Road Loco - 'Blackbeard'

+25

MrStationHouse

richspoo

mikero

Steam Traction World

ejparrott

the coleman

iain

IanL

Robfishman

northburrell

Flasback

craig@STW

Graeme81

highpressure

Tim Watson

Brian M

Rickster

LilyJack

Steve Traill

hughb

sonick45

Kevster

lynnr

Tony King

bjwlancashire

29 posters

Page 5 of 17

Page 5 of 17 •  1, 2, 3, 4, 5, 6 ... 11 ... 17

1, 2, 3, 4, 5, 6 ... 11 ... 17

Re: Road Loco - 'Blackbeard'

Re: Road Loco - 'Blackbeard'

Awe. Cutie.

Think min age is 7.

Noticed from the first picture. Interesting hatch in the back wall. Previous owners used the garage for a dog house?

Think min age is 7.

Noticed from the first picture. Interesting hatch in the back wall. Previous owners used the garage for a dog house?

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Road Loco - 'Blackbeard'

Re: Road Loco - 'Blackbeard'

Like the new workshop, very nice. Sounds like you will be pleased to get back to work on the build.

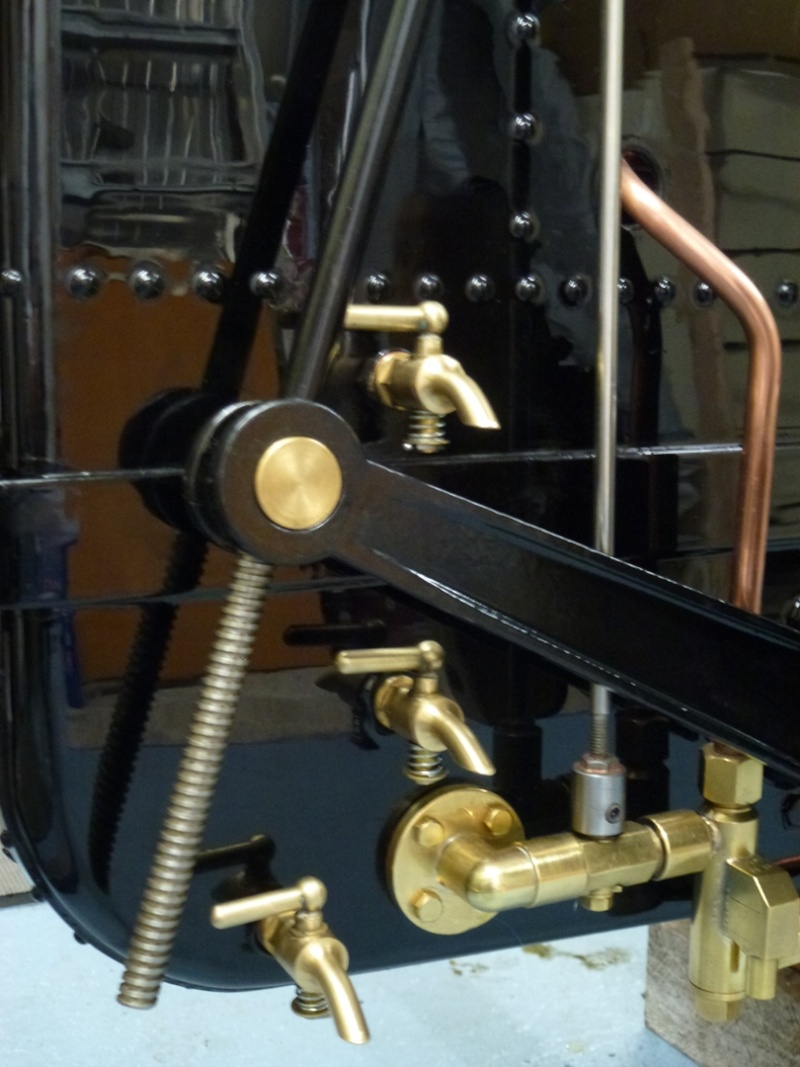

Some detail updates

Some detail updates

I have been a little slack lately in putting updates on my build thread since the house move so I though I would pass a but of time in the evening while in Germany again.

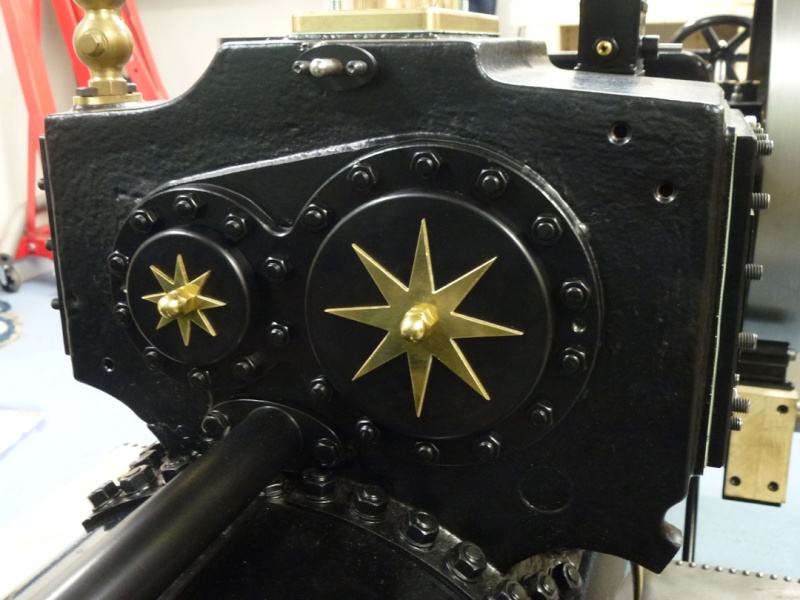

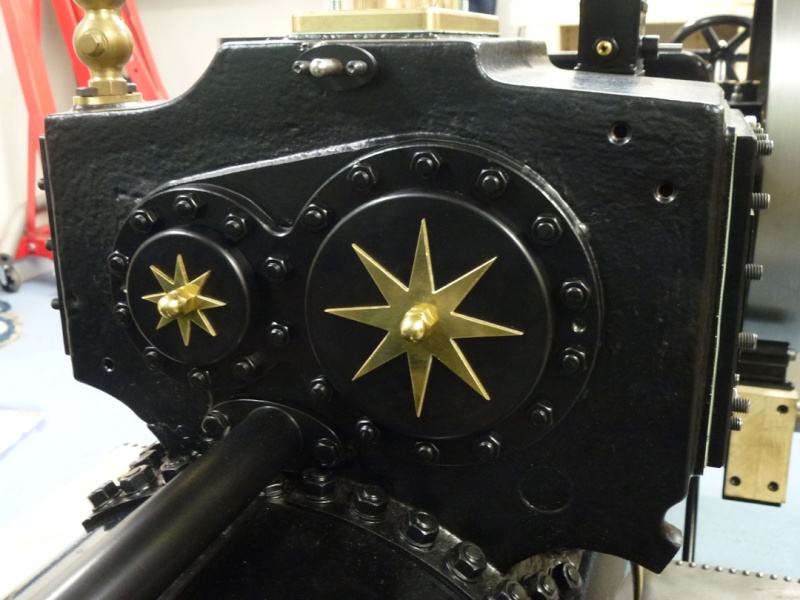

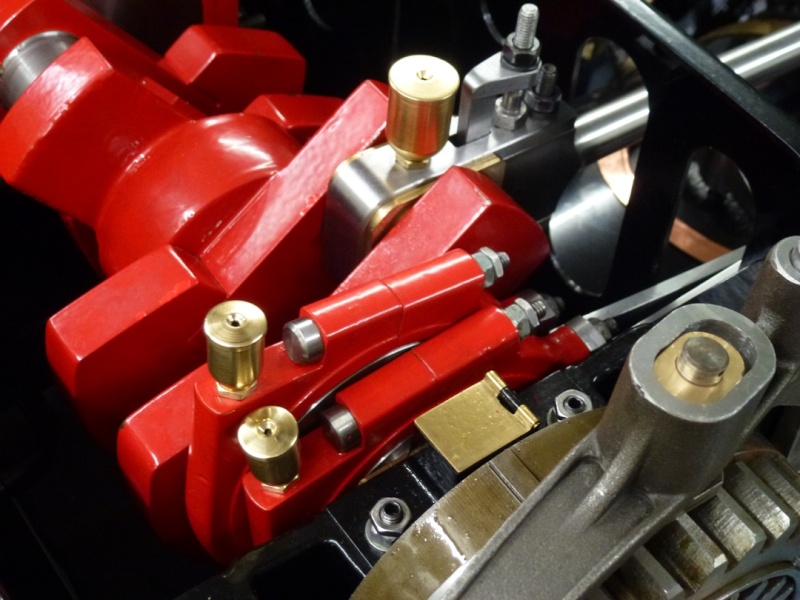

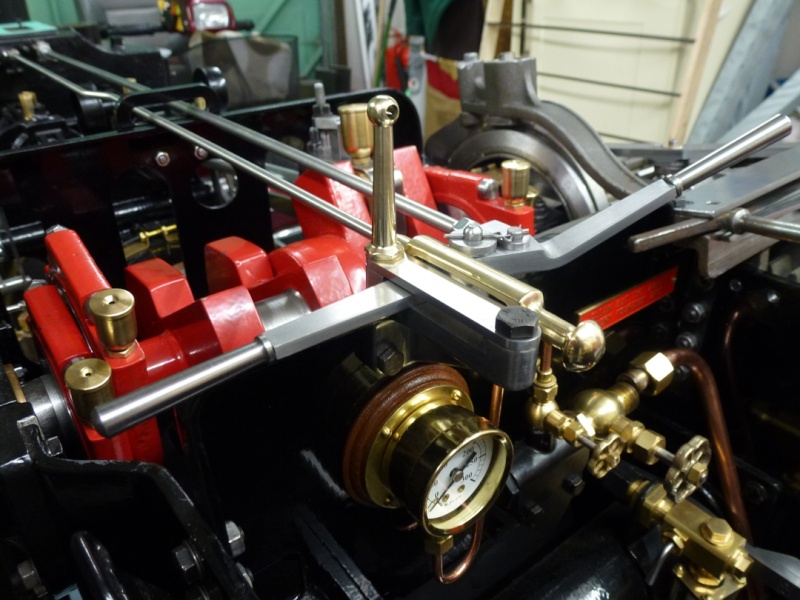

Finished cylinder end cover detail, I will also be painting the nuts on the valve chest covers once the valves are set and covers finally fitted. I did buy some dome nuts for the covers but once I put them on I did not like the look with all the black around them.

