Today's progress

+9

hudmut

Tony King

IanL

Tim Watson

Kevster

mick 100

Robfishman

lynnr

simonbos

13 posters

Page 2 of 3

Page 2 of 3 •  1, 2, 3

1, 2, 3

More progress

More progress

Have finally been kicked out of wife's utility room and am now completing the build in a makeshift workshop at the farm. Managed to get the boiler painted this weekend - looking forward to bolting other bits on so that it begins to look like a traction engine soon

simonbos- Number of posts : 76

Location : essex

Registration date : 2012-09-20

Lining

Lining

Have now got bits back from being lined. In the end I relented and got Rob Cooper to line them for me and what a wonderful job he has done. I did try to do the lining myself but quickly came to realise that it wasn't a job for me - I would have ruined the engine! Am now busy bolting everything together - will post more photos as I proceed.

simonbos- Number of posts : 76

Location : essex

Registration date : 2012-09-20

Re: Today's progress

Re: Today's progress

Tender bolted to horn plates

simonbos- Number of posts : 76

Location : essex

Registration date : 2012-09-20

Re: Today's progress

Re: Today's progress

Looking very nice and somewhat familiar. It takes courage and strength to say I can not do it and need help to do it well.

Well done Simon.

Well done Simon.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Today's progress

Re: Today's progress

Love the colour scheme, another wonderful engine coming together!!

Regards,

Tony

Regards,

Tony

Tony King- Number of posts : 856

Age : 69

Location : scotland

Registration date : 2008-10-31

Re: Today's progress

Re: Today's progress

Looks wonderful, the great thing about seeing other builds is the great colour combinations. Your lining looks great and I don't blame you for getting someone to do it for you. It's very time consuming and not as easy as it's make to look by those who can.

Today's progress

Today's progress

Hi all

Had a successful day today - now beginning to look like a traction engine. Keep solving one problem only to run into another one. Latest one is the left hand final drive gear/winch pulley hits on the small Allen bolt that holds up the rear of the ash pan which won't allow the sprocket to go on far enough - any ideas how I solve this one? Also how have people fixed the end of the winch rope to the winch drum - I see there is a 6m tapped hole to use - presume I've got to make a small bracket to grip the end of the rope. Any ideas greatly received. Thanks,

Simon

Had a successful day today - now beginning to look like a traction engine. Keep solving one problem only to run into another one. Latest one is the left hand final drive gear/winch pulley hits on the small Allen bolt that holds up the rear of the ash pan which won't allow the sprocket to go on far enough - any ideas how I solve this one? Also how have people fixed the end of the winch rope to the winch drum - I see there is a 6m tapped hole to use - presume I've got to make a small bracket to grip the end of the rope. Any ideas greatly received. Thanks,

Simon

simonbos- Number of posts : 76

Location : essex

Registration date : 2012-09-20

Re: Today's progress

Re: Today's progress

The winch wire can be fitted with a "thimble" then this is held on by a bolt and washer.

Not sure about your problem bolt. How about a picture it may help?

Not sure about your problem bolt. How about a picture it may help?

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Today's progress

Re: Today's progress

Rob

I keep thinking I'm getting near the end but there's still a lot of parts on the bench to fit. There's also a lot of little jobs to tidy up like painting bolt heads/nuts etc.which will all take many hours. Then the real fun will begin when I light a fire in her - I expect there will be steam and water coming from all sorts of places it shouldn't!

Lynn - I'll try and take a photo of the problem bolt tomorrow a.m.

Do I need to put a loop in the copper lubricator pipe than goes from front of lubricator to top of cylinder block? - the pipe looks rather short to get a full coil in. If so I presume its best to coil it around a rod or similar. Thanks again. Simon

I keep thinking I'm getting near the end but there's still a lot of parts on the bench to fit. There's also a lot of little jobs to tidy up like painting bolt heads/nuts etc.which will all take many hours. Then the real fun will begin when I light a fire in her - I expect there will be steam and water coming from all sorts of places it shouldn't!

Lynn - I'll try and take a photo of the problem bolt tomorrow a.m.

