4" SCC build so far

+12

Mark the spark

LiveSteam

Steve Traill

Kevster

Ian

chas12154

lynnr

Mick1020

Jim the Shovel

ChriX

TimV

Simon B

16 posters

Page 4 of 6

Page 4 of 6 •  1, 2, 3, 4, 5, 6

1, 2, 3, 4, 5, 6

Re: 4" SCC build so far

Re: 4" SCC build so far

Hi Chris

I started with the cross head close to the cylinder with both Pistons fitted and shimmed this until I had a sliding fit, I then went to the other end and shimmed the sliders until I had a running fit. Very fiddly and lots of trial and error. I had to cuts a few more shims from a beer can to open the gap in the slider sufficient to stop the crosshead being jammed between the slides. I then played around with the jacking screws until it slid smoothly along the full travel. Some people have removed metal but I thought it best to shim and then if things loosen up when run in I can remove some shims.

I hope the above helps?

Cheers

Simon

I started with the cross head close to the cylinder with both Pistons fitted and shimmed this until I had a sliding fit, I then went to the other end and shimmed the sliders until I had a running fit. Very fiddly and lots of trial and error. I had to cuts a few more shims from a beer can to open the gap in the slider sufficient to stop the crosshead being jammed between the slides. I then played around with the jacking screws until it slid smoothly along the full travel. Some people have removed metal but I thought it best to shim and then if things loosen up when run in I can remove some shims.

I hope the above helps?

Cheers

Simon

Simon B- Number of posts : 161

Age : 58

Location : Egremont, Cumbria

Registration date : 2014-01-07

Re: 4" SCC build so far

Re: 4" SCC build so far

Hi Tim

Thanks for your reply, that's tomorrow nights trip into the garage sorted. The grub screws will help as the fly wheel slides easily onto the crank shaft and even with the key nearly fully home there is a bit of movement when I turn it back and forth.

Best wishes

Simon

Thanks for your reply, that's tomorrow nights trip into the garage sorted. The grub screws will help as the fly wheel slides easily onto the crank shaft and even with the key nearly fully home there is a bit of movement when I turn it back and forth.

Best wishes

Simon

Simon B- Number of posts : 161

Age : 58

Location : Egremont, Cumbria

Registration date : 2014-01-07

Re: 4" SCC build so far

Re: 4" SCC build so far

Hi Chris, Simon.

Lining up crosshead.

This is how i did it, not sure if it was the correct way but it seems to work

loosely fitted slide bar support with pistons fitted and screwed into crosshead, position them at front of bore then i just fitted the bottom slide bars and made sure that they were a nice fit on the bottom of crosshead, then i moved the crosshead so that the pistons were at rear of bore, then adjusted slide bar support to make the guide bars fit nicely under the crosshead in this position after this i fitted both top slide bars and made sure it moved back and forth freely had to shim it out with extra shims than were supplied as also when i lined up the bottom ones.

I then got 2 steel rules , put one across the flat surface of the regulator/safety valve face and then measured down to the tops of the slide bars at front and back with the other rule, im assuming that this face would be parallel to the bores so doing this will ensure all is running on the same angle as the cylinder is very slightly tipping back, the measurement for this worked out at about 83mm/83.5 so the guide bars are pretty square to the block.

Hope this is of help to you, its difficult to try and explain!! its easier to actually do, I spent the best part of 2 days trying to line it all up.

Good luck

Tim

Lining up crosshead.

This is how i did it, not sure if it was the correct way but it seems to work

loosely fitted slide bar support with pistons fitted and screwed into crosshead, position them at front of bore then i just fitted the bottom slide bars and made sure that they were a nice fit on the bottom of crosshead, then i moved the crosshead so that the pistons were at rear of bore, then adjusted slide bar support to make the guide bars fit nicely under the crosshead in this position after this i fitted both top slide bars and made sure it moved back and forth freely had to shim it out with extra shims than were supplied as also when i lined up the bottom ones.

I then got 2 steel rules , put one across the flat surface of the regulator/safety valve face and then measured down to the tops of the slide bars at front and back with the other rule, im assuming that this face would be parallel to the bores so doing this will ensure all is running on the same angle as the cylinder is very slightly tipping back, the measurement for this worked out at about 83mm/83.5 so the guide bars are pretty square to the block.

