Rickster 4'' RL latest

+18

chop

Steam Traction World

Robfishman

Brian M

Flasback

IanL

Dan

forge

Graeme81

Steve Traill

sonick45

craig@STW

highpressure

bjwlancashire

Kevster

Tony King

lynnr

Rickster

22 posters

Page 4 of 5

Page 4 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Re: Rickster 4'' RL latest

Re: Rickster 4'' RL latest

Rick, I notice your governor pulley is fitted the other way around to Lynn's and hers appears to line up very much better . You mentioned that yours is the way the instructions suggest however fitting it the other way around would improve the belt alignment.

Pleaes note my opinion is worth what you pay for it!

Ian

Pleaes note my opinion is worth what you pay for it!

Ian

IanL- Number of posts : 437

Age : 69

Location : Nottinghamshire

Registration date : 2011-07-25

Re: Rickster 4'' RL latest

Re: Rickster 4'' RL latest

Hi Ian,

Yes you are right, it does improve the alignment but it still needs a gap of about 1/8" between the spindle and the casting on mine to line up like Lynn's does. This must mean the casting is machined incorrectly. Both of which are wrong and it does need to be put right. Also the outer boss of the pulley doesn't line up with the outside diamter of the casting as the hole has been drilled offset. It just all looks wrong.

Hopefully I'll speak to Steve today and see what he advises.

Cheers

Rick

to

Yes you are right, it does improve the alignment but it still needs a gap of about 1/8" between the spindle and the casting on mine to line up like Lynn's does. This must mean the casting is machined incorrectly. Both of which are wrong and it does need to be put right. Also the outer boss of the pulley doesn't line up with the outside diamter of the casting as the hole has been drilled offset. It just all looks wrong.

Hopefully I'll speak to Steve today and see what he advises.

Cheers

Rick

to

Rickster- Number of posts : 267

Location : canterbury, Kent

Registration date : 2010-02-19

Re: Rickster 4'' RL latest

Re: Rickster 4'' RL latest

Hi Rick

You have the governor pulley the wrong way round. The pulley boss should be adjacent to the casting. I have reviewed my instructions and altered them accordingly. They were 'copied and pasted' from the SC which does have the Pulley the otherway round. Appologies for the error. The ISO drawings were however right. If you still have a 3mm misalignment then this could be improved slightly by reducing the overhand of the pulley on the Weighshaft Bracket, either by thinning down the boss of this pulley or better still the casting itself. Assuming the pulley on the other side of the Weighshaft Bracket aligns roughly with the Crank Pulley then the shaft connecting the two Weighshaft Pulleys will need to be altered to suit. The easiest way of doing this would be to carefully counterbore the boss on Weighshaft Pulley with a 10mm drill. You can only gain about 1mm here because of the proximity of the Oiler but it helps a bit. The remainder will need to be taken up with a spacer on the Governor. I'm sure the Governor belt will tolerate some mis-alignment but this needs to be proved in operation.

The drilling of the Governor Base is most unlikely to be wrong. The appearance of ‘off centre’ drilling is caused by variations in the castings. The important thing from an operational view point is that the bevels gears mesh correctly. The same is true for the Bias worm and wheel.

Hope this helps.

Regards

Steve

You have the governor pulley the wrong way round. The pulley boss should be adjacent to the casting. I have reviewed my instructions and altered them accordingly. They were 'copied and pasted' from the SC which does have the Pulley the otherway round. Appologies for the error. The ISO drawings were however right. If you still have a 3mm misalignment then this could be improved slightly by reducing the overhand of the pulley on the Weighshaft Bracket, either by thinning down the boss of this pulley or better still the casting itself. Assuming the pulley on the other side of the Weighshaft Bracket aligns roughly with the Crank Pulley then the shaft connecting the two Weighshaft Pulleys will need to be altered to suit. The easiest way of doing this would be to carefully counterbore the boss on Weighshaft Pulley with a 10mm drill. You can only gain about 1mm here because of the proximity of the Oiler but it helps a bit. The remainder will need to be taken up with a spacer on the Governor. I'm sure the Governor belt will tolerate some mis-alignment but this needs to be proved in operation.

The drilling of the Governor Base is most unlikely to be wrong. The appearance of ‘off centre’ drilling is caused by variations in the castings. The important thing from an operational view point is that the bevels gears mesh correctly. The same is true for the Bias worm and wheel.

