissions in this forum:

You cannot reply to topics in this forum