4" SCC build so far

+12

Mark the spark

LiveSteam

Steve Traill

Kevster

Ian

chas12154

lynnr

Mick1020

Jim the Shovel

ChriX

TimV

Simon B

16 posters

Page 5 of 6

Page 5 of 6 •  1, 2, 3, 4, 5, 6

1, 2, 3, 4, 5, 6

Re: 4" SCC build so far

Re: 4" SCC build so far

Simon B wrote:Hi Livesteam

Thanks for your post, it's good to know that there are options, I quite like the plain steel look. I've found a nickel plating place near to where I live but will wait until I get all of the levers and other steel bits before making a final decision as if I go down the plating route it's probably best to send all the bits at once.

Best wishes

Simon

My own personal view is that the plain steel look with a bit of burnt steam oil on it gives the engine a more realistic aged look. If I was asked once the other weekend I was asked a dozen times about the age of the agri and the surprised look I got when I said it was 11yrs old was priceless, lots of folks said they thought it was 50yrs or so old

It really is a personal choice as much as the colour choice and how you wish your engine to be viewed, I have a friend who owns a military truck and its far from straight from the factory, it looks like its just returned from a deployment and thats how he likes it and I've heard many folks say its nice to see it in a more realistic state than ones which are sprayed gloss olive drab and then polished to within an inch of their skin, because in real service they just were not like that.