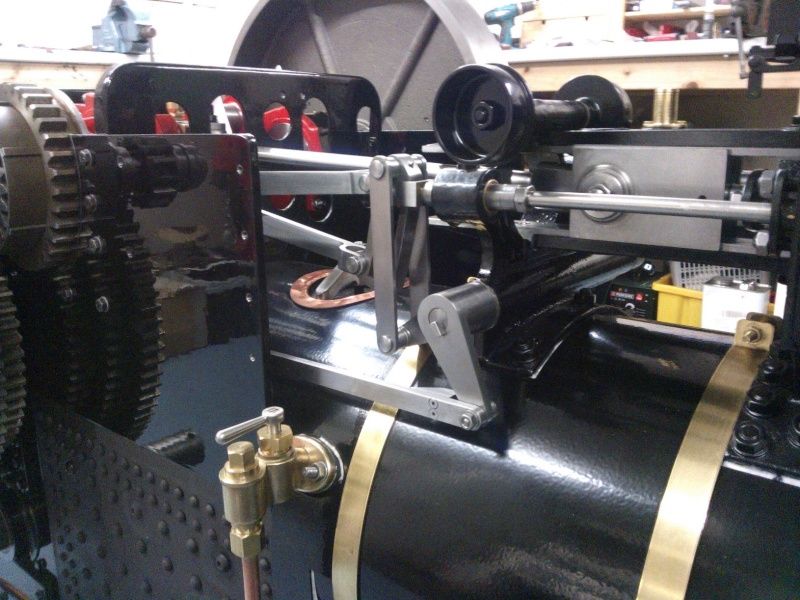

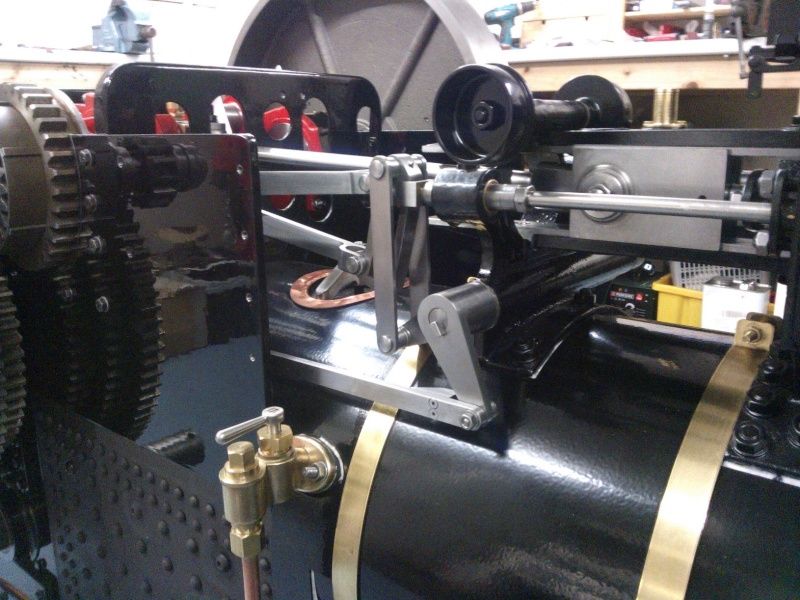

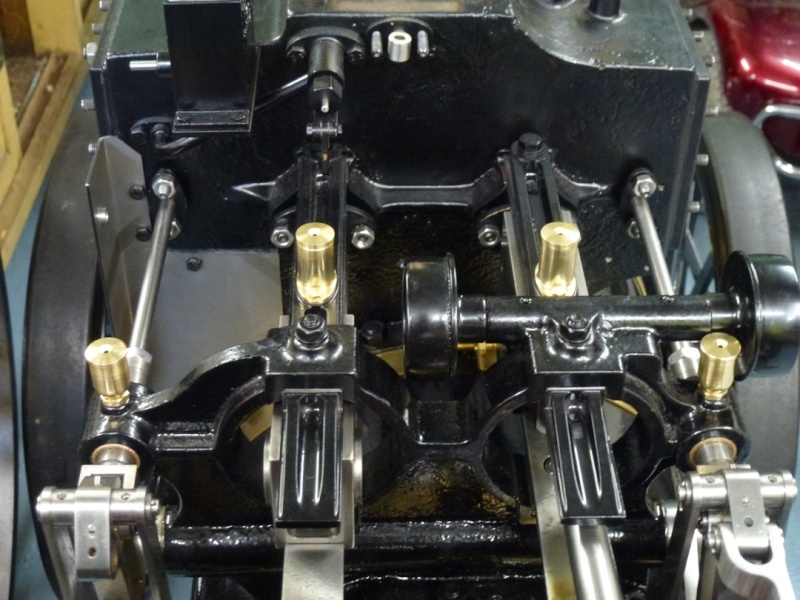

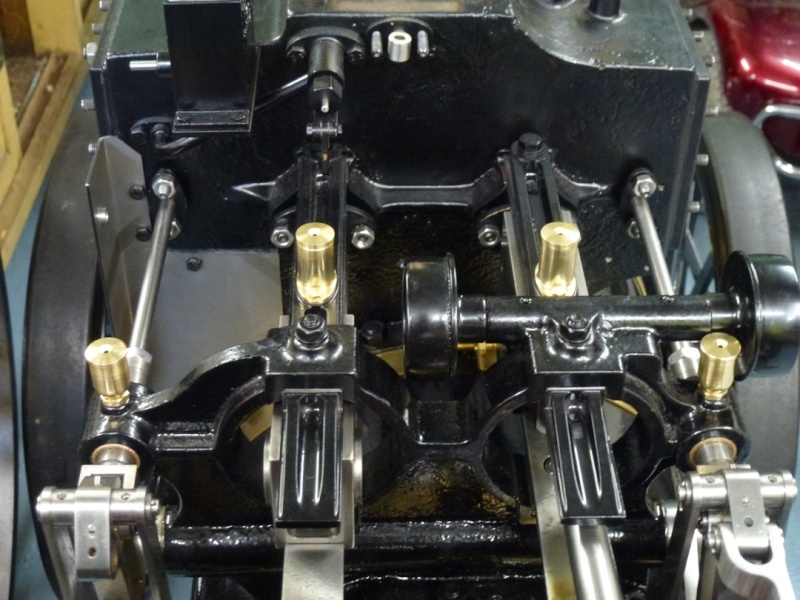

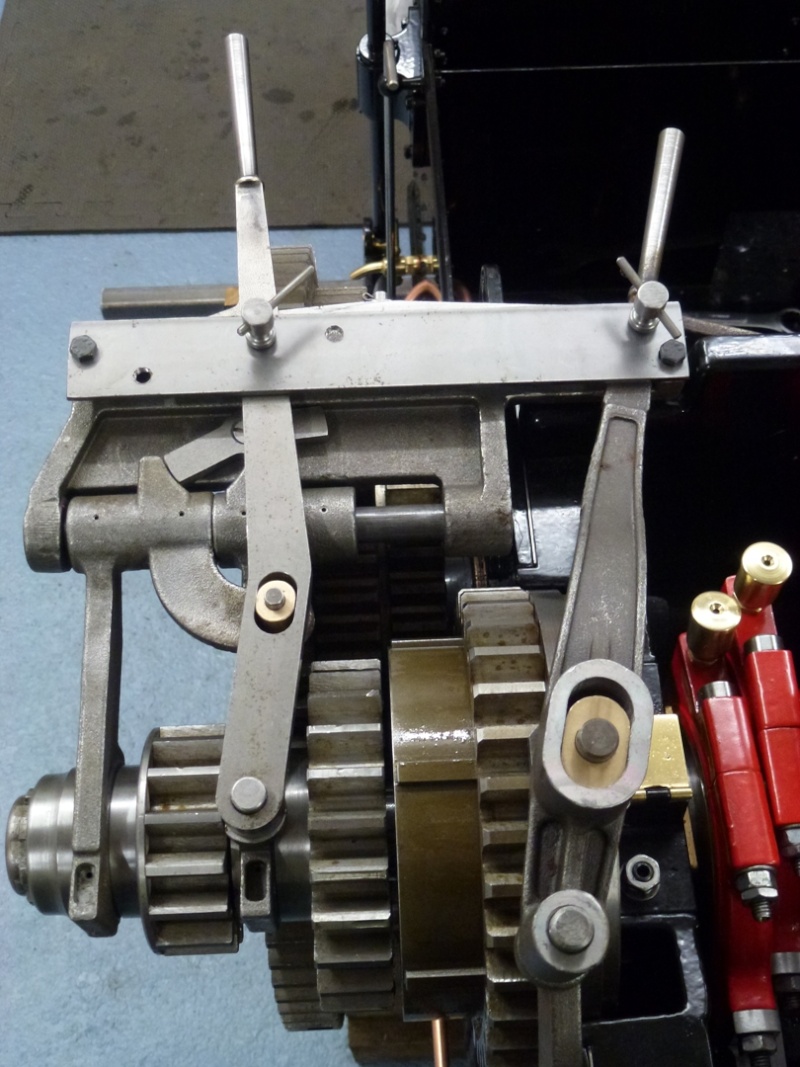

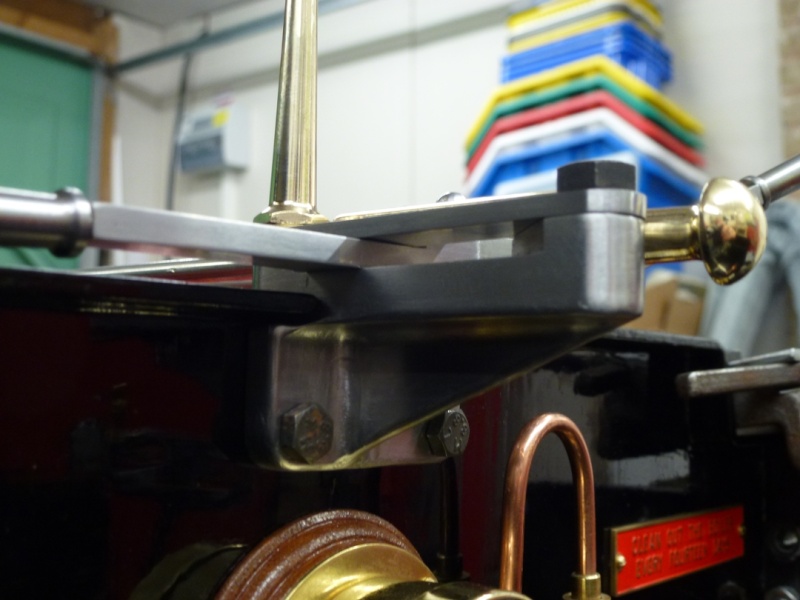

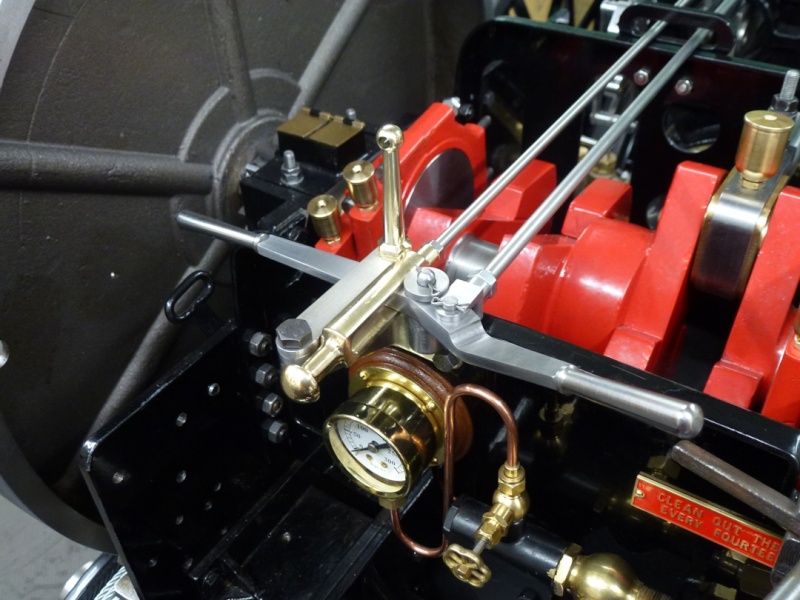

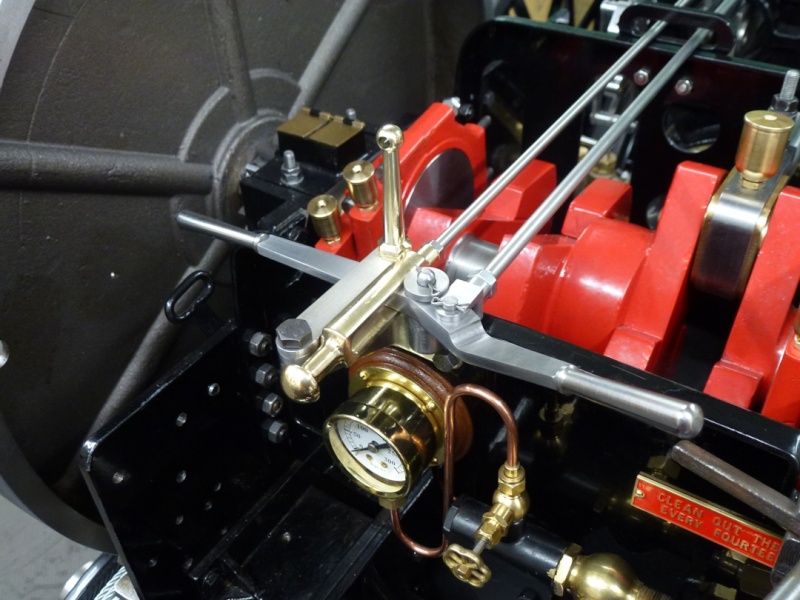

Valve gear has been going back on since the move, a nice emery clothed finish, no bling here. Also, when I drilled the oil holes I drilled a small hole right through the bearing then a larger hole to create a reservoir for more oil.