Hope this helps.

Regards

Steve

Re: Rickster 4'' RL latest

Re: Rickster 4'' RL latest

Hi Steve,

Thanks for your help. The inner weighshaft pulley does line up with the crank pulley so that's ok. As it seems quite a bit out I think I will have to drill the outside pulley and make a coller to take up the space. The governor casting doesn't seem to be machined with a flat face which is why I thought the recess in the pulley was there to take up any slight irregularity.

cheers

Rick

Thanks for your help. The inner weighshaft pulley does line up with the crank pulley so that's ok. As it seems quite a bit out I think I will have to drill the outside pulley and make a coller to take up the space. The governor casting doesn't seem to be machined with a flat face which is why I thought the recess in the pulley was there to take up any slight irregularity.

cheers

Rick

Rickster- Number of posts : 267

Location : canterbury, Kent

Registration date : 2010-02-19

Re: Rickster 4'' RL latest

Re: Rickster 4'' RL latest

A few more bits done and almost up to date now, and looking forward to tomorrow when the water pump arrives. Seat is now all done - comes from an old potato planter and is very comfy my neighbour managed to soure for me. Allows the legs to go around the tender sides just right. Also picked up a Burrell whistle, although full size, I think it's a bit tall but sounds fab.

Cheers

Rick

https://i.servimg.com/u/f49/15/39/66/26/dcc_rl22.jpg

https://i.servimg.com/u/f49/15/39/66/26/dcc_rl23.jpg

https://i.servimg.com/u/f49/15/39/66/26/dcc_rl24.jpg

https://i.servimg.com/u/f49/15/39/66/26/dcc_rl25.jpg

Cheers

Rick

https://i.servimg.com/u/f49/15/39/66/26/dcc_rl22.jpg

https://i.servimg.com/u/f49/15/39/66/26/dcc_rl23.jpg

https://i.servimg.com/u/f49/15/39/66/26/dcc_rl24.jpg

https://i.servimg.com/u/f49/15/39/66/26/dcc_rl25.jpg

Rickster- Number of posts : 267

Location : canterbury, Kent

Registration date : 2010-02-19

Latest

Latest

Looking very good rick. You had it in steam yet ?

chop- Number of posts : 77

Age : 59

Location : cambs

Registration date : 2010-03-06

Re: Rickster 4'' RL latest

Re: Rickster 4'' RL latest

Hi Mark - Yes I have, twice. I think I was actually the first one to run the engines' motion in steam. After swe spoke, I tried it on air and couldn't keep enough pressure so went to steam the following weekend. There is a short clip on this thread on page 5 I think it is.

Loosened off a bit now and looking forward to running this weekend if I can get the pump on.

You had any thoughts about steaming yours?, after all you were first on air and worked out the timing issue so I thought you would have a go ?.

cheers

Rick

Loosened off a bit now and looking forward to running this weekend if I can get the pump on.

You had any thoughts about steaming yours?, after all you were first on air and worked out the timing issue so I thought you would have a go ?.

cheers

Rick

Rickster- Number of posts : 267

Location : canterbury, Kent

Registration date : 2010-02-19

Latest

Latest

I have had mine in steam 3 times now first time was 7 hours then a couple 4 hours stints all running fine. I won't steam it again now till i have the flywheel. Not sure it will run well with the pump and no flywheel. Injector works great with the mod i did and now have the safety set. Managed to blow the paint off the chimmney so looks like i will have to paint it again.

chop- Number of posts : 77

Age : 59

Location : cambs

Registration date : 2010-03-06

Re: Rickster 4'' RL latest

Re: Rickster 4'' RL latest

Rickster wrote:Seat is now all done - comes from an old potato planter and is very comfy my neighbour managed to soure for me. Allows the legs to go around the tender sides just right.

Rick

Do you have more photos of your seat frame/mounting so I can see how you have fitted yours, it looks high up in the rear photo?

I also have a cast seat to use, it says on it "Burrell Traction Engine" !!!!

Cheers

Brian

bjwlancashire- Number of posts : 938

Location : Mellor, Lancashire

Registration date : 2010-09-07

Re: Rickster 4'' RL latest

Re: Rickster 4'' RL latest

Hi Brian,

There is some earlier photos of the seat fabrication on earlie threads here. The actual seat is a pressed steel one and not cast. I drilled two holes into the top of the seat down into the frame sides The front of the seat rests on the seat frame also so the whole seat is level with the top of the bunker exension.