LiveSteam- Number of posts : 788

Location : Hampshire

Registration date : 2013-09-08

4" SCC build so far

4" SCC build so far

Hi All

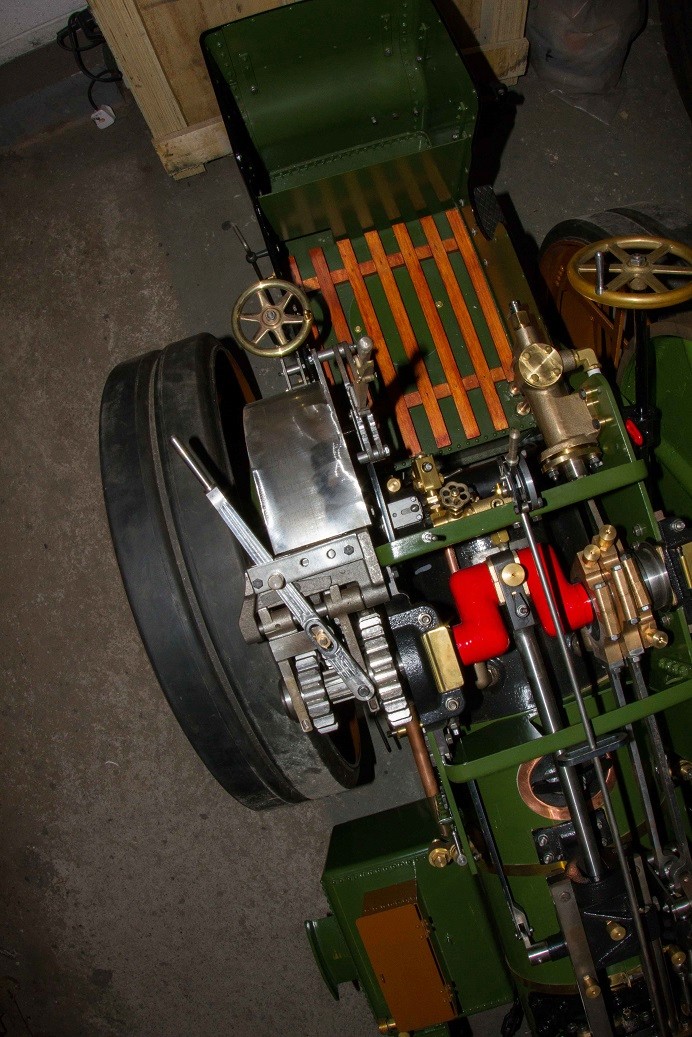

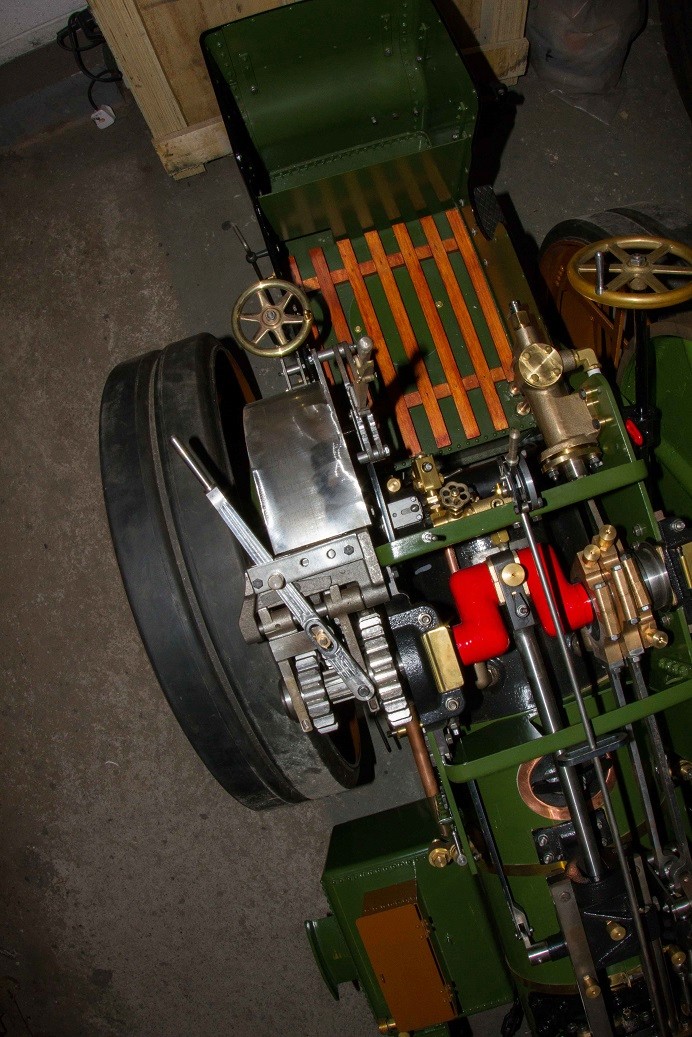

Thought it was about time I posted a build update.

Whistle and governor, these went together easily, The only piece on the governor that needed adjusting was the bottom brass ring that fits over the springs, the centre needed to be opened out by about 0.5mm, now needs a good polish

Levers and fitting, the brake lining was bonded to the strap which then needed to be fed around the rim of the differential and hen he cover fitted over the top, bit of a fiddly job so not looking forward to taking the cover and brake mechanism off to paint. The water pump, steam head water gauge went together really easily. The reversing lever needed a lot of filing to provide clearance for the brass lever to move freely, also the slotted hole in the ratchet locking bar needed to be enlarged to allow the mechanism to move and even to fit the retaining bolt.

The ratchet for the reversing lever was marked out according to the drawing and then filed out, however when fitted when pulled into reverse the lever cannot be pulled back far enough to engage the lock in the rear most slot and when pushed forward the lock overshoots the slot furthest forward. At this stage I'm unsure if this is an issue or not but may well make two new plates and then move the lever to the extents of travel, mark the end slots and then file again. Any advice will be welcome.

Injector clack and reach rod. I wont fit the rest of the copper piping until the injector is delivered.

The gear selector went together easily, with only minimal filing and grinding to give smooth operation of the gears

The rest are various views showing the valve gear, water pump clack and eccentrics.

The next job is to take all of the parts back off, remove the machining marks and then refit.

Only two kits to go now, plus parts that have yet to be delivered from earlier kits. Not long now before I can try the engine on compressed air and then light a fire in it!!

Thought it was about time I posted a build update.

Whistle and governor, these went together easily, The only piece on the governor that needed adjusting was the bottom brass ring that fits over the springs, the centre needed to be opened out by about 0.5mm, now needs a good polish

Levers and fitting, the brake lining was bonded to the strap which then needed to be fed around the rim of the differential and hen he cover fitted over the top, bit of a fiddly job so not looking forward to taking the cover and brake mechanism off to paint. The water pump, steam head water gauge went together really easily. The reversing lever needed a lot of filing to provide clearance for the brass lever to move freely, also the slotted hole in the ratchet locking bar needed to be enlarged to allow the mechanism to move and even to fit the retaining bolt.