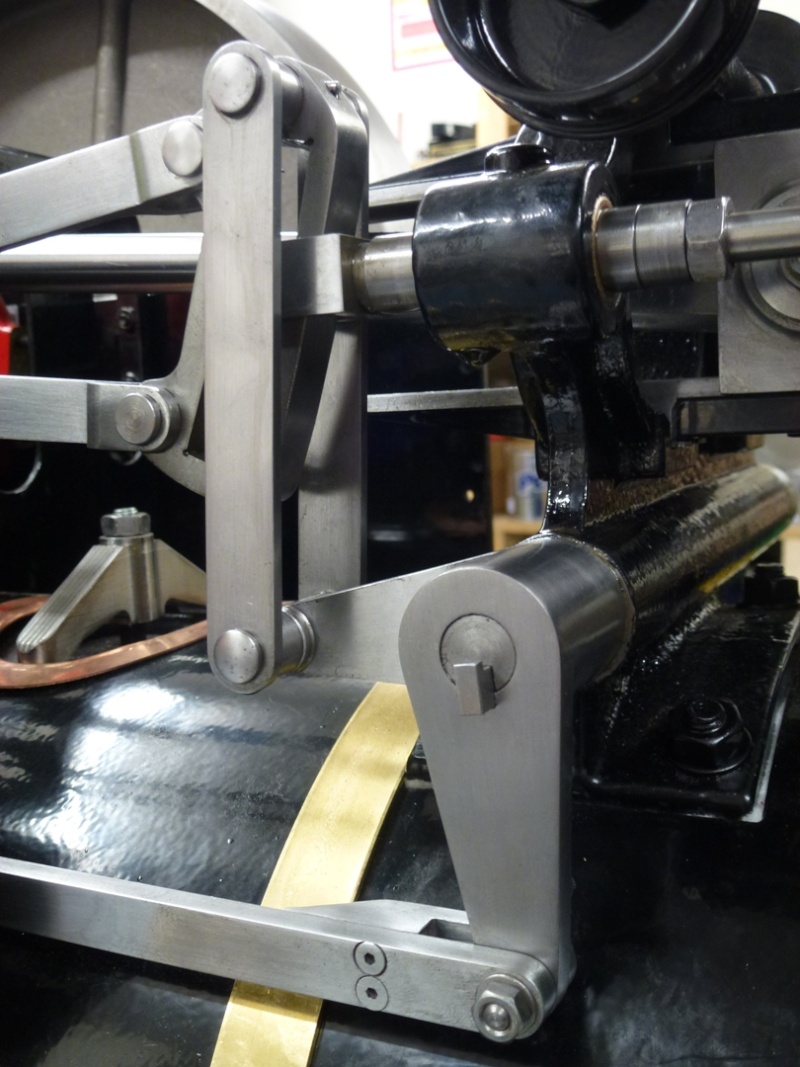

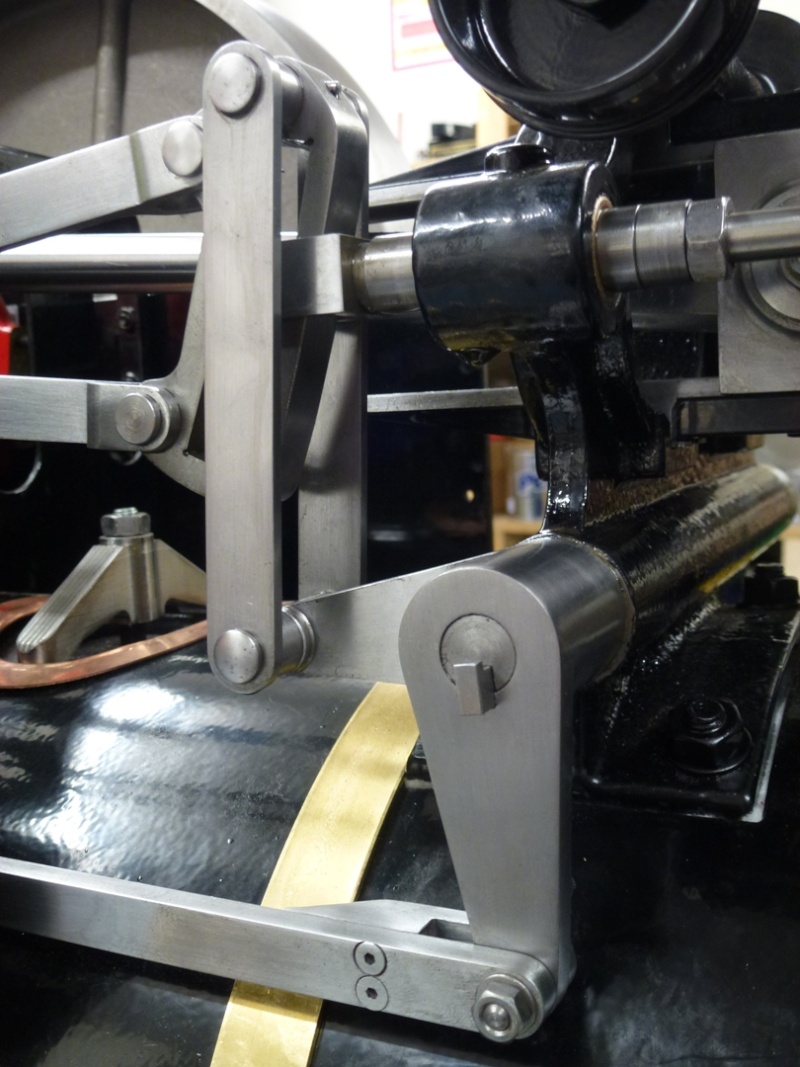

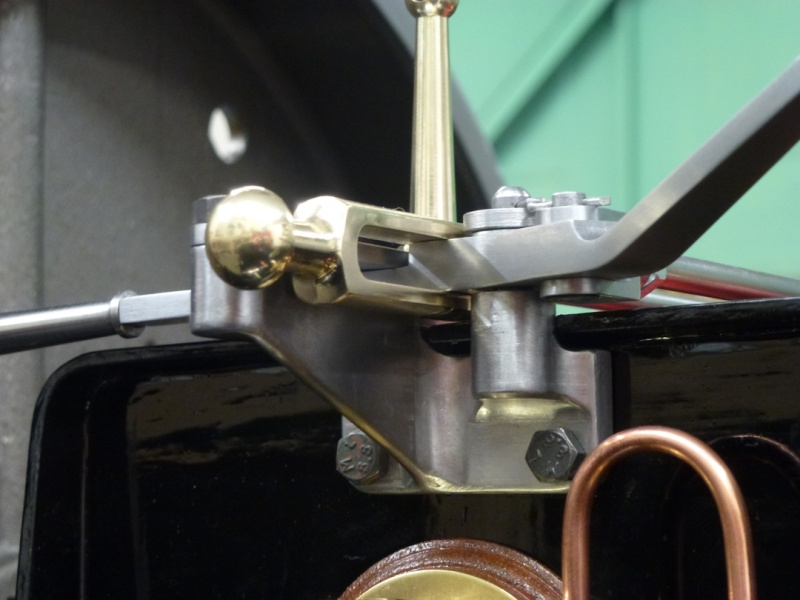

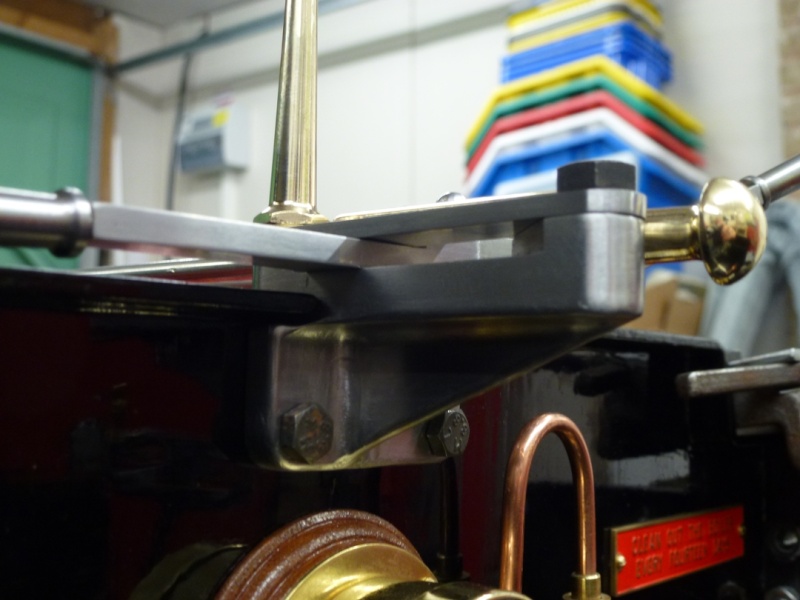

Reach rod and reversing lever are done too, just need to set the position of the cutouts for the reverser. The reversing lever was particularly pleasing once it was finished although a whole weekend as spent on it, a satisfying bit of detail - although I hate painting I love the details. I also filed down the lever so it was the same width as the quadrant as per the full size engine rather than overhanging it - more pictures of this after I get home as they are not all with me.

Finished cylinder end cover detail, I will also be painting the nuts on the valve chest covers once the valves are set and covers finally fitted. I did buy some dome nuts for the covers but once I put them on I did not like the look with all the black around them.

Valve gear has been going back on since the move, a nice emery clothed finish, no bling here. Also, when I drilled the oil holes I drilled a small hole right through the bearing then a larger hole to create a reservoir for more oil.

Reach rod and reversing lever are done too, just need to set the position of the cutouts for the reverser. The reversing lever was particularly pleasing once it was finished although a whole weekend as spent on it, a satisfying bit of detail - although I hate painting I love the details. I also filed down the lever so it was the same width as the quadrant as per the full size engine rather than overhanging it - more pictures of this after I get home as they are not all with me.

bjwlancashire- Number of posts : 938

Location : Mellor, Lancashire

Registration date : 2010-09-07

Re: Road Loco - 'Blackbeard'

Re: Road Loco - 'Blackbeard'

Robfishman wrote:Like the new workshop, very nice. Sounds like you will be pleased to get back to work on the build.

Since those pictures were taken the garage is full again and looking worked in/untidy which ever way you look at it. Good to be busy again and there is a door from the living room to the garage so I am in there as soon as any reality TV shows come on or anything where you vote for celebrities, any DIY or house makeover programmes etc.... In fact I went in for two hours on Christmas Day to avoid Emmerdale/Paul O'Grady.

Lynn, the hatch was indeed for a dog apparently but it is now blocked off.