The only comment I can think of is the smoke from the chimney will blow straight back into my face without any kind of extension. I'll have to see how it goes, but I don't want to run with any kind of extension if at all avoidable. Time will tell.

Cheers

Rick

There is some earlier photos of the seat fabrication on earlie threads here. The actual seat is a pressed steel one and not cast. I drilled two holes into the top of the seat down into the frame sides The front of the seat rests on the seat frame also so the whole seat is level with the top of the bunker exension.

The only comment I can think of is the smoke from the chimney will blow straight back into my face without any kind of extension. I'll have to see how it goes, but I don't want to run with any kind of extension if at all avoidable. Time will tell.

Cheers

Rick

Rickster- Number of posts : 267

Location : canterbury, Kent

Registration date : 2010-02-19

Re: Rickster 4'' RL latest

Re: Rickster 4'' RL latest

Here is a short video clip of a run down the road after the steam test

Rickster- Number of posts : 267

Location : canterbury, Kent

Registration date : 2010-02-19

Re: Rickster 4'' RL latest

Re: Rickster 4'' RL latest

This time with the link !

https://www.youtube.com/channel/UCk80xJBH_kfZh8_U_bV1oIg?feature=plcp

I'm not very good with this you tube lark, as you can see!

cheers

Rick

https://www.youtube.com/channel/UCk80xJBH_kfZh8_U_bV1oIg?feature=plcp

I'm not very good with this you tube lark, as you can see!

cheers

Rick

Rickster- Number of posts : 267

Location : canterbury, Kent

Registration date : 2010-02-19

Re: Rickster 4'' RL latest

Re: Rickster 4'' RL latest

Well done. Looking good. See the weather is dry and sunny.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Rickster 4'' RL latest

Re: Rickster 4'' RL latest

It's really great to these engines come to life life this. Well done on another cracking engine Rick.