The ratchet for the reversing lever was marked out according to the drawing and then filed out, however when fitted when pulled into reverse the lever cannot be pulled back far enough to engage the lock in the rear most slot and when pushed forward the lock overshoots the slot furthest forward. At this stage I'm unsure if this is an issue or not but may well make two new plates and then move the lever to the extents of travel, mark the end slots and then file again. Any advice will be welcome.

Injector clack and reach rod. I wont fit the rest of the copper piping until the injector is delivered.

The gear selector went together easily, with only minimal filing and grinding to give smooth operation of the gears

The rest are various views showing the valve gear, water pump clack and eccentrics.

The next job is to take all of the parts back off, remove the machining marks and then refit.

Only two kits to go now, plus parts that have yet to be delivered from earlier kits. Not long now before I can try the engine on compressed air and then light a fire in it!!

Simon B- Number of posts : 161

Age : 58

Location : Egremont, Cumbria

Registration date : 2014-01-07

Re: 4" SCC build so far

Re: 4" SCC build so far

Nice work Simon, wont be long now !!

TimV- Number of posts : 123

Location : Poole , Dorset

Registration date : 2014-10-09

Re: 4" SCC build so far

Re: 4" SCC build so far

Hi All

Bit of a problem today, I've made gaskets and fitted the safety valves and the valve cover. I've also fitted the water lifter valve and the cylinder drains (what a job they were to make leak tight!!). I then fitted all of the boiler plugs and made a fitting to connect an air line to the plug in the smoke box. I started the compressor and no boiler pressure so I went round to find leaks. Minor leak on the safety valve and the water lifter but no more. Then I put my hand down the chimney, the air is just pouring out through the exhaust.

Has anybody got any ideas on what the problem is and how I can solve it??

Cheers

Simon

Bit of a problem today, I've made gaskets and fitted the safety valves and the valve cover. I've also fitted the water lifter valve and the cylinder drains (what a job they were to make leak tight!!). I then fitted all of the boiler plugs and made a fitting to connect an air line to the plug in the smoke box. I started the compressor and no boiler pressure so I went round to find leaks. Minor leak on the safety valve and the water lifter but no more. Then I put my hand down the chimney, the air is just pouring out through the exhaust.

Has anybody got any ideas on what the problem is and how I can solve it??

Cheers

Simon

Simon B- Number of posts : 161

Age : 58

Location : Egremont, Cumbria

Registration date : 2014-01-07

Re: 4" SCC build so far

Re: 4" SCC build so far

Did you turn the flywheel over to see if the valve seats on its face ,valve might be being held off face for some reason .

Kev

Kev

Kevster- Number of posts : 424

Location : Hertfordshire 4 inch; DCC road loco

Registration date : 2011-01-27

Re: 4" SCC build so far

Re: 4" SCC build so far

As I have said before. Crystal did not want to run on air what so ever. The expansive steam functions so differently. By the sound all that is happening is there is no pressure behind the slide valves so they do not "flap" on to the valve ports and the air just rushes straight out the exhaust port.

Check the valve pucks are ever so slightly loose on the spindles, to allow the flop. To test on air a wee trick is to "glue" the valves on the faces of the ports with steam oil. The oil holds and creates a soft gasket and allows air pressure to build up behind the puck and give you one or two rotations before they flop off again.

Check the valve pucks are ever so slightly loose on the spindles, to allow the flop. To test on air a wee trick is to "glue" the valves on the faces of the ports with steam oil. The oil holds and creates a soft gasket and allows air pressure to build up behind the puck and give you one or two rotations before they flop off again.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: 4" SCC build so far

Re: 4" SCC build so far

Thanks Kev and Lynn

The regulator is closed when air is coming out of the exhaust, when I open the regulator there is a rush of air for about 10 seconds until there is absolutely no pressure in the boiler. Could it be the valve pucks as with the regulator closed there should be no air getting to them, although the regulator could be leaking as well?

Cheers

Simon

The regulator is closed when air is coming out of the exhaust, when I open the regulator there is a rush of air for about 10 seconds until there is absolutely no pressure in the boiler. Could it be the valve pucks as with the regulator closed there should be no air getting to them, although the regulator could be leaking as well?