Hope this is of help to you, its difficult to try and explain!! its easier to actually do, I spent the best part of 2 days trying to line it all up.

Good luck

Tim

TimV- Number of posts : 123

Location : Poole , Dorset

Registration date : 2014-10-09

Re: 4" SCC build so far

Re: 4" SCC build so far

Simon B wrote:Finished painting and then temporarily fitted the fly wheel. I was following the instruction when they said fit the flywheel keyway and the 6mm grub screw?? there is no 6mm grub screw or tapped hole for it to fit in, so at the moment I'm unsure how to stop the flywheel sliding on the crankshaft. Am I missing something, what have others done??

You are not missing anything the key is tapered and should lock the flywheel in place, the mentioned grub screw is a leftover from porting the instruction from the 4" agricultural instructions that we missed. If you are worried about the keys tightness put a bit of shim under it, or if you wish fit a grub screw.

Ian- Number of posts : 113

Age : 68

Location : Daventry

Registration date : 2008-06-30

Re: 4" SCC build so far

Re: 4" SCC build so far

Thanks Ian,

I'll see how the fit is when I finally fit the flywheel and fully knock home the key, before getting my drill out and risk damaging the paint.

Cheers

Simon

I'll see how the fit is when I finally fit the flywheel and fully knock home the key, before getting my drill out and risk damaging the paint.

Cheers

Simon

Simon B- Number of posts : 161

Age : 58

Location : Egremont, Cumbria

Registration date : 2014-01-07

Re: 4" SCC build so far

Re: 4" SCC build so far

Cheers Tim and Simon; a great help from you both. I have the day off work Friday so will have another play then.

ChriX- Number of posts : 90

Age : 39

Location : Cornwall, UK

Registration date : 2012-06-22

4" SCC build so far

4" SCC build so far

Hi All

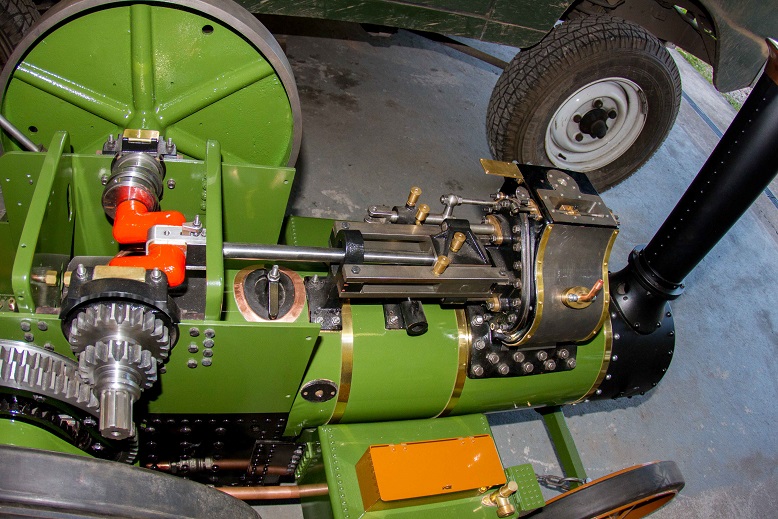

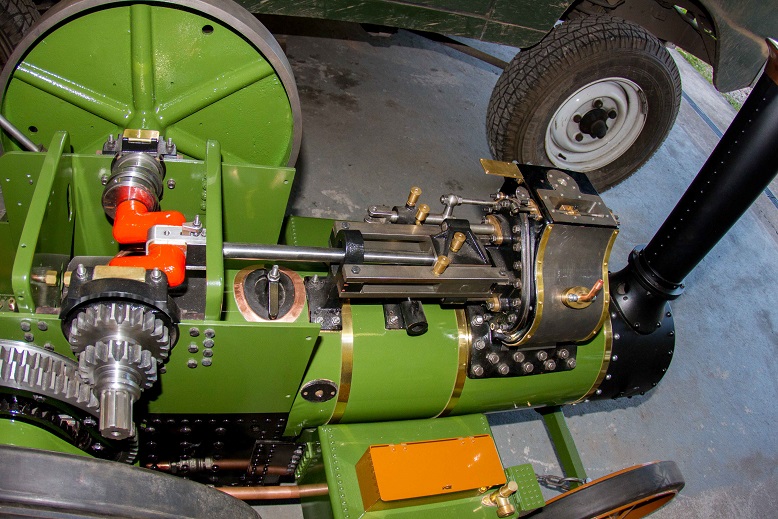

Finally got around to painting the final drive guards and the rear wheels. The guards fitted well but when I tried to turn the crank everything locked up, after removing the guards the clearance between the gears and the guards is really small so I had to grind off the excess rivet bolt and thin down the nuts slightly but all fits well now