Re: Rickster 4'' RL latest

Re: Rickster 4'' RL latest

looking good

Richard- Number of posts : 105

Location : sway hampshire

Registration date : 2011-09-08

Re: Rickster 4'' RL latest

Re: Rickster 4'' RL latest

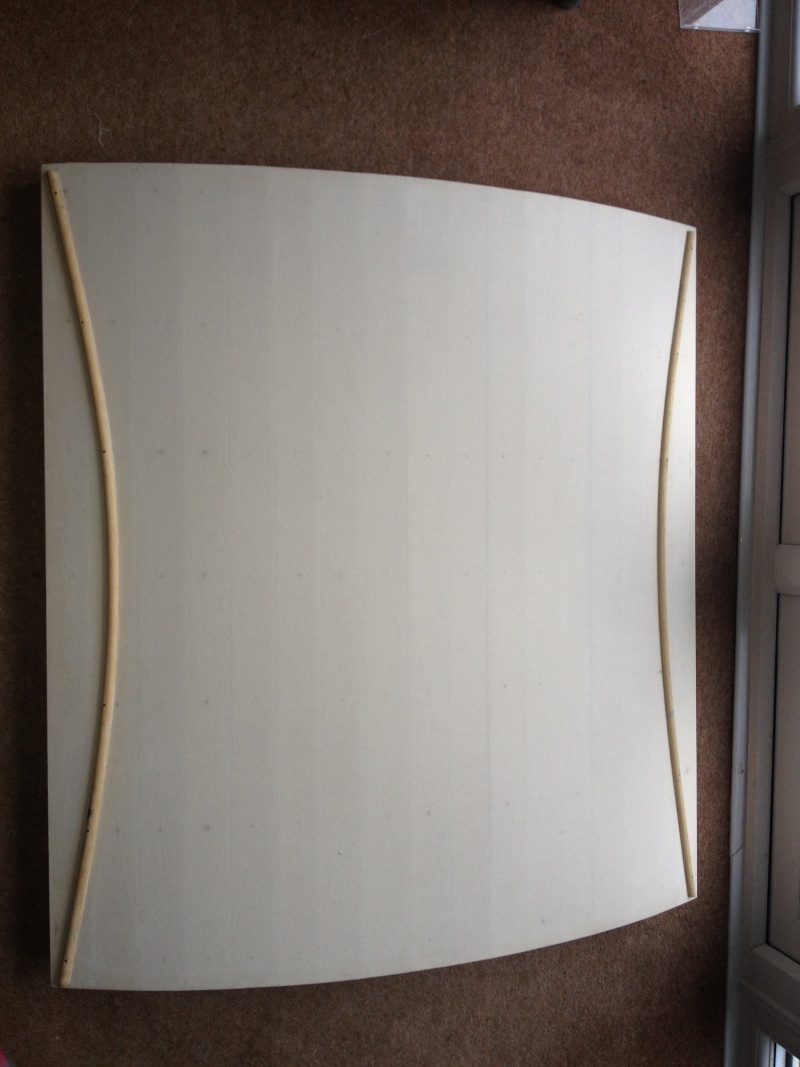

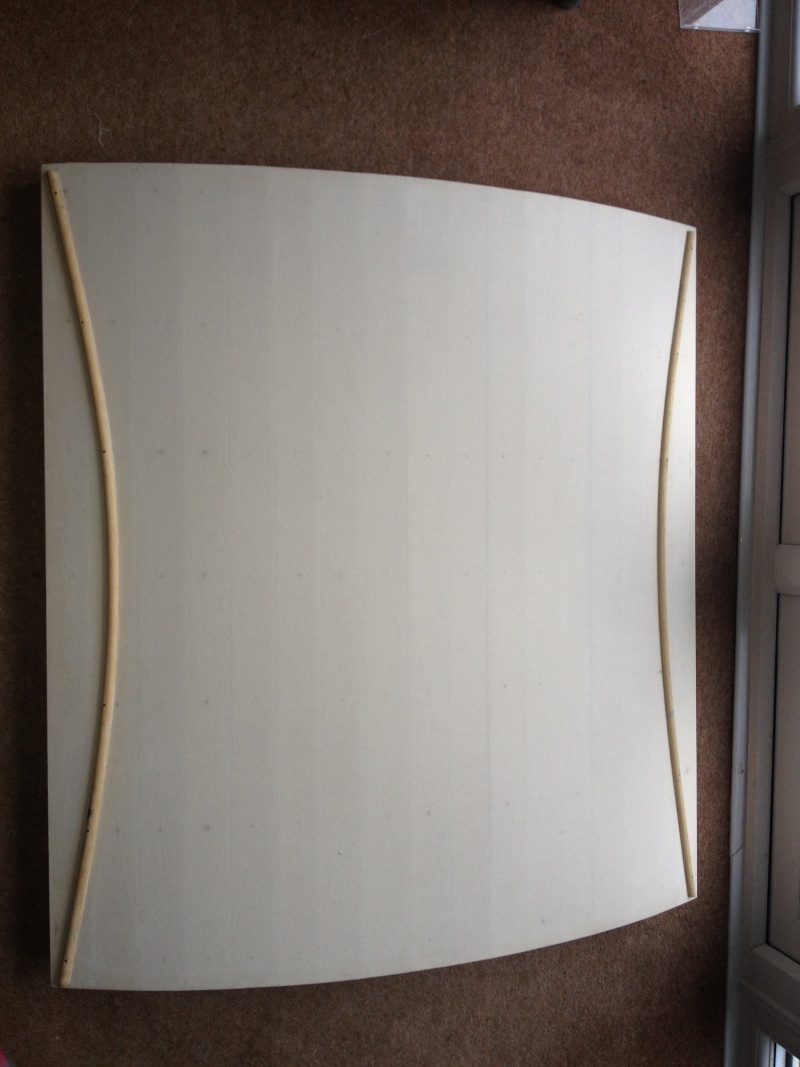

A few update pics post Xmas for everyone. Finally sorted out the lubricator problem - the ball bearing was the wrong size, a new one sent out in two days and it now pumps so hopefully today will be anothe exuse for a steam test!

The roof is now finished:

And on the engine, with just the fitting and painting to do.

Just the motion covers to paint then after this then it's job done. I'm going to attempt the signwriting on the roof myself - should be ineteresting! over the winter as it's not going to be on the engine when running, so plenty of time to take it slowly.

cheers

Rick

The roof is now finished:

And on the engine, with just the fitting and painting to do.