Cheers

Simon

Simon B- Number of posts : 161

Age : 58

Location : Egremont, Cumbria

Registration date : 2014-01-07

Re: 4" SCC build so far

Re: 4" SCC build so far

Hi

Yes the same principals go for the regulator. Both faces must be flat to the point that a dab of water will stick the puck to the surface.

Again a drop of steam oil under the puck will work for a test.

Yes the same principals go for the regulator. Both faces must be flat to the point that a dab of water will stick the puck to the surface.

Again a drop of steam oil under the puck will work for a test.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: 4" SCC build so far

Re: 4" SCC build so far

Hi Simon, forgive me if I'm am stating the obvious but is your blower valve definitely in the closed position.

Cheers Tim

Cheers Tim

TimV- Number of posts : 123

Location : Poole , Dorset

Registration date : 2014-10-09

Re: 4" SCC build so far

Re: 4" SCC build so far

Hi Lynn and Tim

I'll take the safety valve off tomorrow and put some oil / grease under the regulator and the valve pucks. I haven't got any steam oil yet so grease will hopefully do the trick.

The blower valve is closed, I put my hand down the chimney and jammed my thumb over the end of the exhaust, it was only then that the air pressure in the boiler started to climb.

Cheers

Simon

I'll take the safety valve off tomorrow and put some oil / grease under the regulator and the valve pucks. I haven't got any steam oil yet so grease will hopefully do the trick.

The blower valve is closed, I put my hand down the chimney and jammed my thumb over the end of the exhaust, it was only then that the air pressure in the boiler started to climb.

Cheers

Simon

Simon B- Number of posts : 161

Age : 58

Location : Egremont, Cumbria

Registration date : 2014-01-07

Re: 4" SCC build so far

Re: 4" SCC build so far

Is there any blank pluges under the cylinder? and are they there?

Mark the spark- Number of posts : 389

Location : Edinburgh

Registration date : 2015-04-26

Re: 4" SCC build so far

Re: 4" SCC build so far

Hi Mark

The plugs were both fitted and sealed with foliac before I painted my cylinder block.

Cheers

Simon

The plugs were both fitted and sealed with foliac before I painted my cylinder block.

Cheers

Simon

Simon B- Number of posts : 161

Age : 58

Location : Egremont, Cumbria

Registration date : 2014-01-07

Re: 4" SCC build so far

Re: 4" SCC build so far

Hi All

Now running on air!!

There were two problems, the first was the starter valve, this bypasses the regulator and high pressure side and injects air direct into the low pressure valve chamber therefore no issues with the regulator just a small task to fettle the starter valve. The second problem, as many suggested, was the valve puck being tight on the spindle and not forming a seal. In the end I took a few thou' off the spindle to allow a bit of movement and then about half a mm off the bottom of the actual valve puck, that bit of movement was all that was required to make the engine run.

When I finally managed to get some pressure in the boiler there were a few minor air leaks, all these have been sorted with the exception of the safety valve. With the safety valve in situ, with the amount of air leaking, the maximum boiler pressure was only 30 psi. As the compressor has a safety valve I took the safety valve off the engine and fitted a blanking plate, now <60 psi no problem and plenty of pressure to make it run, although the whistle has now sprung a leak!!

Still all in all it's been a successful day and a joy to see the engine finally running.

Regards

Simon

Now running on air!!

There were two problems, the first was the starter valve, this bypasses the regulator and high pressure side and injects air direct into the low pressure valve chamber therefore no issues with the regulator just a small task to fettle the starter valve. The second problem, as many suggested, was the valve puck being tight on the spindle and not forming a seal. In the end I took a few thou' off the spindle to allow a bit of movement and then about half a mm off the bottom of the actual valve puck, that bit of movement was all that was required to make the engine run.

When I finally managed to get some pressure in the boiler there were a few minor air leaks, all these have been sorted with the exception of the safety valve. With the safety valve in situ, with the amount of air leaking, the maximum boiler pressure was only 30 psi. As the compressor has a safety valve I took the safety valve off the engine and fitted a blanking plate, now <60 psi no problem and plenty of pressure to make it run, although the whistle has now sprung a leak!!