Do I need to put a loop in the copper lubricator pipe than goes from front of lubricator to top of cylinder block? - the pipe looks rather short to get a full coil in. If so I presume its best to coil it around a rod or similar. Thanks again. Simon

simonbos- Number of posts : 76

Location : essex

Registration date : 2012-09-20

Re: Today's progress

Re: Today's progress

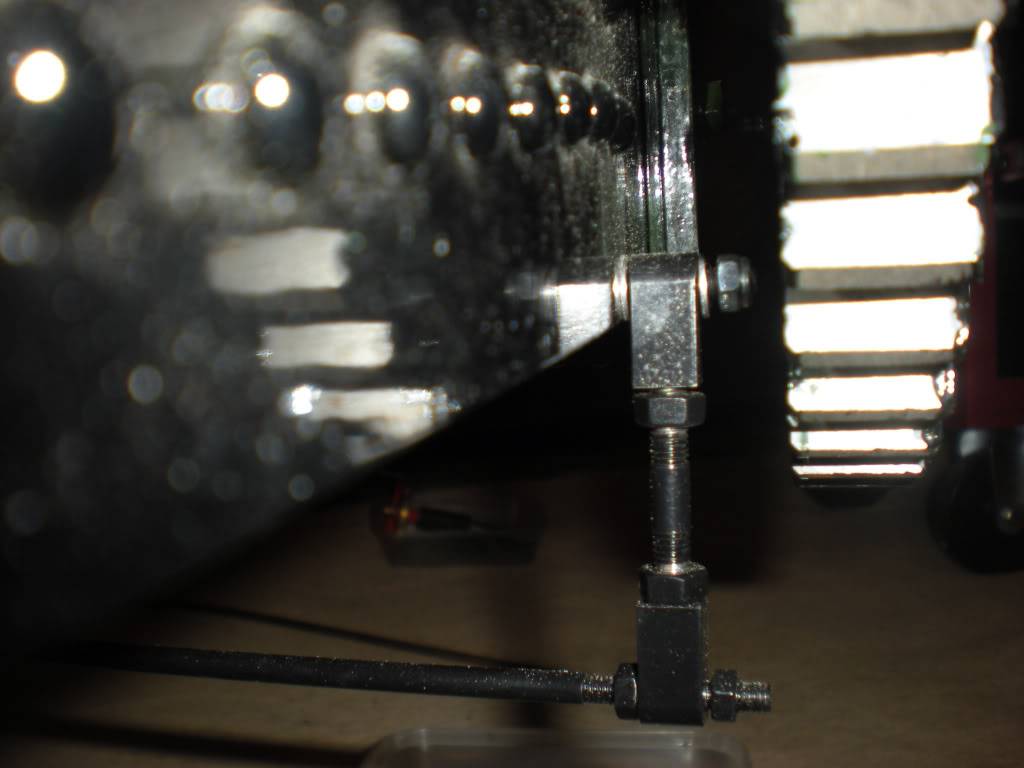

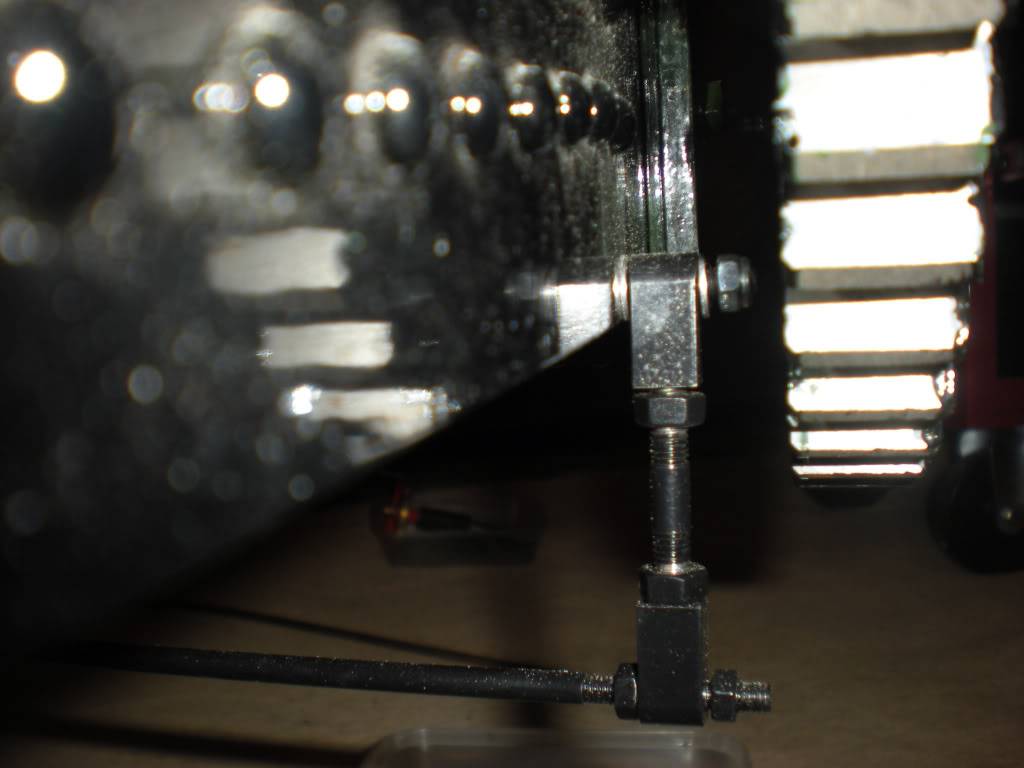

Picture of problem Allen bolt which is in the way of allowing left hand final drive sprocket from going on far enough

Last edited by simonbos on Sun 08 Dec 2013, 12:31 pm; edited 1 time in total (Reason for editing : photo ok - not cropped)

simonbos- Number of posts : 76

Location : essex

Registration date : 2012-09-20

Re: Today's progress

Re: Today's progress

What on earth is that arrangement holding up?? Looks very Heath Robinson to me...  and certainly not right.

and certainly not right.