Just the motion covers to paint then after this then it's job done. I'm going to attempt the signwriting on the roof myself - should be ineteresting! over the winter as it's not going to be on the engine when running, so plenty of time to take it slowly.

cheers

Rick

Rickster- Number of posts : 267

Location : canterbury, Kent

Registration date : 2010-02-19

Re: Rickster 4'' RL latest

Re: Rickster 4'' RL latest

Looking excellent Rick.

Nice seeing these engines coming to completion and alive. When do you plan to have your steam inspection?

I am very jelous that the road loco's got their roofs. Would have been nice to have something to potter with over the Xmas period to keep me from going mad.

So congratulations on your build. When will we get a picture fully complete?

Nice seeing these engines coming to completion and alive. When do you plan to have your steam inspection?

I am very jelous that the road loco's got their roofs. Would have been nice to have something to potter with over the Xmas period to keep me from going mad.

So congratulations on your build. When will we get a picture fully complete?

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Rickster 4'' RL latest

Re: Rickster 4'' RL latest

That's another very "individual" looking engine, Rick. Love the cast iron seat you've grafted onto the back. You must be delighted & very proud to have built a such superp engine.

I think the roof kits really finish off these engines, I know that the "practicality" of running them may be effected, but to my mind well worth it in "WOW" factor!!

Like Lynn, I can hardly wait to see how STW are coming along with the Showmans roof kits When they go out, you Road Loco guys are going to get a run for your money

When they go out, you Road Loco guys are going to get a run for your money

Well done & keep the pics coming,

Regards,

Tony

I think the roof kits really finish off these engines, I know that the "practicality" of running them may be effected, but to my mind well worth it in "WOW" factor!!

Like Lynn, I can hardly wait to see how STW are coming along with the Showmans roof kits

Well done & keep the pics coming,

Regards,

Tony

Tony King- Number of posts : 856

Age : 69

Location : scotland

Registration date : 2008-10-31

Ricksters 4" rl latest

Ricksters 4" rl latest

Very nice and well done, merry Xmas and happy new year to u

tractor mike- Number of posts : 74

Age : 40

Location : taunton somerset

Registration date : 2012-01-29

Re: Rickster 4'' RL latest

Re: Rickster 4'' RL latest

looks great Rick, what size whistle do you have on the engine and how does it sound, looks the dogs, is it a full size or 6" as I was looking at going one for the showman engine?

cheers Dwain

cheers Dwain

Flasback- Number of posts : 191

Location : Cheshire

Registration date : 2011-01-30

Re: Rickster 4'' RL latest

Re: Rickster 4'' RL latest

Looks good Rick, the roof posts dont seem to be all the way in to the holders in the tender, I thought they went right in till the blob for the diagonals touches??

Lynn, Rick had his tests done in October I believe all legal!!!

Lynn, Rick had his tests done in October I believe all legal!!!

Re: Rickster 4'' RL latest

Re: Rickster 4'' RL latest

yes Kev's right - all legal since October.

The whistle is a full size - people definately know when I'm around the corner!

Kev, the bolts for the roof supports were blocking the holes when I had tightened them up so just need to shorten the threads.

The seat is not actually a cast iron one - my neighbour works for a farmer and got me this one from a 30's potato planter. It's actually bang on because it's designed to work with your legs spread and so works nicely around the tender.

The lubricator is now 100% - I was steaming for 6 hours and used almost a full tank of oil .

.

question for you Kev or anyone else for that matter - I'm finding I have to keep the blower on when on the road to keep a good fire and wondered if you do the same ? I would have thought it should pull the fire up with the engine working. It maybe my lack of experience but would be good to know. I'm using a mixture of anthracite with house coal and when on the road the coal is about fire hole door height and I can hear the fire roaring away. When above 120 psi it picks up quickly to over 150 within about 5 minutes even after injecting a lot of water with the blower on.

I was wondering whether to modify the blast pipe to pull the fire up, after I can always close the damper and it would be nice to have an easier steamer. As i say it may well be just me, so any advice would be welcome.

Steve, you will be pleased to know the modified stem for the injector steam valve works perfectly! so easy and no pressure at all needed on the wheel to shut off the steam.

cheers

Rick

The whistle is a full size - people definately know when I'm around the corner!

Kev, the bolts for the roof supports were blocking the holes when I had tightened them up so just need to shorten the threads.