Still all in all it's been a successful day and a joy to see the engine finally running.

Regards

Simon

Simon B- Number of posts : 161

Age : 58

Location : Egremont, Cumbria

Registration date : 2014-01-07

Re: 4" SCC build so far

Re: 4" SCC build so far

Well done Simon, I also had a problem with the safety valves leaking so decieded to take them apart and lap them in, when i steamed the engine for the first time they didnt lift as i just guessed the spring tension but after about 3 steamings or so I have got them to lift at 180 lbs spot on, as you can only adjust them when engine is cold. wont be long before you put a fire in it !! Ive steamed mine 8 times now and today attended my first rally with the Burrell, did about 6 miles on the surrounding lanes and it performed very well.

TimV- Number of posts : 123

Location : Poole , Dorset

Registration date : 2014-10-09

Re: 4" SCC build so far

Re: 4" SCC build so far

Hi Tim

Glad to hear that your engine is now in steam and that you've managed to attend a rally already. I'm still someway off lighting a fire in mine as I'm waiting for the final kit with the lubricator, injector, seat, etc. Hopefully the kit will arrive soon then I can get the engine complete.

Thanks for mentioning your safety valve issues, I was reluctant to take it apart as it's already been set up in the factory, but will follow your lead this week.

Cheers

Simon

Glad to hear that your engine is now in steam and that you've managed to attend a rally already. I'm still someway off lighting a fire in mine as I'm waiting for the final kit with the lubricator, injector, seat, etc. Hopefully the kit will arrive soon then I can get the engine complete.

Thanks for mentioning your safety valve issues, I was reluctant to take it apart as it's already been set up in the factory, but will follow your lead this week.

Cheers

Simon

Simon B- Number of posts : 161

Age : 58

Location : Egremont, Cumbria

Registration date : 2014-01-07

Re: 4" SCC build so far

Re: 4" SCC build so far

Hi Simon, I am waiting for final kit as well but I have supplied my own lubricator , injector and have also made a seat so as I could get on and steam it etc....

Cheers Tim

Cheers Tim

TimV- Number of posts : 123

Location : Poole , Dorset

Registration date : 2014-10-09

Re: 4" SCC build so far

Re: 4" SCC build so far

Hi All

The engine is finally finished, I carried out a test steam on Thursday night which went really well, a few minor leaks. I checked the safety valve functioned correctly, it lifted at 180 PSI and reset at 165PSI, the front one went first, then I held it down and the back one then lifted. All in all a successful night.

My steam test is booked for Monday so today I fixed the leaks and then had another steam, no leaks. The mechanical water pump in bypass is fine and the pipes stay cold, when I came to top up the boiler I turned it to the feed position, I could hear the ball bearing clicking inside the pump and the engine slowed a bit as the pump started to work, the pump got very hot and the engine strained a bit then stopped, the water pump had seized, hopefully it will free off when it cools down, has this happened to anybody else? I haven't got clue how to proceed with the pump other than call HQ on Monday.

I tried to top up the boiler using the injector, turning the water on first and then slowly opening the steam valve, the stream of water running out of the injector turned to a torrent and I'm not sure if any water actually went into the boiler. Again has this happened to others, what am I doing wrong?

In the end I shut the damper, opened the smoke box door and the fire doors to kill the draw and the fire.

I would appreciate any advice on what to do next.

Cheers

Simon

The engine is finally finished, I carried out a test steam on Thursday night which went really well, a few minor leaks. I checked the safety valve functioned correctly, it lifted at 180 PSI and reset at 165PSI, the front one went first, then I held it down and the back one then lifted. All in all a successful night.

My steam test is booked for Monday so today I fixed the leaks and then had another steam, no leaks. The mechanical water pump in bypass is fine and the pipes stay cold, when I came to top up the boiler I turned it to the feed position, I could hear the ball bearing clicking inside the pump and the engine slowed a bit as the pump started to work, the pump got very hot and the engine strained a bit then stopped, the water pump had seized, hopefully it will free off when it cools down, has this happened to anybody else? I haven't got clue how to proceed with the pump other than call HQ on Monday.