I'm not going to refit the rear near side wheel yet as I'm not sure if the flywheel needs to be removed again or not?

Also trial fitted the cylinder cladding, bit fiddly and needed to reshape the cladding a bit but I'm pleased with the final fit, more painting this week then!!

Finally got around to painting the final drive guards and the rear wheels. The guards fitted well but when I tried to turn the crank everything locked up, after removing the guards the clearance between the gears and the guards is really small so I had to grind off the excess rivet bolt and thin down the nuts slightly but all fits well now

I'm not going to refit the rear near side wheel yet as I'm not sure if the flywheel needs to be removed again or not?

Also trial fitted the cylinder cladding, bit fiddly and needed to reshape the cladding a bit but I'm pleased with the final fit, more painting this week then!!

Simon B- Number of posts : 161

Age : 58

Location : Egremont, Cumbria

Registration date : 2014-01-07

4" SCC build so far

4" SCC build so far

After looking at Charlie's 2" colour scheme and the way he has highlighted the beading on the tender I thought the plain green was just that a bit plain so decided to follow suit and highlight my tender beading in black, it looks much better but still not to sure (confident) about lining the engine up.

In the end I decided to fit the other rear wheel as it makes the engine mobile again.

The ash pan and damper rod are now painted and fitted so now just need to paint the steering and the cylinder cladding to get up to date, saying that it's a cracking evening in the lakes so it won't get painted tonight

In the end I decided to fit the other rear wheel as it makes the engine mobile again.

The ash pan and damper rod are now painted and fitted so now just need to paint the steering and the cylinder cladding to get up to date, saying that it's a cracking evening in the lakes so it won't get painted tonight

Simon B- Number of posts : 161

Age : 58

Location : Egremont, Cumbria

Registration date : 2014-01-07

Re: 4" SCC build so far

Re: 4" SCC build so far

Looking very nice indeed

Kev

Kev

Kevster- Number of posts : 424

Location : Hertfordshire 4 inch; DCC road loco

Registration date : 2011-01-27

Re: 4" SCC build so far

Re: 4" SCC build so far

Looking very nice, the clearance on the gear guards has always been tight if not non-existant! I've had to reduce the heads of several rivets so you don't get the clicking sound when driving. I like the curve on the cylinder cladding, sets the whole engine off nicely, good colour scheme too.

Steve Traill- Number of posts : 800

Age : 67

Location : Illogan Redruth Cornwall

Registration date : 2008-06-29

Re: 4" SCC build so far

Re: 4" SCC build so far

Hi Kev and Steve

Thanks for your comments much appreciated, hopefully be in steam by the end of summer / Autumn really looking forward to that day.

Cheers

Simon

Thanks for your comments much appreciated, hopefully be in steam by the end of summer / Autumn really looking forward to that day.

Cheers

Simon

Simon B- Number of posts : 161

Age : 58

Location : Egremont, Cumbria

Registration date : 2014-01-07

Re: 4" SCC build so far

Re: 4" SCC build so far

Thats really "popped" the green out putting the black on the beading

LiveSteam- Number of posts : 788

Location : Hampshire

Registration date : 2013-09-08

4" SCC build so far

4" SCC build so far

Hi All

The last few weeks I've been chemically blackening and painting bits and pieces. Tonight I refitted all of the parts, and just in time as I've just received a text from HQ another kits arriving tomorrow

.

.

Rather than paint the big end bracket, bolts and wedge I blackened them, hopefully there will be enough oil around here to prevent it going rusty in a few months

The fire doors have been refitted, before blackening them I removed a few burrs and rounded the corners off, they now operate smoothly without sticking at either end of the travel

The steering components have either been blackened or painted, now that the oilers have been fitted and oil applied to the bearings the steering is smoother with no binding.