Re: Today's progress

Re: Today's progress

highpressure

The linkage holds up rear of ashpan. Had a word with Steve today and he suggested using a countersunk allen bolt -easy - problem solved!

The linkage holds up rear of ashpan. Had a word with Steve today and he suggested using a countersunk allen bolt -easy - problem solved!

simonbos- Number of posts : 76

Location : essex

Registration date : 2012-09-20

Re: Today's progress

Re: Today's progress

Your engine is looking splendid simon,

Kev

Kev

Kevster- Number of posts : 424

Location : Hertfordshire 4 inch; DCC road loco

Registration date : 2011-01-27

Re: Today's progress

Re: Today's progress

Hi all

Am now getting to the stage where I want to try running the engine on air - I am keen to sort as many leaks/problems out before I get to lighting a fire. Please could someone tell me how I go about this.

Thanks,

Simon

Am now getting to the stage where I want to try running the engine on air - I am keen to sort as many leaks/problems out before I get to lighting a fire. Please could someone tell me how I go about this.

Thanks,

Simon

simonbos- Number of posts : 76

Location : essex

Registration date : 2012-09-20

Re: Today's progress

Re: Today's progress

Hi Simon

You can run on air for a short while but don't run for too long as the cylinders are not being lubricated by steam oil.

The way I did it was using the "spare" port on the block, I have a siren in it but a standard compressor fitting will also screw in. This will allow pressurization of the complete steam cycle. You may get air leaks where you will not get steam as the system is completely cold and nothing has expanded etc.

Triple check your valve timing and phase so you do not get a piston trying to go forward while the other is trying to go backwards. The valves again will act differently on cold non expanding air over steam. Don't worry too much about precise timing either as yet again the boiler is cold and has not grown in length changing the valve events slightly.

You can do a phased by leaving off the LP chest cover. So it will just vent the air out the side. This will also show any let by in the starter button.

And always before adding pressure. Walk the motion through 2 complete revolutions to confirm all is free and will not bind up.

You can run on air for a short while but don't run for too long as the cylinders are not being lubricated by steam oil.

The way I did it was using the "spare" port on the block, I have a siren in it but a standard compressor fitting will also screw in. This will allow pressurization of the complete steam cycle. You may get air leaks where you will not get steam as the system is completely cold and nothing has expanded etc.

Triple check your valve timing and phase so you do not get a piston trying to go forward while the other is trying to go backwards. The valves again will act differently on cold non expanding air over steam. Don't worry too much about precise timing either as yet again the boiler is cold and has not grown in length changing the valve events slightly.

You can do a phased by leaving off the LP chest cover. So it will just vent the air out the side. This will also show any let by in the starter button.

And always before adding pressure. Walk the motion through 2 complete revolutions to confirm all is free and will not bind up.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Today's progress

Re: Today's progress

Thanks Lynn

My engine is the single cylinder agricultural. There is a threaded hole which looks like 1/4" BSP on the temporary safety valve blanking plate above the regulator - can I attach the airline here?

I have set the timing up as per the instructions.

Thanks,

Simon

My engine is the single cylinder agricultural. There is a threaded hole which looks like 1/4" BSP on the temporary safety valve blanking plate above the regulator - can I attach the airline here?

I have set the timing up as per the instructions.

Thanks,

Simon

simonbos- Number of posts : 76

Location : essex

Registration date : 2012-09-20

Re: Today's progress

Re: Today's progress

That is 1/4" BSP which should be a standard airline fitting. Good luck, its exciting to see it all move for the first time. Then get a fire in it.

Re: Today's progress

Re: Today's progress

Hi all

Today's problem: The glass tube for the water gauge is a bit too long - what is the best thing to cut it with? I tried my dremel with a thin cutting disc but that wouldn't touch it. Also what holds the ashpan pins in place? - am presuming friction as they are a tight fit.

Thanks,

Simon

Today's problem: The glass tube for the water gauge is a bit too long - what is the best thing to cut it with? I tried my dremel with a thin cutting disc but that wouldn't touch it. Also what holds the ashpan pins in place? - am presuming friction as they are a tight fit.