Cheers

Brian

bjwlancashire- Number of posts : 938

Location : Mellor, Lancashire

Registration date : 2010-09-07

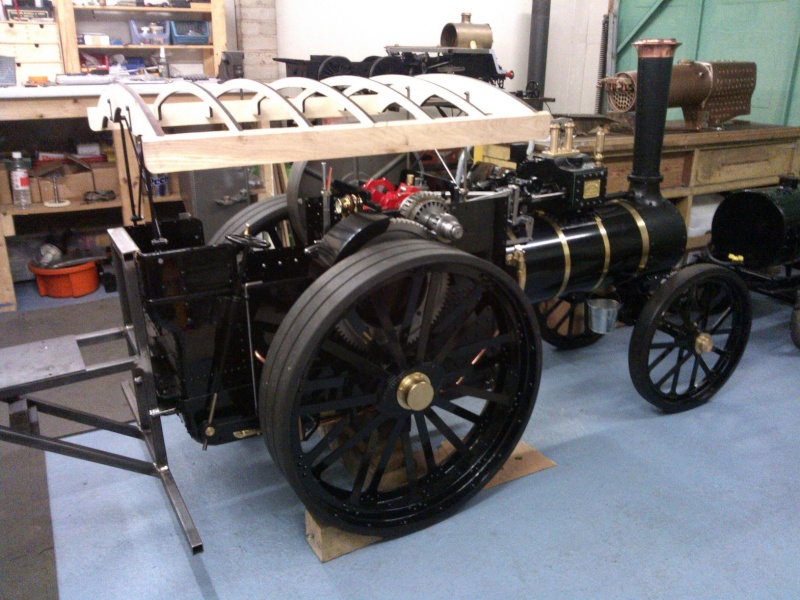

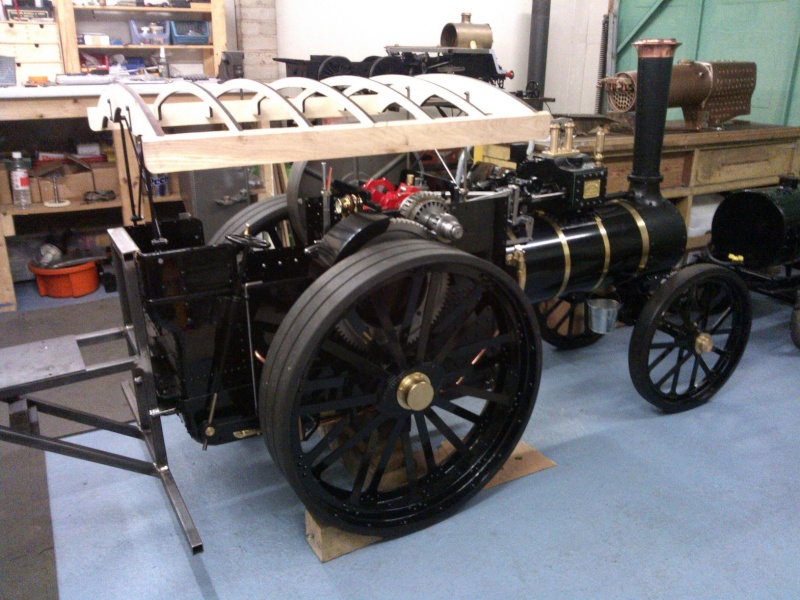

Roof and Belly Tank

Roof and Belly Tank

Please accept my appologies for the quality of some of the following photos as they were taken on my phone rather than my camera.

I got the roof together just before Christmas, well the framework anyway - I used the dining table to keep the framework square as the bench was full!!!!! The slots in the sides are machind so have small radii in the corners and I found that this stopped the cross members from being flush with the top of the side pieces. I had the perfect width of wood chisel so some carefull working of the slots had the corners square and all cross members level with the tops of the side rails.

I used some small ratchet straps to put some tension in the assembly to hold the part together while the recommended Gorilla Glue set. One word of warning about the Gorilla Glue, you need to wet the surfaces to be glued - what happens to wood when it is wet???? As you can imagine the perfect snug fits suddenly became very difficult to assemble and I had applied glue to every slot/cross member end so you can imagine the fight I had to get the parts back together, including careful use of a hide hammer and a block of wood for protection of the surfaces.

The planks were laid on temporarily to see how it looked and also to test my theory regarding a small cutout to aid driving with the roof on to keep the looks of the engine which is quite stunning with the half roof.

Also, I finally got round to putting the belly tank end panels on and adjusted the mounting holes of the angle brackets so I could get it to fit properly. It was fowloing on the second cleading band from the hornplates on the RH side so I could only mount it one hole out of position. It is now with Sonic45 for a liberal coating of Craftmaster gloss black.

Last weekend I finished off all the motion oilers and then made the wicks for each one. I will post some pictures of these once I am back home. I also finally fitted the tender water level taps I had purchased from LSM, as per Sonic45s suggestion.

I got the roof together just before Christmas, well the framework anyway - I used the dining table to keep the framework square as the bench was full!!!!! The slots in the sides are machind so have small radii in the corners and I found that this stopped the cross members from being flush with the top of the side pieces. I had the perfect width of wood chisel so some carefull working of the slots had the corners square and all cross members level with the tops of the side rails.

I used some small ratchet straps to put some tension in the assembly to hold the part together while the recommended Gorilla Glue set. One word of warning about the Gorilla Glue, you need to wet the surfaces to be glued - what happens to wood when it is wet???? As you can imagine the perfect snug fits suddenly became very difficult to assemble and I had applied glue to every slot/cross member end so you can imagine the fight I had to get the parts back together, including careful use of a hide hammer and a block of wood for protection of the surfaces.

The planks were laid on temporarily to see how it looked and also to test my theory regarding a small cutout to aid driving with the roof on to keep the looks of the engine which is quite stunning with the half roof.

Also, I finally got round to putting the belly tank end panels on and adjusted the mounting holes of the angle brackets so I could get it to fit properly. It was fowloing on the second cleading band from the hornplates on the RH side so I could only mount it one hole out of position. It is now with Sonic45 for a liberal coating of Craftmaster gloss black.

Last weekend I finished off all the motion oilers and then made the wicks for each one. I will post some pictures of these once I am back home. I also finally fitted the tender water level taps I had purchased from LSM, as per Sonic45s suggestion.

bjwlancashire- Number of posts : 938

Location : Mellor, Lancashire

Registration date : 2010-09-07

Re: Road Loco - 'Blackbeard'

Re: Road Loco - 'Blackbeard'

Hi

Unfortunately I can not see the pictures.

I also found the belly tank tight but I trimmed the cleading as it was lap joint so I changed it to butt joint and the tank fitted easily.

1 1/2 hours later. Can see the pictures now. Looking great.

Unfortunately I can not see the pictures.

I also found the belly tank tight but I trimmed the cleading as it was lap joint so I changed it to butt joint and the tank fitted easily.

1 1/2 hours later. Can see the pictures now. Looking great.

Last edited by lynnr on Wed 09 Jan 2013, 8:56 am; edited 1 time in total

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Road Loco - 'Blackbeard'

Re: Road Loco - 'Blackbeard'

Brian, I have to say that "all black" is such a good colour for these engines, the overall effect is STUNNING!! As are the eyes of your little driver!! Good to see how your progressing.

Regards,

Tony

Regards,

Tony

Tony King- Number of posts : 856

Age : 69

Location : scotland

Registration date : 2008-10-31

Re: Road Loco - 'Blackbeard'

Re: Road Loco - 'Blackbeard'

Looking good there Brian, reaching completion, hopefully running this year??? I will be interested to see how you fare when trying to actually reach the controls, vision is one thing but the uprights get right in the way to be able to steer and use the regulator. Trust me having had a test drive of my engine this past weekend after fitting the start valve without the roof, initially it was difficult to control the closing of the regulator and it felt like it was going to run away with me and it was TERRIFYING. You suddenly realise that there is NO way to stop instantly and the steering takes forever to go from one side to the other and for a small moment it felt like I was going to crash into next doors car, the fence, my van, pedestrians etc. Be VERY careful when you try the engine for the first few times, especially if this is your first time.

Re: Road Loco - 'Blackbeard'

Re: Road Loco - 'Blackbeard'

That is a lovely engine Brian, well done.

Has anyone heard of the date for the grand STW weekend yet ?

Cheers

Rick

Has anyone heard of the date for the grand STW weekend yet ?

Cheers

Rick

Rickster- Number of posts : 267

Location : canterbury, Kent

Registration date : 2010-02-19

Stealth engines

Stealth engines

Brian:

I like the looks of stealthy plain black engines: unlined engined always seem much bigger than when they are covered with lines! I fully agree with your decision to use plain nuts on the cylinder covers; looks more restrained.

Call in, if your nearby: would love to talk over the remote regulator linkage with you.

Tim

I like the looks of stealthy plain black engines: unlined engined always seem much bigger than when they are covered with lines! I fully agree with your decision to use plain nuts on the cylinder covers; looks more restrained.

Call in, if your nearby: would love to talk over the remote regulator linkage with you.

Tim

Tim Watson- Number of posts : 585

Location : Herts

Registration date : 2008-07-02

Re: Road Loco - 'Blackbeard'

Re: Road Loco - 'Blackbeard'

Tim Watson wrote:Brian:

Call in, if your nearby: would love to talk over the remote regulator linkage with you.

Tim

I am plannig a trip to Basildon which would have been next week but I may defer to the following week. I would love to pay a visit and see Fredrick in the flesh so to speak. I will contact you as soon as the dates are finailsed.

The remote regulator may provide a safer way of driving with the roof on. I have briefly driven Clive Hearsey's engine and clive addmitted himself that his tender is slightly shroter than ours and his canopy also finished just shy of the tender rear edge so blackbeard is more of a reach.