Cylinder cladding painted an refitted, the cylinder bolts and the smoke box rivets have also been painted

I hope everybody else's builds are going well.

Simon

The last few weeks I've been chemically blackening and painting bits and pieces. Tonight I refitted all of the parts, and just in time as I've just received a text from HQ another kits arriving tomorrow

Rather than paint the big end bracket, bolts and wedge I blackened them, hopefully there will be enough oil around here to prevent it going rusty in a few months

The fire doors have been refitted, before blackening them I removed a few burrs and rounded the corners off, they now operate smoothly without sticking at either end of the travel

The steering components have either been blackened or painted, now that the oilers have been fitted and oil applied to the bearings the steering is smoother with no binding.

Cylinder cladding painted an refitted, the cylinder bolts and the smoke box rivets have also been painted

I hope everybody else's builds are going well.

Simon

Simon B- Number of posts : 161

Age : 58

Location : Egremont, Cumbria

Registration date : 2014-01-07

4" SCC build so far

4" SCC build so far

Ooops, not sure why the photographs have uploaded out of order!!!

Simon B- Number of posts : 161

Age : 58

Location : Egremont, Cumbria

Registration date : 2014-01-07

Re: 4" SCC build so far

Re: 4" SCC build so far

Looking really good.

Steve Traill- Number of posts : 800

Age : 67

Location : Illogan Redruth Cornwall

Registration date : 2008-06-29

Re: 4" SCC build so far

Re: 4" SCC build so far

Nice work Simon, I'm at the same stage with "valiant" and also should be receiving another kit today.

TimV- Number of posts : 123

Location : Poole , Dorset

Registration date : 2014-10-09

Re: 4" SCC build so far

Re: 4" SCC build so far

Try and make it so the fire doors are easily removeable. 'R' clips instead of split pins etc. With the agricultural they are prone to building up a layer of burnt oil on the back making them very stiff. A Stanley blade gets them clean but it's tricky with them in place. I have done it with the engine cold & putting my hand up inside the firebox. You get a black arm though!

Steve Traill- Number of posts : 800

Age : 67

Location : Illogan Redruth Cornwall

Registration date : 2008-06-29

Re: 4" SCC build so far

Re: 4" SCC build so far

I did not paint mine but instead cleaned them to bright metal. Panel wiped then heated them right up and put them in a oil bath to cool.

Not had much problem with crud sticking to them for 3 years now.

Not had much problem with crud sticking to them for 3 years now.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: 4" SCC build so far

Re: 4" SCC build so far

Not had any sticky doors on 2yrs of ownership of a 11yr old MW Agri either, sometime they can feel a little sludgy or mildly stiff when cold but once the fires going they are as free as a bird.

LiveSteam- Number of posts : 788

Location : Hampshire

Registration date : 2013-09-08

Re: 4" SCC build so far

Re: 4" SCC build so far

It's funny, on the Road Loco I don't get the sticking doors but on the agricultural I do. I know several others that get the same problem. The stuff on the inside of the doors is baked on and needs a sharp Stanley blade to remove it. It's then sort of white powdery baked on stuff. Not something that works itself away. It's not soot from the fire as that is easily removed, it might be oil off the crank running inside the doors & baking on somehow. I'm open to anyone's theories on this as it's still a bit of a mystery?! I just know that 2 - 3 times a season I have to remove the doors to get them free running again. Doesn't happen on the RL though???

Steve Traill- Number of posts : 800

Age : 67

Location : Illogan Redruth Cornwall

Registration date : 2008-06-29

4" SCC build so far

4" SCC build so far

Good evening all

Thanks everybody for your advice and experiences with fire doors

Steve thanks for your advice about using 'R' clips, they will be much easier to remove and also look a lot neater than the split pins not only on the fire doors but also on the valve gear.

Lynn, I thought about oil blueing rather than chemical blacking, if the chemical finish starts to rust I'll follow your lead and oil blue next time.

Talking about finish tonight I've fitted the valve gear, I'm in two minds whether to paint it, leave it plain steel and wipe I with oil or blacken it again what have other people done?