The seat is not actually a cast iron one - my neighbour works for a farmer and got me this one from a 30's potato planter. It's actually bang on because it's designed to work with your legs spread and so works nicely around the tender.

The lubricator is now 100% - I was steaming for 6 hours and used almost a full tank of oil

question for you Kev or anyone else for that matter - I'm finding I have to keep the blower on when on the road to keep a good fire and wondered if you do the same ? I would have thought it should pull the fire up with the engine working. It maybe my lack of experience but would be good to know. I'm using a mixture of anthracite with house coal and when on the road the coal is about fire hole door height and I can hear the fire roaring away. When above 120 psi it picks up quickly to over 150 within about 5 minutes even after injecting a lot of water with the blower on.

I was wondering whether to modify the blast pipe to pull the fire up, after I can always close the damper and it would be nice to have an easier steamer. As i say it may well be just me, so any advice would be welcome.

Steve, you will be pleased to know the modified stem for the injector steam valve works perfectly! so easy and no pressure at all needed on the wheel to shut off the steam.

cheers

Rick

Rickster- Number of posts : 267

Location : canterbury, Kent

Registration date : 2010-02-19

Re: Rickster 4'' RL latest

Re: Rickster 4'' RL latest

Rick

I would think your coal mixture may account for your firing problems. I have heard it said that mixtures of coal are not good in a steam engine. Kev's engine certainly knows how to boil water running on Welsh steam ooal!

A very elegant engine!

Tim

I would think your coal mixture may account for your firing problems. I have heard it said that mixtures of coal are not good in a steam engine. Kev's engine certainly knows how to boil water running on Welsh steam ooal!

A very elegant engine!

Tim

Tim Watson- Number of posts : 585

Location : Herts

Registration date : 2008-07-02

Re: Rickster 4'' RL latest

Re: Rickster 4'' RL latest

Hi Kevin

I have no problem steaming on plain old premier house coal. Even down at a thin bed. When I took Crystal out for the first time I actually ran out of fire. My fault completely. Down to 50 psi. Reset a fire. Blower on 1/2 and she was back in 2 mins. With a fire about 1/2 way up to the door gave plenty fire with blower off. She held 150-175.

I have also heard mixing to not work very well and anthracite does need a lot more care and initial

heat. You could also have too thick a bed and chocking. As well as not having room for the gases to combust fully.

I have no problem steaming on plain old premier house coal. Even down at a thin bed. When I took Crystal out for the first time I actually ran out of fire. My fault completely. Down to 50 psi. Reset a fire. Blower on 1/2 and she was back in 2 mins. With a fire about 1/2 way up to the door gave plenty fire with blower off. She held 150-175.

I have also heard mixing to not work very well and anthracite does need a lot more care and initial

heat. You could also have too thick a bed and chocking. As well as not having room for the gases to combust fully.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Rickster 4'' RL latest

Re: Rickster 4'' RL latest

thanks both for your comments. I start on house coal because it is so easy to catch at an early stage to begin builidng the fire. Anthracite needs much more heat to burn so I switch over, bit like the old Fordson tractors starting on petrol then turning to paraffin when they get hot.

I then mostly on antrachite unless the fire goes too far down. I think Steve mentions anthrcite in the steaming instructions - very hot but it then dissappears very quickly.

I will have another go tomorrow and see if i keep to 150 without using the blower by just running g the engine around.

I assume to should hold this with the engine working without too much trouble ?

thanks for your help guys and gals

Rick

I then mostly on antrachite unless the fire goes too far down. I think Steve mentions anthrcite in the steaming instructions - very hot but it then dissappears very quickly.

I will have another go tomorrow and see if i keep to 150 without using the blower by just running g the engine around.

I assume to should hold this with the engine working without too much trouble ?

thanks for your help guys and gals

Rick

Rickster- Number of posts : 267

Location : canterbury, Kent

Registration date : 2010-02-19

Page 4 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Similar topics

Similar topics» Latest News on DCC

» final assembly started 040510

» Thetford Works (Cornwall)

» Presedential Candidate??

» Latest News 16/07/2008

» final assembly started 040510

» Thetford Works (Cornwall)

» Presedential Candidate??

» Latest News 16/07/2008

Page 4 of 5

Permissions in this forum:

You cannot reply to topics in this forum