Regards

Brian

Last edited by bjwlancashire on Thu 10 Jan 2013, 1:30 pm; edited 1 time in total

bjwlancashire- Number of posts : 938

Location : Mellor, Lancashire

Registration date : 2010-09-07

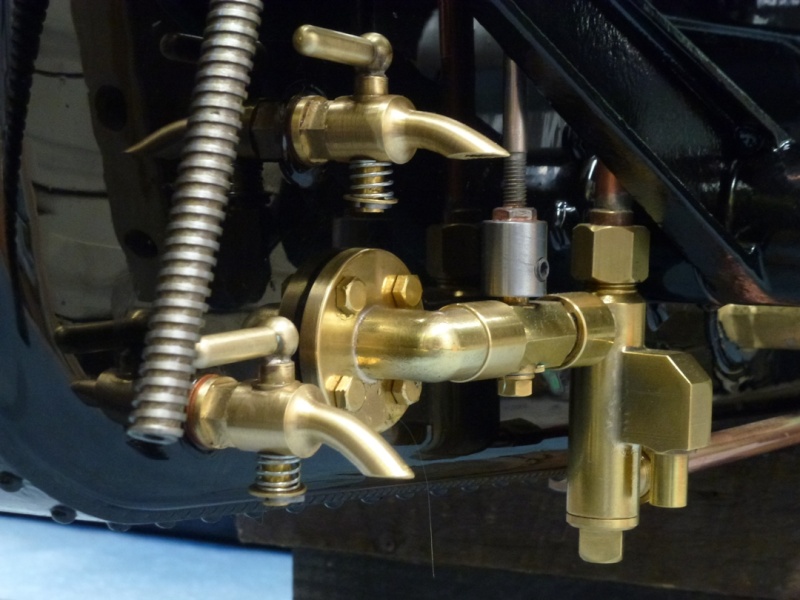

Oilers and Wicks

Oilers and Wicks

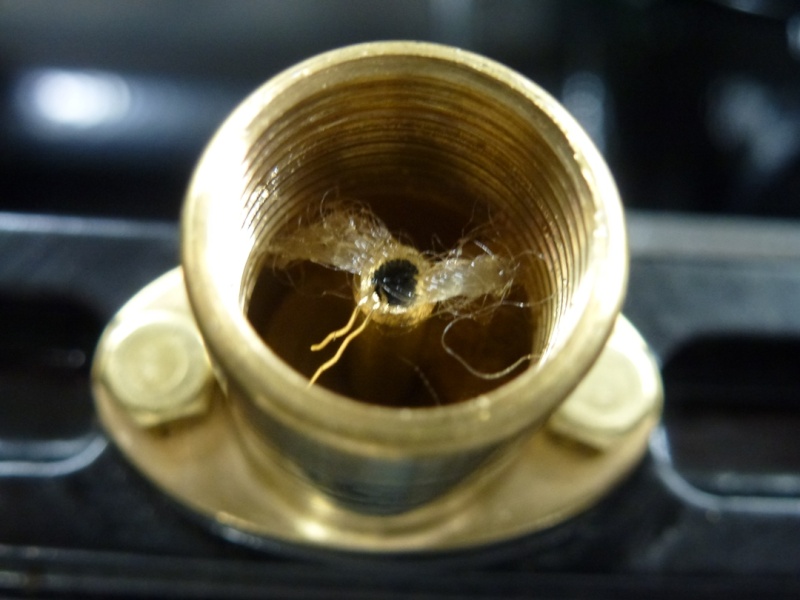

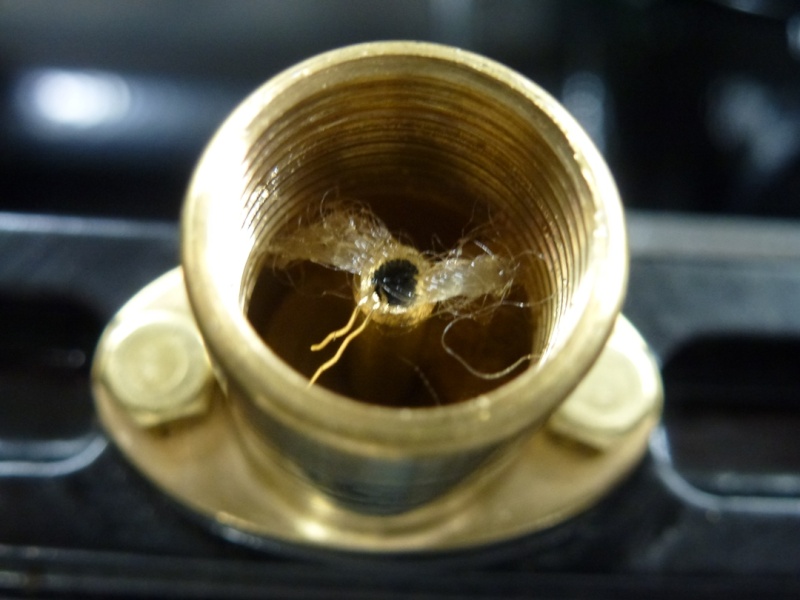

Here are the photos of the oilers now fitted, I did leave them alone for a while but once I got on with them it was quite satisfying. Also, you will see pictures of the wicks in place and the brush I used the bristles from to make the wicks with rather tha just pushing the worsted wool down the hole on its own. The oiler for the HP valve rod next to the govenor pulley is a bit if a fiddle to get the lid on and off - especially with oily hands.

Big end bearing wick

Slide bar oiler, same as eccentric oiler in terms of cup and wick size

Crankshaft bearing LH side, these used the wire that came with the oiler kit from Seddon & Black.

This is the source of the fine wire for the smaller oilers

Big end bearing wick

Slide bar oiler, same as eccentric oiler in terms of cup and wick size

Crankshaft bearing LH side, these used the wire that came with the oiler kit from Seddon & Black.

This is the source of the fine wire for the smaller oilers

bjwlancashire- Number of posts : 938

Location : Mellor, Lancashire

Registration date : 2010-09-07

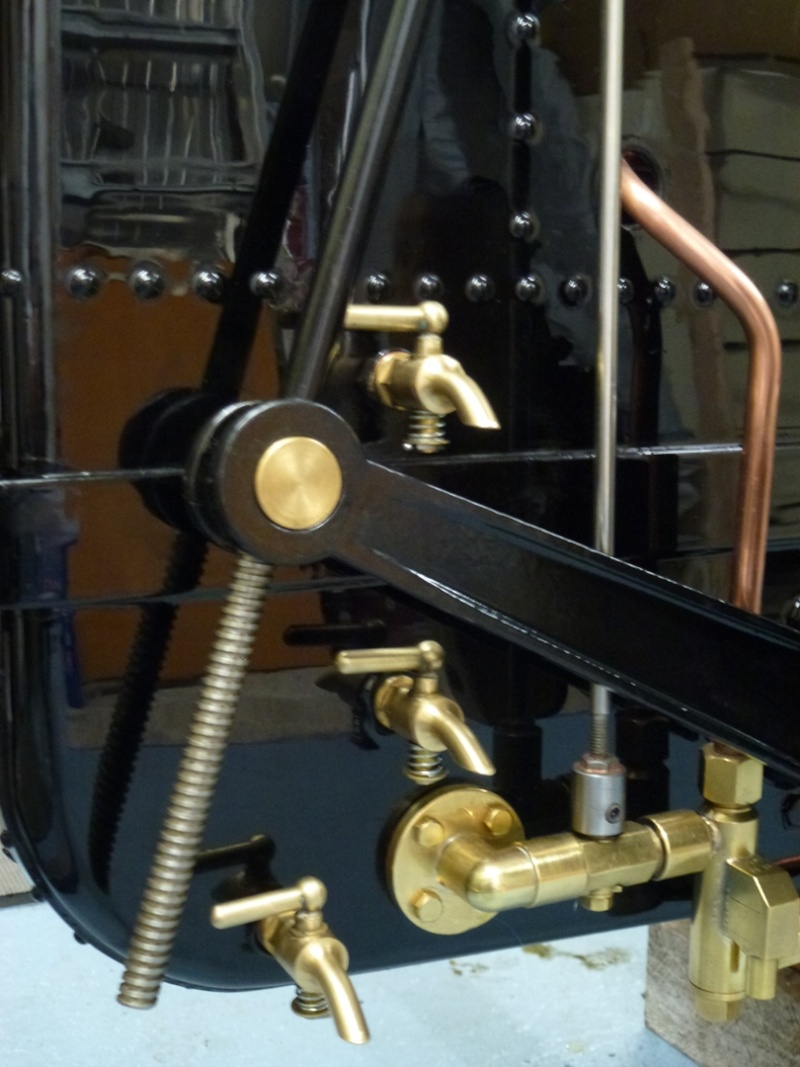

Tender taps now fitted

Tender taps now fitted

I also got around to fitting the tender taps I bought from LSM, they are bigger than the dummy ones from STW and so I had to drill out the holes and tap them to suit, 1/4" BSP. Copper washers were used to ensure the taps tightened in the correct orientation and jointing compound used to seal - to be tested.

I also had to change round my brake shaft as the one I got had been machined twice due to an error. I had originally fitted it this way round first but it seemed wrong but when I had it the other way the brake blocks were only effective with the actuating arm between the middle and lower taps and this only left around an inch of the brake shaft thread left. Also, due to the size of these taps it would have interfered with them.

It is also another excuse to show off SONIC45's excellent paint finish, looking forward to getting the belly tank back soon.

I also had to change round my brake shaft as the one I got had been machined twice due to an error. I had originally fitted it this way round first but it seemed wrong but when I had it the other way the brake blocks were only effective with the actuating arm between the middle and lower taps and this only left around an inch of the brake shaft thread left. Also, due to the size of these taps it would have interfered with them.

It is also another excuse to show off SONIC45's excellent paint finish, looking forward to getting the belly tank back soon.

bjwlancashire- Number of posts : 938

Location : Mellor, Lancashire

Registration date : 2010-09-07

How about this bad boy??????

How about this bad boy??????

With the recent discussions around whistles and what appears to be whistle envy I felt I had to put this picture on the forum. I need to make the necessary adaptions and I know SONIC45 had the same thread size to match for his whistle and it worked fine so wait while you hear this one!!

bjwlancashire- Number of posts : 938

Location : Mellor, Lancashire

Registration date : 2010-09-07

Re: Road Loco - 'Blackbeard'

Re: Road Loco - 'Blackbeard'

Bitch......

Your on Fire now its looking very good Brian, already been pricing the whistle about £250 all in all, these engines will look and NOW sound the business.

cheers

Dwain

Your on Fire now its looking very good Brian, already been pricing the whistle about £250 all in all, these engines will look and NOW sound the business.

cheers

Dwain

Flasback- Number of posts : 191

Location : Cheshire

Registration date : 2011-01-30

Re: Road Loco - 'Blackbeard'

Re: Road Loco - 'Blackbeard'

I think a very quick way of using up all the pressure.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Road Loco - 'Blackbeard'

Re: Road Loco - 'Blackbeard'

Flasback wrote:Bitch......

Your on Fire now its looking very good Brian, already been pricing the whistle about £250 all in all, these engines will look and NOW sound the business.

cheers

Dwain

Cheshire rally is going to get NOISY!! Still can't compete with Lee Fisk's huge chime whistle on his Fowler roller - off a mainline railway locomotive you know.