I tried to top up the boiler using the injector, turning the water on first and then slowly opening the steam valve, the stream of water running out of the injector turned to a torrent and I'm not sure if any water actually went into the boiler. Again has this happened to others, what am I doing wrong?

In the end I shut the damper, opened the smoke box door and the fire doors to kill the draw and the fire.

I would appreciate any advice on what to do next.

Cheers

Simon

Simon B- Number of posts : 161

Age : 58

Location : Egremont, Cumbria

Registration date : 2014-01-07

Re: 4" SCC build so far

Re: 4" SCC build so far

Make sure all the unions are tight throughout the injector pipe run ,no leaks at all and no blockages either.

Also take the injector off give it a good soak in citric acid,vinegar or any descaler ,there could be some crud in there stopping the injector from working .

hope this helps

Kev

Also take the injector off give it a good soak in citric acid,vinegar or any descaler ,there could be some crud in there stopping the injector from working .

hope this helps

Kev

Kevster- Number of posts : 424

Location : Hertfordshire 4 inch; DCC road loco

Registration date : 2011-01-27

Re: 4" SCC build so far

Re: 4" SCC build so far

Firstly it's unlikely the pump has seized as the tolerance between piston and pump body is taken up by the packing rings and there is quite a bit of clearance. It's more likely the lift in the pump of the balls is insufficient or the clack ball has insufficient lift therefore the water is backing up. Check the clack is fully open as well as I know someone (who shall remain nameless) who turned the pump on with the clack closed and the pump bent the horn plate outwards. Water doesn't compress and it's a strong pump! Also check that the pump is picking up by undo the return pipe & check it's coming out ok. If it's not it's probably a dry joint on the end of the pipe letting air in. Check the silver soldering goes all the way around in a nice shiny collar. If you can't see silver solder all the way around it's a dry joint and could leak air in which stops the pump picking up water.

Regarding the injector, there is a bit of a black art with these, sometimes they work straight out the box as everything else is just right (usually more luck than judgement!) Things to check are the lift on the clack is at least 3mm, the STW injectors pump a lot of water in quite quickly, any restriction just makes them spit the water on the floor. Second ensure there is a good flow of water out of the injector when the water is turned on, drips are no good, a steady flow is what is required. On the Road Loco the water valve I adjusted by drilling out the 3.5mm hole to 5mm to get a better flow. When it comes to using it, turn the water on first and let it cool the injector as sometimes a bit of steam leaks back through the clack & heats up the injector. Injectors only pick up when cold, having a watering can of cold water handy to pour over the injector when you turn it on works sometimes. Turn the water full on, open the steam valve gently and wait to see the injector pick up, it should gurgle & spit a couple of times then pick up. It's a balancing act between just the right amount of water to match the steam. Sometimes it'll pick up but still dribble quite a bit on the floor, turn the water back a little until it's only pumping into the boiler & not the floor! Once it's started sometimes a bit more steam will stop it dribbling on the floor, it's just a matter of getting used to your engine.

Hope this helps

Good luck on Monday.

Regarding the injector, there is a bit of a black art with these, sometimes they work straight out the box as everything else is just right (usually more luck than judgement!) Things to check are the lift on the clack is at least 3mm, the STW injectors pump a lot of water in quite quickly, any restriction just makes them spit the water on the floor. Second ensure there is a good flow of water out of the injector when the water is turned on, drips are no good, a steady flow is what is required. On the Road Loco the water valve I adjusted by drilling out the 3.5mm hole to 5mm to get a better flow. When it comes to using it, turn the water on first and let it cool the injector as sometimes a bit of steam leaks back through the clack & heats up the injector. Injectors only pick up when cold, having a watering can of cold water handy to pour over the injector when you turn it on works sometimes. Turn the water full on, open the steam valve gently and wait to see the injector pick up, it should gurgle & spit a couple of times then pick up. It's a balancing act between just the right amount of water to match the steam. Sometimes it'll pick up but still dribble quite a bit on the floor, turn the water back a little until it's only pumping into the boiler & not the floor! Once it's started sometimes a bit more steam will stop it dribbling on the floor, it's just a matter of getting used to your engine.

Hope this helps

Good luck on Monday.