The valve gear went together really well just needed to remove a few burrs but no lapping in required for the eccentric's, when I tightened the bolts completely they are a bit tight but I presume they will loosen off once I start to use the engine

Thanks everybody for your advice and experiences with fire doors

Steve thanks for your advice about using 'R' clips, they will be much easier to remove and also look a lot neater than the split pins not only on the fire doors but also on the valve gear.

Lynn, I thought about oil blueing rather than chemical blacking, if the chemical finish starts to rust I'll follow your lead and oil blue next time.

Talking about finish tonight I've fitted the valve gear, I'm in two minds whether to paint it, leave it plain steel and wipe I with oil or blacken it again what have other people done?

The valve gear went together really well just needed to remove a few burrs but no lapping in required for the eccentric's, when I tightened the bolts completely they are a bit tight but I presume they will loosen off once I start to use the engine

Simon B- Number of posts : 161

Age : 58

Location : Egremont, Cumbria

Registration date : 2014-01-07

Re: 4" SCC build so far

Re: 4" SCC build so far

If you plate it I found that the tolerances needed adjusting. The plating makes the outside edges thicker, doesn't really make holes smaller so I guess it doesn't get in there. The nickel plating looks nice but in reality all that motion work will be covered in oil most of the time. Unless you're going to leave the engine out in the rain regularly it probably won't get rusty. Most of the builders I think have plated the motion work just to be on the safe side. I've had mixed results with the home brew plating kits, some was great, other bits were dire! All eaten away and made the steel look like bark! For the RL I sent most of the plating to the guy in Portsmouth that Steve B recommended. Great job, cheap for cash, no hassle.

Steve Traill- Number of posts : 800

Age : 67

Location : Illogan Redruth Cornwall

Registration date : 2008-06-29

Re: 4" SCC build so far

Re: 4" SCC build so far

Thanks Steve

I've already bought a nickel plating kit, but will first see if I can find somebody locally who does nickel plating.

Best wishes

Simon

I've already bought a nickel plating kit, but will first see if I can find somebody locally who does nickel plating.

Best wishes

Simon

Simon B- Number of posts : 161

Age : 58

Location : Egremont, Cumbria

Registration date : 2014-01-07

Re: 4" SCC build so far

Re: 4" SCC build so far

Simon B wrote:

Talking about finish tonight I've fitted the valve gear, I'm in two minds whether to paint it, leave it plain steel and wipe I with oil or blacken it again what have other people done?

None of my valve gear or conrod, slides etc are plated, there are a few bits like the reversing leaver for instance and the drain valve rod is but the rest is just steel, it soon gets a layer of oil baked on it when running anyway. If I want to bling it up a bit then a little puff of WD40 and a green scratchy (you know the thing that your partner uses to wear the pattern off the plates when washing up) soon brings them up nice and shiney again.........only for them to get very quickly covered in oil again

The plated items get just as grubby. Although I have to say I go for a "working engine" look to one thats just come out of the factory, that and I hate cleaning and polishing

LiveSteam- Number of posts : 788

Location : Hampshire

Registration date : 2013-09-08

Re: 4" SCC build so far

Re: 4" SCC build so far

Hi Livesteam

Thanks for your post, it's good to know that there are options, I quite like the plain steel look. I've found a nickel plating place near to where I live but will wait until I get all of the levers and other steel bits before making a final decision as if I go down the plating route it's probably best to send all the bits at once.

Best wishes

Simon

Thanks for your post, it's good to know that there are options, I quite like the plain steel look. I've found a nickel plating place near to where I live but will wait until I get all of the levers and other steel bits before making a final decision as if I go down the plating route it's probably best to send all the bits at once.

Best wishes

Simon

Simon B- Number of posts : 161

Age : 58

Location : Egremont, Cumbria

Registration date : 2014-01-07

Page 4 of 6 •  1, 2, 3, 4, 5, 6

1, 2, 3, 4, 5, 6

Similar topics

Similar topics» 2" Burrel Builders first question!

» New boy on the block!

» introduce myself

» Hi from a New Build

» 1st day of new build

» New boy on the block!

» introduce myself

» Hi from a New Build

» 1st day of new build

Page 4 of 6

Permissions in this forum:

You cannot reply to topics in this forum