bjwlancashire- Number of posts : 938

Location : Mellor, Lancashire

Registration date : 2010-09-07

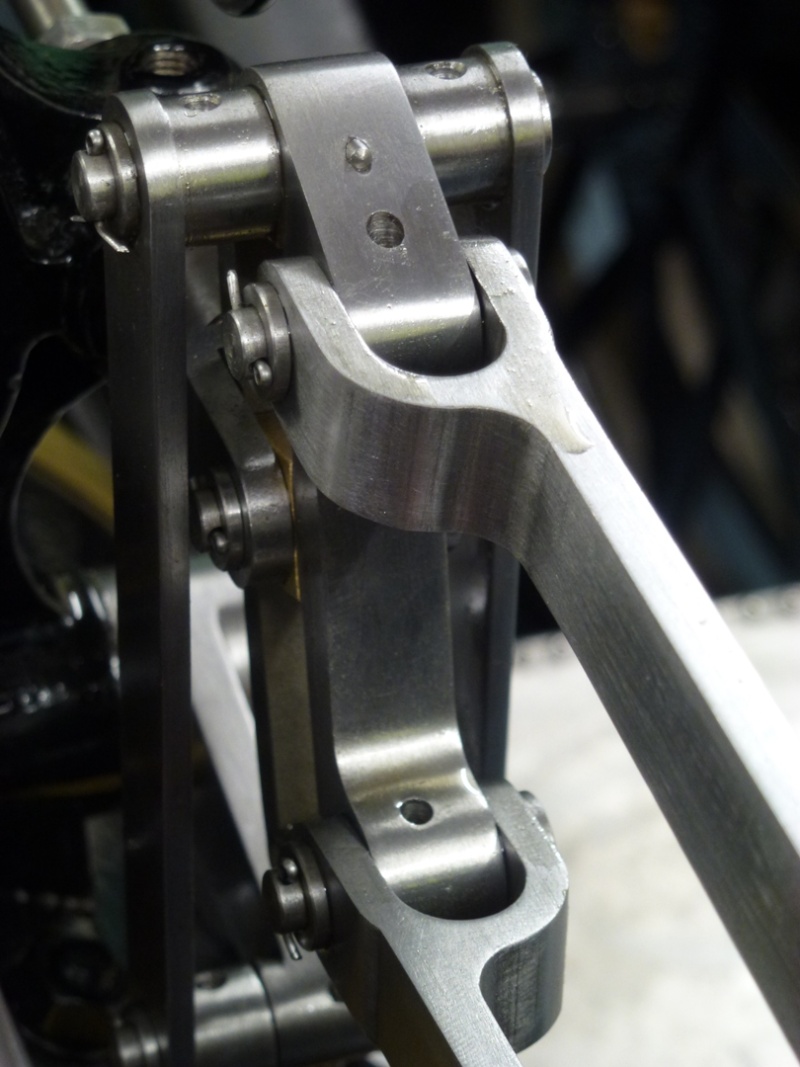

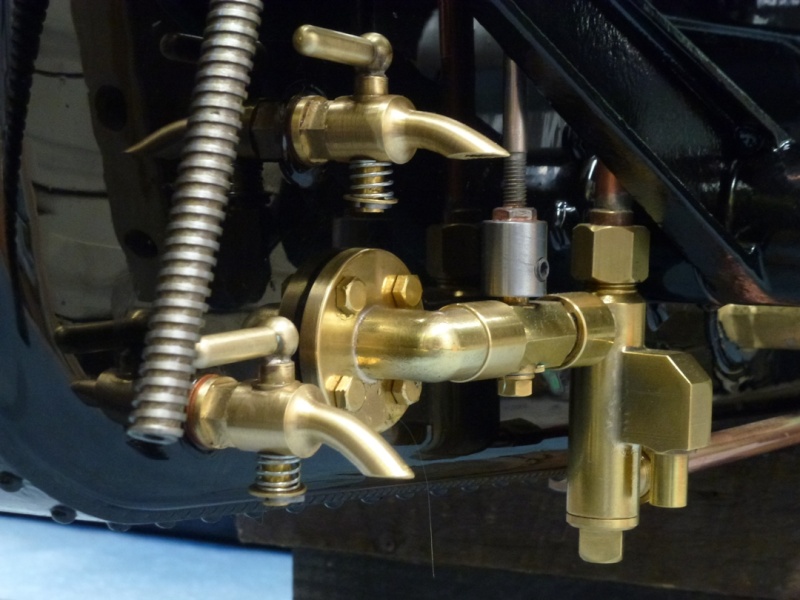

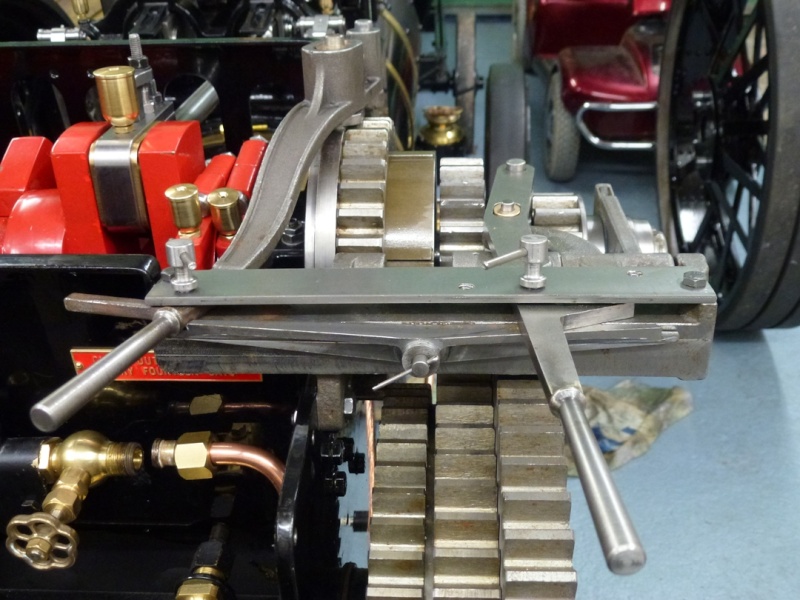

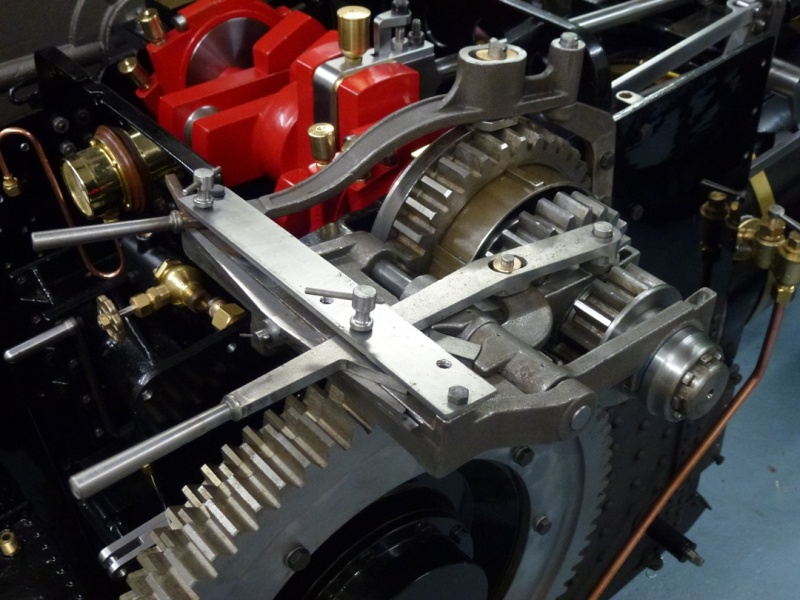

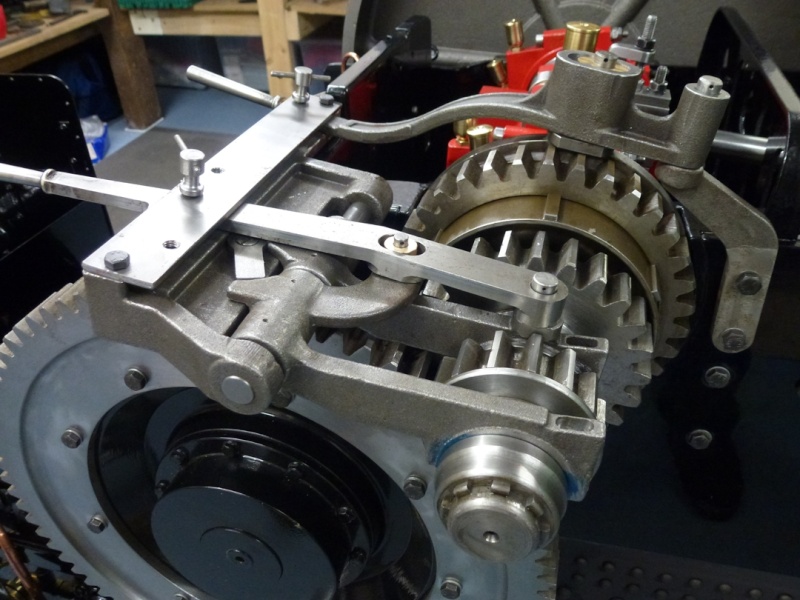

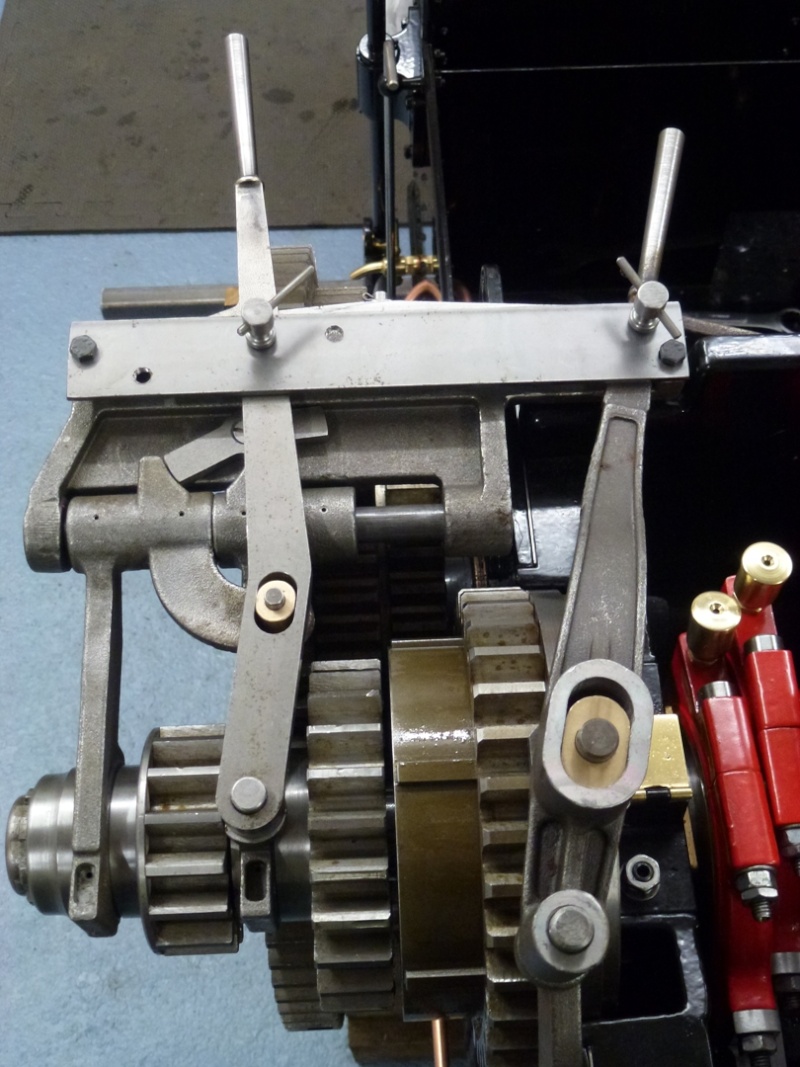

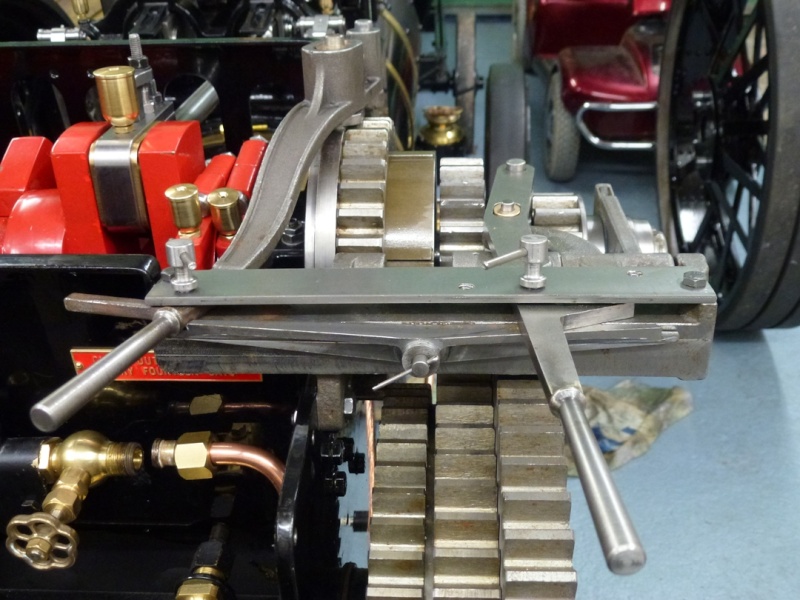

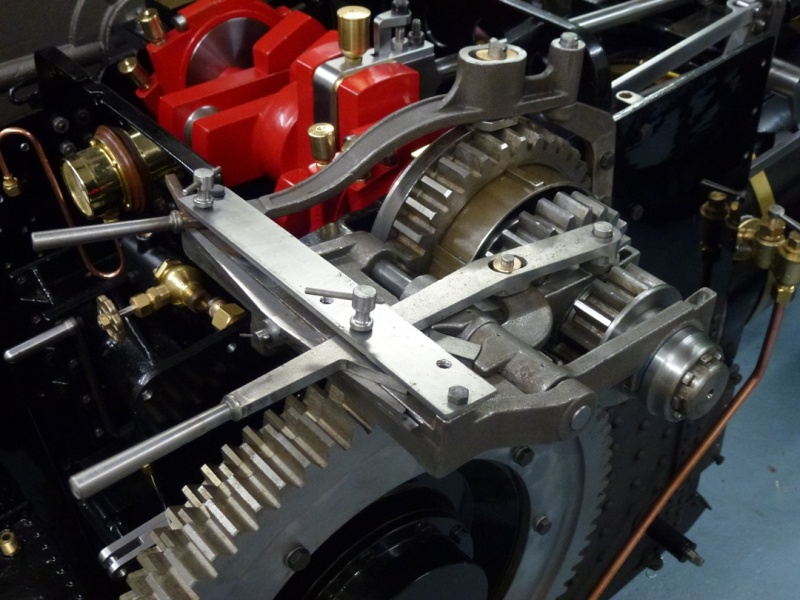

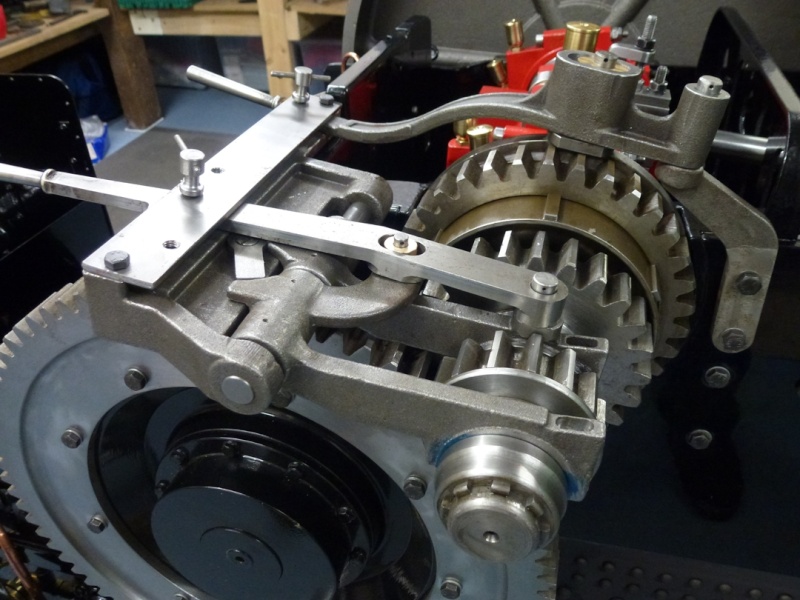

Gear Change Fitted!!

Gear Change Fitted!!

Well, another good workshop session on Friday night into Saturday morning (again). Only the waterpump to fit regulator handle, drain cocks and motion plates to finish with the badges on. Roof will be finsihed off once the rest is done.

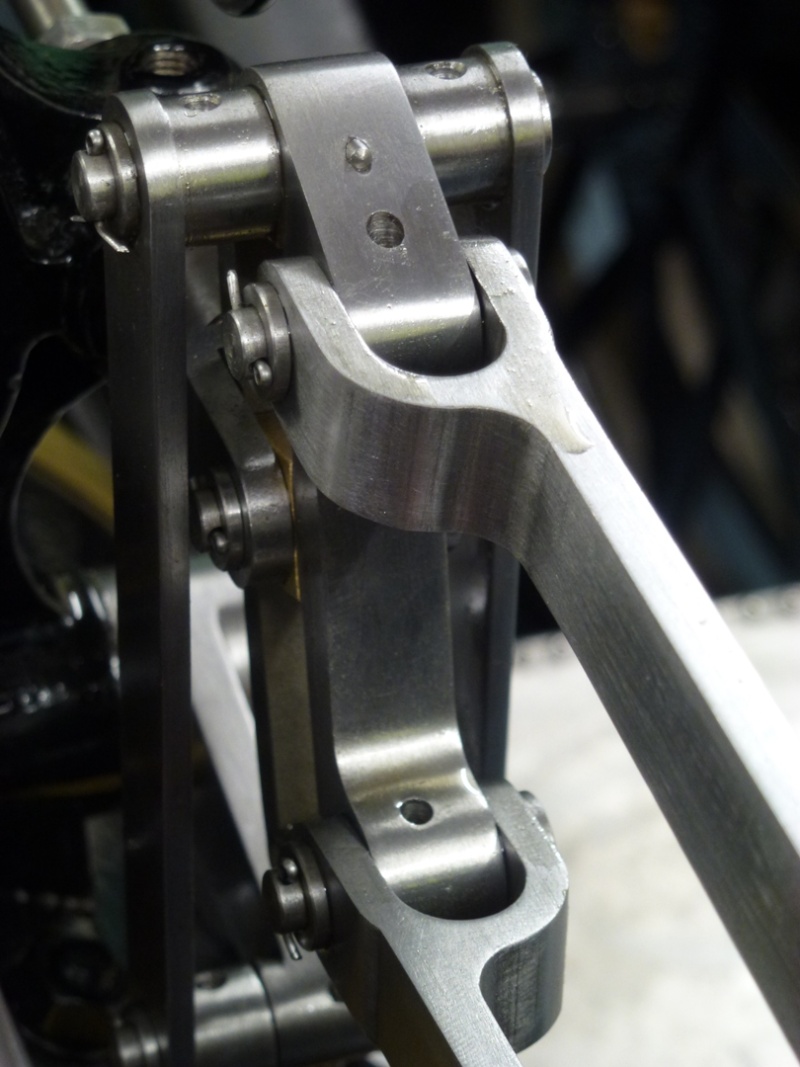

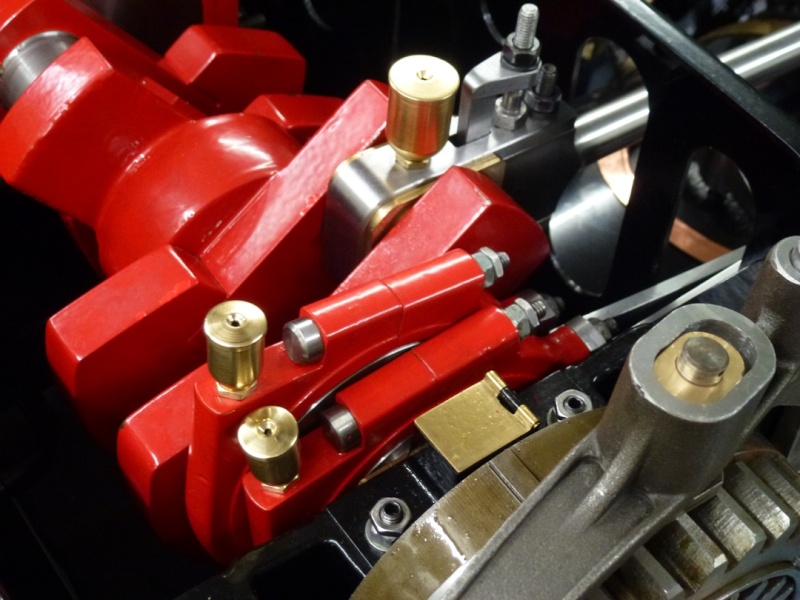

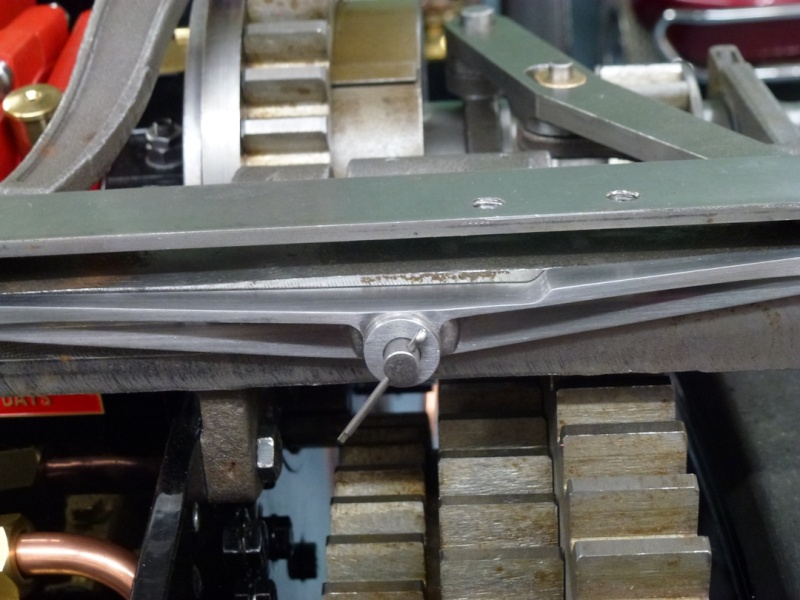

What a struggle to get the second gear selector working smnooth but finally got there after much tweaking. 1st gear was OK first time and 3rd gear just need the handle tweaking as it was slightly higher at the handle end so was gently encouraged to be flat into the main gear change casting. The fixing holes in the locking plate needed opening out a little to get the plat on and allow a small amount of float for best position to get the locking pins in and the 1st/2nd gear lever will need the locking pin slot opening up the slightest amount to allow the pin to go in without holding the lever hard over on the stop.

I will now strip this down and get everything polished or masked for powder coating. Also, I will counterbore the oil holes in the selector forks, the ones that lubricate the bar they slide on. If I drill down three quarters of the way through it will provide a small reservoir to hold the oil as it seems impossible to get any oil in the holes as they are, it just sits on top and then runs off.

Oh by the way, brace yourself for some more colour too, the two gear change handles will be red to match the crank with the rest of the mechanism being black. Interlocking bar will be chemical blackened and the handle straps will be left natural with some deburring and polishing to match the finish of the valve gear. Locking pins will also be polished steel too.