Steve Traill- Number of posts : 800

Age : 67

Location : Illogan Redruth Cornwall

Registration date : 2008-06-29

Re: 4" SCC build so far

Re: 4" SCC build so far

Simon B wrote:

I tried to top up the boiler using the injector, turning the water on first and then slowly opening the steam valve, the stream of water running out of the injector turned to a torrent and I'm not sure if any water actually went into the boiler. Again has this happened to others, what am I doing wrong?

As others have said, put the water on fully for a few seconds, should get a reasonable stream onto the floor, then unlike others I just wack open the steam valve and 90% of the time she'll pick up, on the odd time it doesnt I shut the steam wait a second or so for it to cool and then turn it back on again, you'll hear it pick up and start gurgling and the water will stop flowing from the drain, if there seems to be quite a dribble from it you can trim it back with the water valve by shutting it down a bit. Go too far and you'll find it will return to a huge amount of steam. If that happens then its start again, shut the steam off, open the water valve fully and then try again with the steam valve.

Personally I find slowly opening the steam valve tends have more pick up failures than just whacking it on.

You may also find it will prefer a certain pressure, mine wont really run below 40psi, also if the water levels above about 2/3rds on the glass it wont pick up as I presume the water level is above the clack valve on the boiler, not that you'll likely need to add water when its that full but at times if you want to drop the pressure quick to stop it blowing off its a handy way, just it wont work when the boilers already pretty full

All the injector connections water side must be completely sealed up, any air getting in and it wont pick up, also the injector will fail with the slightest bit on muck in it. The holes in cones are pretty small, my last issue was due to a tiny bit of ptfe tape that managed to find its way in to it ???

Generally the STW injectors work very very well and really do wind in truck loads of water, its really a case of once you "get the feel" you'll go ahhhhhh thats how it works.

LiveSteam- Number of posts : 788

Location : Hampshire

Registration date : 2013-09-08

Re: 4" SCC build so far

Re: 4" SCC build so far

Hi All

Thanks for your replies, much appreciated.

This afternoon I took the near side clack off to check it was clear and that I'd put the valve handle on the right way round, no problem there. I tried to turn the engine over using the flywheel, no chance, the near side hornplate just flexed, in the end I took the pump off, no small job on a finished engine.

On removing the gland the piston came freely out of the pump but was jammed solidly in the gland, so much so with the pushrod fixed in the vice the brass gland wouldn't even turn and had to hammered off the piston. There is a deep score down the inside of the brass part of the gland but the actual piston is undamaged so using a small fine abrasive wheel I dressed the inside of the brass part, until the piston moved smoothly in the bore, there shouldn't be a problem with removing a bit of metal, as other have said above, it's the gland packing that makes the seal.

I've reassembled the engine and the flywheel now turns smoothly so hopefully when I steam the engine tomorrow it should work.

I've not touched the injector but I'll follow the advice given above, keeping the injector cold seems to be the key. Last night the pipe next to the off side clack was hot, I suppose if the injector is working at all this pipe should cool as water is fed up the pipe and into the boiler?

Once again thank you all for your helpful advice.

Cheers

Simon

Thanks for your replies, much appreciated.

This afternoon I took the near side clack off to check it was clear and that I'd put the valve handle on the right way round, no problem there. I tried to turn the engine over using the flywheel, no chance, the near side hornplate just flexed, in the end I took the pump off, no small job on a finished engine.

On removing the gland the piston came freely out of the pump but was jammed solidly in the gland, so much so with the pushrod fixed in the vice the brass gland wouldn't even turn and had to hammered off the piston. There is a deep score down the inside of the brass part of the gland but the actual piston is undamaged so using a small fine abrasive wheel I dressed the inside of the brass part, until the piston moved smoothly in the bore, there shouldn't be a problem with removing a bit of metal, as other have said above, it's the gland packing that makes the seal.

I've reassembled the engine and the flywheel now turns smoothly so hopefully when I steam the engine tomorrow it should work.

I've not touched the injector but I'll follow the advice given above, keeping the injector cold seems to be the key. Last night the pipe next to the off side clack was hot, I suppose if the injector is working at all this pipe should cool as water is fed up the pipe and into the boiler?

Once again thank you all for your helpful advice.