Thanks,

Simon

simonbos- Number of posts : 76

Location : essex

Registration date : 2012-09-20

Re: Today's progress

Re: Today's progress

Simon,

you can get little diamond coated cutting discs for the dremel ,thats what i have used, i think i got them off ebay.

I just scored around the glass then snapped off in a rag

when cutting use some water to keep the dust down I read somewhere the dust can be harmful if breathed in, its a good idea anyway.

hope that helps

Kev

you can get little diamond coated cutting discs for the dremel ,thats what i have used, i think i got them off ebay.

I just scored around the glass then snapped off in a rag

when cutting use some water to keep the dust down I read somewhere the dust can be harmful if breathed in, its a good idea anyway.

hope that helps

Kev

Kevster- Number of posts : 424

Location : Hertfordshire 4 inch; DCC road loco

Registration date : 2011-01-27

Re: Today's progress

Re: Today's progress

hi Simon - you can use a needle file to score a line around the glass then it will snap off cleanly if you file it nice and smoothly

Rickster- Number of posts : 267

Location : canterbury, Kent

Registration date : 2010-02-19

Re: Today's progress

Re: Today's progress

Hi all

Finally got round to running the engine on air this afternoon. Connected up airline - lot of air escaping through injector and some through the whistle. Whistle worked well but decided to take apart to cure leak - put back together to find that it didn't work at all! Still couldn't get the motion to turn by giving the flywheel a push then suddenly occurred to me that it might help if I opened the regulator and hey presto away she went! How stupid can I be! Regulator worked very well. Ticked over like a dream then I saw that the water pump was causing the top corner of the hornplate to flex - something must be out of line. So back to workshop, took off water pump rod, all looked lined up ok but decided to turn it 180 degrees, put back together and what a difference! The engine has had a tight spot since it was assembled which has been niggling me - since turning the pump rod it now turns over without any resistance - am assuming the holes on the rod must be slightly off centre.

Still have to cure injector leak - does anybody have any ideas why this should leak - am reluctant to take apart until I've spoken to Steve as this came as one assembled unit.

I have hit the stainless ball in the whistle gently to see if it seats better - won't know if I've been successful until I try the airline again tomorrow.

Have come home feeling it's been a successful day - it's a great feeling to finally see and hear it all turning over after all these months of assembling bits.

Finally got round to running the engine on air this afternoon. Connected up airline - lot of air escaping through injector and some through the whistle. Whistle worked well but decided to take apart to cure leak - put back together to find that it didn't work at all! Still couldn't get the motion to turn by giving the flywheel a push then suddenly occurred to me that it might help if I opened the regulator and hey presto away she went! How stupid can I be! Regulator worked very well. Ticked over like a dream then I saw that the water pump was causing the top corner of the hornplate to flex - something must be out of line. So back to workshop, took off water pump rod, all looked lined up ok but decided to turn it 180 degrees, put back together and what a difference! The engine has had a tight spot since it was assembled which has been niggling me - since turning the pump rod it now turns over without any resistance - am assuming the holes on the rod must be slightly off centre.

Still have to cure injector leak - does anybody have any ideas why this should leak - am reluctant to take apart until I've spoken to Steve as this came as one assembled unit.

I have hit the stainless ball in the whistle gently to see if it seats better - won't know if I've been successful until I try the airline again tomorrow.

Have come home feeling it's been a successful day - it's a great feeling to finally see and hear it all turning over after all these months of assembling bits.

simonbos- Number of posts : 76

Location : essex

Registration date : 2012-09-20

Re: Today's progress

Re: Today's progress

Exciting times, what a beautiful looking engine.... Very well done!!

Regards,

Tony

Regards,

Tony

Tony King- Number of posts : 856

Age : 69

Location : scotland

Registration date : 2008-10-31

Re: Today's progress

Re: Today's progress

Looking good. If the injector is leaking, it is either through the clack valve on the side of the boiler or through the steam globe valve on the manifold. Both are easy fixes.

HStannard- Number of posts : 58

Location : Rushden, Northants

Registration date : 2011-11-09

Re: Today's progress

Re: Today's progress

Also air leaks are much worse without steam many of these will go if you fill it up and light a fire. I wouldnt be able to hold back at ths point, personally I didnt bother with air just went for straight to steam!!! Even then early leaks will gradually disappear as things seal up as time goes on.

Page 2 of 3 •  1, 2, 3

1, 2, 3

Similar topics

Similar topics» More progress

» Thetford Works (Cornwall)

» 09/10/10 progress

» Lynn Robinson. Showman Scenic

» Presedential Candidate??

» Thetford Works (Cornwall)

» 09/10/10 progress

» Lynn Robinson. Showman Scenic

» Presedential Candidate??

Page 2 of 3

Permissions in this forum:

You cannot reply to topics in this forum