What a struggle to get the second gear selector working smnooth but finally got there after much tweaking. 1st gear was OK first time and 3rd gear just need the handle tweaking as it was slightly higher at the handle end so was gently encouraged to be flat into the main gear change casting. The fixing holes in the locking plate needed opening out a little to get the plat on and allow a small amount of float for best position to get the locking pins in and the 1st/2nd gear lever will need the locking pin slot opening up the slightest amount to allow the pin to go in without holding the lever hard over on the stop.

I will now strip this down and get everything polished or masked for powder coating. Also, I will counterbore the oil holes in the selector forks, the ones that lubricate the bar they slide on. If I drill down three quarters of the way through it will provide a small reservoir to hold the oil as it seems impossible to get any oil in the holes as they are, it just sits on top and then runs off.

Oh by the way, brace yourself for some more colour too, the two gear change handles will be red to match the crank with the rest of the mechanism being black. Interlocking bar will be chemical blackened and the handle straps will be left natural with some deburring and polishing to match the finish of the valve gear. Locking pins will also be polished steel too.

bjwlancashire- Number of posts : 938

Location : Mellor, Lancashire

Registration date : 2010-09-07

Re: Road Loco - 'Blackbeard'

Re: Road Loco - 'Blackbeard'

Brian,

Nice pics...........Just love to see how everyone's engines are coming on....... Heavy metal & shiney stuff..... can't beat it

Looking really good!!

regards,

Tony

Nice pics...........Just love to see how everyone's engines are coming on....... Heavy metal & shiney stuff..... can't beat it

Looking really good!!

regards,

Tony

Tony King- Number of posts : 856

Age : 69

Location : scotland

Registration date : 2008-10-31

Re: Road Loco - 'Blackbeard'

Re: Road Loco - 'Blackbeard'

Brian,

Nice pictures, I really like the brushed / emery cloth finish on the steel, I assume with all the oil flying around in this area it should not rust too much. I am very tempted to do the same with mine when I receive it. I have chemical blacked my steering column and damper rod what have you done with yours.

Ian

Nice pictures, I really like the brushed / emery cloth finish on the steel, I assume with all the oil flying around in this area it should not rust too much. I am very tempted to do the same with mine when I receive it. I have chemical blacked my steering column and damper rod what have you done with yours.