Cheers

Simon

Simon B- Number of posts : 161

Age : 58

Location : Egremont, Cumbria

Registration date : 2014-01-07

Re: 4" SCC build so far

Re: 4" SCC build so far

Glad you got the pump sorted

The injector clack may not be cool as even though its picking up cold water its bound to be heated by the steam to a good degree, I must admit I've never thought of touching the injector clack to see if its working as you know from the sound its making, where as the pump one is the first port of call when running through my list of stuff to check once I've got enough pressure for her to turn over.

Simon B wrote:

I've not touched the injector but I'll follow the advice given above, keeping the injector cold seems to be the key. Last night the pipe next to the off side clack was hot, I suppose if the injector is working at all this pipe should cool as water is fed up the pipe and into the boiler?

The injector clack may not be cool as even though its picking up cold water its bound to be heated by the steam to a good degree, I must admit I've never thought of touching the injector clack to see if its working as you know from the sound its making, where as the pump one is the first port of call when running through my list of stuff to check once I've got enough pressure for her to turn over.

LiveSteam- Number of posts : 788

Location : Hampshire

Registration date : 2013-09-08

Re: 4" SCC build so far

Re: 4" SCC build so far

Steam test past, no issues during the test and today the mechanical pump worked a treat, although the steam injector wouldn't pick up so I'll take it off and give it a clean over the weekend.

Only one problem today, after half an hours running and after the safety valve test was complete the engine suddenly started on a closed regulator, I checked that the starter valve was closed and even pulled the metal plunger out in the hope that the ball bearing would seat,no chance, a blast of steam came out but a closed regulator only slowed the engine.

In the end I closed the damper, opened the smoke and fire box doors, operated the mechanical pump and waited for the steam pressure to fall with the engine eventually stopping when there was only 30PSI or so left. This is the second time that the starter valve has caused an issue so I think I'm going to blank it off and just palm the flywheel when necessary, the leaky starter valve may also account for the engine 'barking' quite a lot?

Road registration and a seat / trailer next!

Cheers

Simon

Only one problem today, after half an hours running and after the safety valve test was complete the engine suddenly started on a closed regulator, I checked that the starter valve was closed and even pulled the metal plunger out in the hope that the ball bearing would seat,no chance, a blast of steam came out but a closed regulator only slowed the engine.

In the end I closed the damper, opened the smoke and fire box doors, operated the mechanical pump and waited for the steam pressure to fall with the engine eventually stopping when there was only 30PSI or so left. This is the second time that the starter valve has caused an issue so I think I'm going to blank it off and just palm the flywheel when necessary, the leaky starter valve may also account for the engine 'barking' quite a lot?

Road registration and a seat / trailer next!

Cheers

Simon

Simon B- Number of posts : 161

Age : 58

Location : Egremont, Cumbria

Registration date : 2014-01-07

Re: 4" SCC build so far

Re: 4" SCC build so far

Same problem on my DCC. Fitted a stronger spring, problem solved.

Kiwiconnection- Number of posts : 135

Age : 68

Location : Tauranga New Zealand

Registration date : 2011-10-25

Re: 4" SCC build so far

Re: 4" SCC build so far

Hi Phil

Thanks for that, I'm not sure the starter valve gives any real advantage on a single crank so may just block it off with a blank shim, although with all the valve timing and motion fitted it will be a bit of a job to undo the cylinder fixings on the starter valve to remove it, still that's what Saturday mornings were made for 🙂.

Cheers

Simon

Thanks for that, I'm not sure the starter valve gives any real advantage on a single crank so may just block it off with a blank shim, although with all the valve timing and motion fitted it will be a bit of a job to undo the cylinder fixings on the starter valve to remove it, still that's what Saturday mornings were made for 🙂.

Cheers

Simon

Simon B- Number of posts : 161

Age : 58

Location : Egremont, Cumbria

Registration date : 2014-01-07

Page 5 of 6 •  1, 2, 3, 4, 5, 6

1, 2, 3, 4, 5, 6

Similar topics

Similar topics» 2" Burrel Builders first question!

» New boy on the block!

» introduce myself

» Hi from a New Build

» 1st day of new build

» New boy on the block!

» introduce myself

» Hi from a New Build

» 1st day of new build

Page 5 of 6

Permissions in this forum:

You cannot reply to topics in this forum