Ian

IanL- Number of posts : 437

Age : 69

Location : Nottinghamshire

Registration date : 2011-07-25

Re: Road Loco - 'Blackbeard'

Re: Road Loco - 'Blackbeard'

Ian

Steering rod and damper rod are both powder coated black, flywheel brakeshaft will be too, it just needs the threads masking

Cheers

Brian

Steering rod and damper rod are both powder coated black, flywheel brakeshaft will be too, it just needs the threads masking

Cheers

Brian

bjwlancashire- Number of posts : 938

Location : Mellor, Lancashire

Registration date : 2010-09-07

Re: Road Loco - 'Blackbeard'

Re: Road Loco - 'Blackbeard'

Brian

Many thanks for the information , wonderd if the paint would cause issues geting it through the two mounting points, hence going down the chemical blacking route.

Ian

Many thanks for the information , wonderd if the paint would cause issues geting it through the two mounting points, hence going down the chemical blacking route.

Ian

IanL- Number of posts : 437

Age : 69

Location : Nottinghamshire

Registration date : 2011-07-25

Re: Road Loco - 'Blackbeard'

Re: Road Loco - 'Blackbeard'

Ian

Steering wheel shaft is what I meant was powdercoated - up to upper bracket anyway. I may paint the top 3" one it is fitted for the final time. The steering chain shaft I also intend to chemical blacken along with the chains and shackles.

Brian

Steering wheel shaft is what I meant was powdercoated - up to upper bracket anyway. I may paint the top 3" one it is fitted for the final time. The steering chain shaft I also intend to chemical blacken along with the chains and shackles.

Brian

bjwlancashire- Number of posts : 938

Location : Mellor, Lancashire

Registration date : 2010-09-07

Re: Road Loco - 'Blackbeard'

Re: Road Loco - 'Blackbeard'

Hi Brian,

I also chemical blacked the chain shaft I used the kit mentioned on earlier posts and created a tank to hold the long items from a length of plastic rain guttering. I blacked the chains and fittings but forgot the two pins that go through the front shackles and axle will need to do them sometime I the future.

Ian

I also chemical blacked the chain shaft I used the kit mentioned on earlier posts and created a tank to hold the long items from a length of plastic rain guttering. I blacked the chains and fittings but forgot the two pins that go through the front shackles and axle will need to do them sometime I the future.

Ian

IanL- Number of posts : 437

Age : 69

Location : Nottinghamshire

Registration date : 2011-07-25

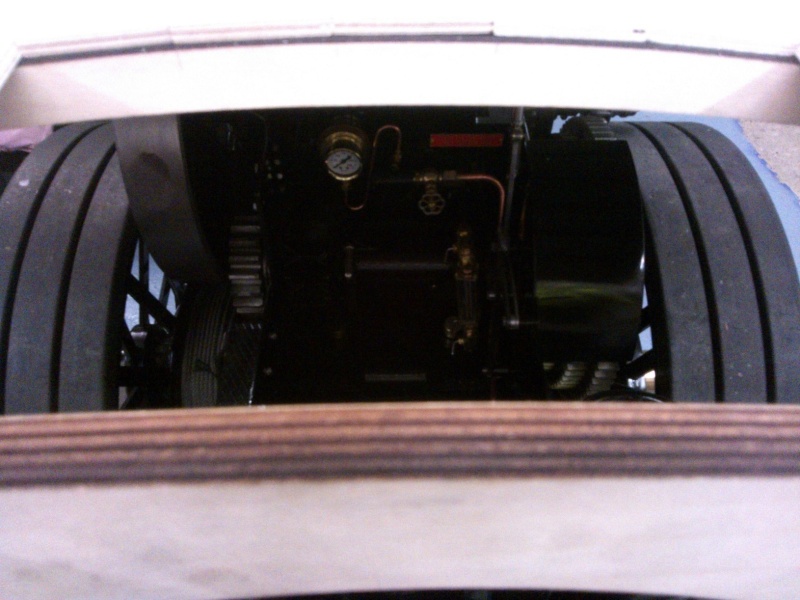

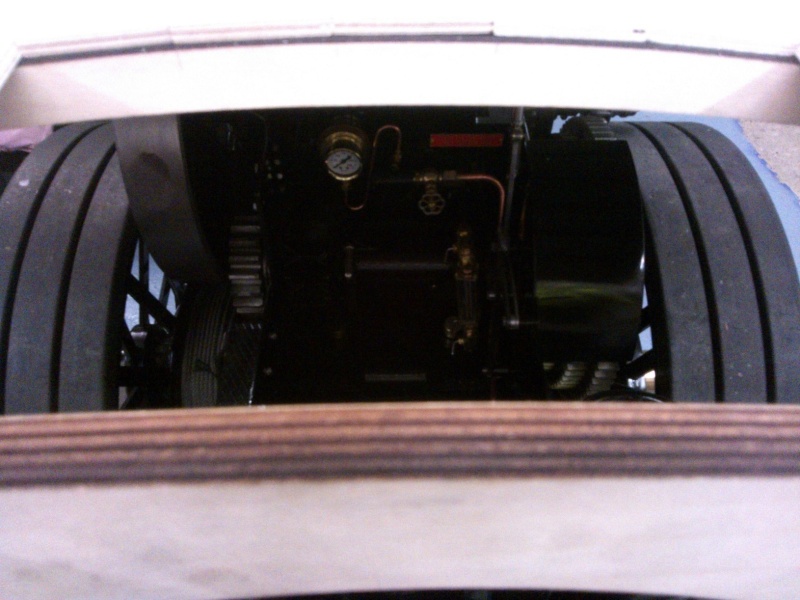

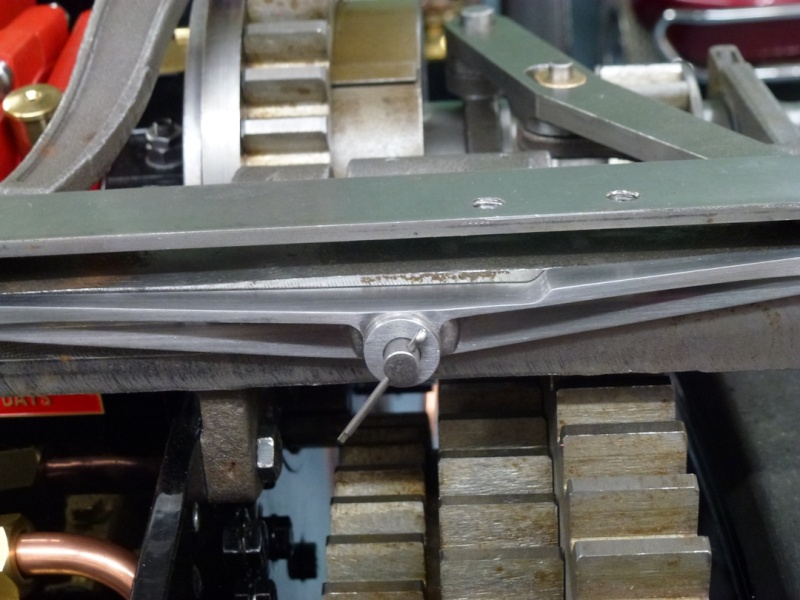

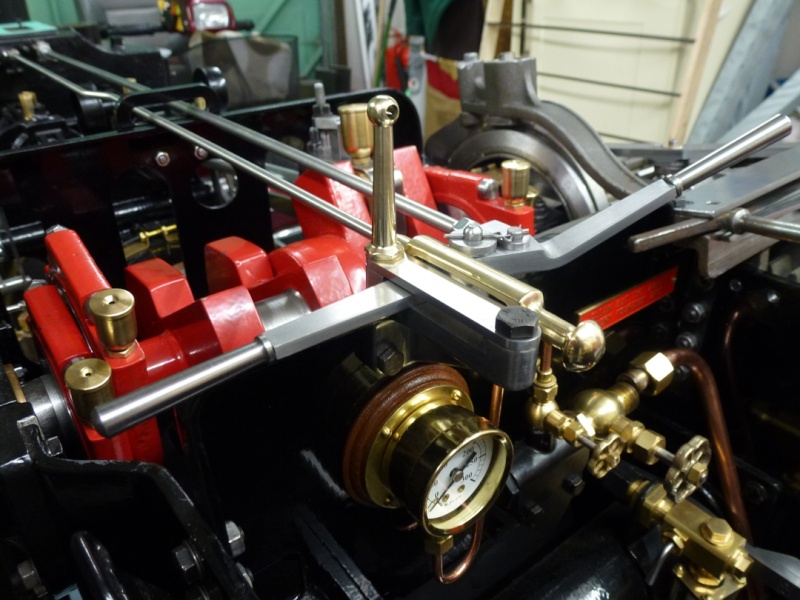

Regulator handle etc..

Regulator handle etc..

Another productive day in the workshop on Sunday!!!

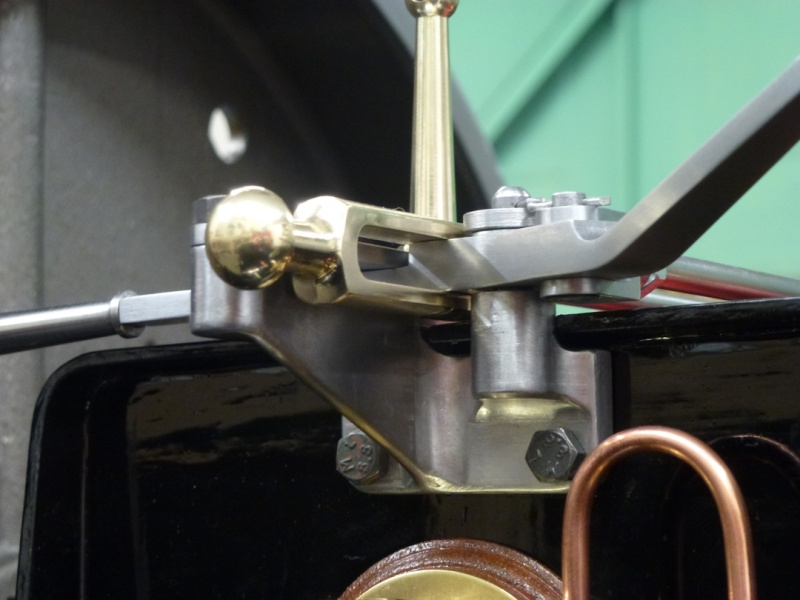

First I fitted the pressure gauge globe valve, a part that had remained in it's bag since it arrived. I then manged to finish polishing the regulator handle bracket and then fit the whole assembly cleaning up all the componenets as I went. I now need to strip it all off again now along with the gear change mechanism to mask parts for powder coating this week.

Blackbeard has a DVLA appointment next Wednesday to be physically inspected prior to getting my registration number so I hope to have the parts back on before I go.

First though I remembered Tim's post regarding the gear change interlocking bar and the cutout he put in to clear the third speed handle so I filed that in and completely cleaned and polished the part ready for final finish.

First I fitted the pressure gauge globe valve, a part that had remained in it's bag since it arrived. I then manged to finish polishing the regulator handle bracket and then fit the whole assembly cleaning up all the componenets as I went. I now need to strip it all off again now along with the gear change mechanism to mask parts for powder coating this week.

Blackbeard has a DVLA appointment next Wednesday to be physically inspected prior to getting my registration number so I hope to have the parts back on before I go.

First though I remembered Tim's post regarding the gear change interlocking bar and the cutout he put in to clear the third speed handle so I filed that in and completely cleaned and polished the part ready for final finish.

bjwlancashire- Number of posts : 938

Location : Mellor, Lancashire

Registration date : 2010-09-07

Page 5 of 17 •  1, 2, 3, 4, 5, 6 ... 11 ... 17

1, 2, 3, 4, 5, 6 ... 11 ... 17

Similar topics

Similar topics» STW 2" road loco

» DCC road loco

» Road Loco wagon

» Andy's 4"dcc road loco

» New Batch 4" DCC Road Loco

» DCC road loco

» Road Loco wagon

» Andy's 4"dcc road loco

» New Batch 4" DCC Road Loco

Page 5 of 17

Permissions in this forum:

You cannot reply to topics in this forum