Steaming again!!

+13

craig@STW

IanL

Tony King

Steve Traill

Steam Traction World

lynnr

sonick45

Tim Watson

Kiwiconnection

bjwlancashire

Rickster

Dan

highpressure

17 posters

Page 1 of 3

Page 1 of 3 • 1, 2, 3

Steaming again!!

Steaming again!!

Having got the cold test done and using the rest of Sunday to fit the last kit on the engine I have been waiting for four days for the rain to give up so I can get a head of steam up and test all the components so far. So this morning got set up and lit the fire, lots of condensation as before making it hard work to really get going but eventually heard the familar sound of the blower. Good to see the gauge work, but the phrase a watched kettle etc is so true, it took forever to get to even 30 psi. Then tried the water pump.... sadly I hadn't noticed a manufacturing defect on the mating face of the bypass as water shot out as soon as I tried to put it in the boiler. Had to take it off and apart to correct it, the face on the pump body looked like the balls on the govenor as in it had a strip across the middle. Spoke to Steve and to be honest can't be arsed to send it back so took a file to it and got it almost flat and then used some gasket paper and its fine now. Couldn't get the injector to work but after speaking to Steve it needs at least 70 on the clock before it will pick up and I only just got to 60 or so before giving up. Had various leaks which I made a note of but was really bothered by an unusal amount of water running down the back of the belly tank. Thought I was going to have to take it off but it turned out to be the drain in the cylinder LP exhaust leaking water which ran inside the cleading and came out there. By then I was pretty despondant so gave up and dropped the fire.

After a bit of lunch and having sorted out the pump and re-sealed the various fittings I thought I would have another go this afternoon. This time it was much better as in I went for it with the fire and had steam feeding the blower in about 30 minutes. Got up to 100psi and tried the injector. This time it picked up and ran until the pressure was down to about 60. The pump worked fine but then highlighted another manufacturing issue... virtually no solder on the union at the top joint. Luckily father in law is a plumber and he was able to run the blowtorch on it and sort. Obviously not my lucky kit!!!!

Ran the crank for some time and highlighted a few more issues. Firstly all other RL builders be warned the oiler for the water pump needs to be RIGHT and TIGHT. Mine wasn't and has taken a good lump out of the paint, but was my fault not checking it was right before running.

Simpling Valve: currently is acting as a double high as the engine runs like mad with the valve rod back but if you push it in casuing the stem of the valve to enter the cylinder block slowing the steam down it slows the engine down and it can be stopped. This is not how it should be, the valve should seat on the ball and pushing the rod opens it briefly giving a squirt of high pressure into the low cylinder, clearly I need to get a better seat on the ball union point.

BEWARE

BEWARE  if your engine has this condition it can start turning without warning if in forward or reverse. If your fingers or hands are anywhere near moving parts IT WILL TAKE THEM OFF!!!!! WATCH OUT

if your engine has this condition it can start turning without warning if in forward or reverse. If your fingers or hands are anywhere near moving parts IT WILL TAKE THEM OFF!!!!! WATCH OUT

It is very difficult to check this without being in steam, dont assume you have the valve right first time. Also because it is taken off the regulator chest before the regulator itself it is not able to be controlled and consequently as the pressure builds it can cause the LP cylinder to work regardless.

It is very difficult to check this without being in steam, dont assume you have the valve right first time. Also because it is taken off the regulator chest before the regulator itself it is not able to be controlled and consequently as the pressure builds it can cause the LP cylinder to work regardless.

Whislte STILL leaks like a bitch having messed about with it three times!!!! So I will try again.

GIVE UP keeping it clean, crap is everywhere now, no chance of getting to some of it and anyway as soon as its clean it will be dirty 20 minutes after starting..

Anyone else having a go a steaming now we have all the bits?? would be interested to know if I am the only one going throught these teething troubles, can't imagine I am. As Steve Trail said the list gets made and gets shorter each time its in steam, only a few little niggles left but would be much easier with a flywheel. Going to be really tight to actually get it into steam at any do's this year though But I am still holding out hope.

But I am still holding out hope.

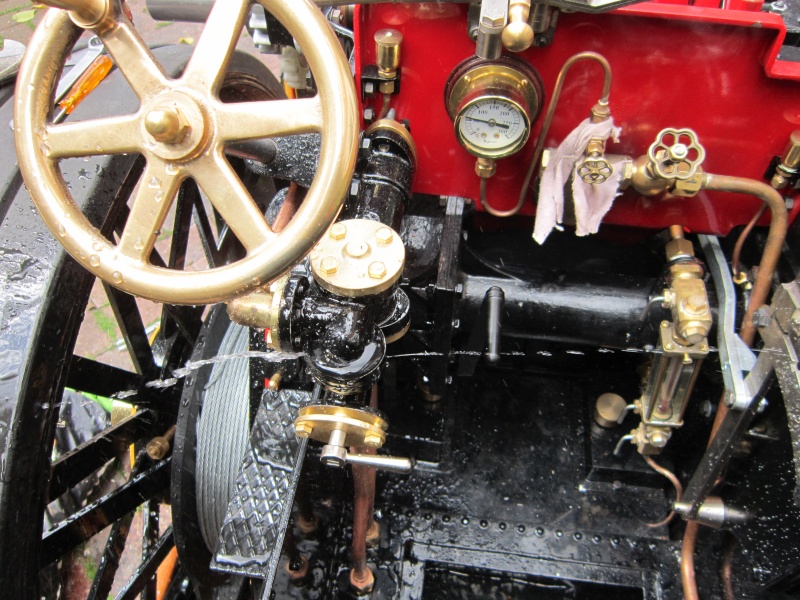

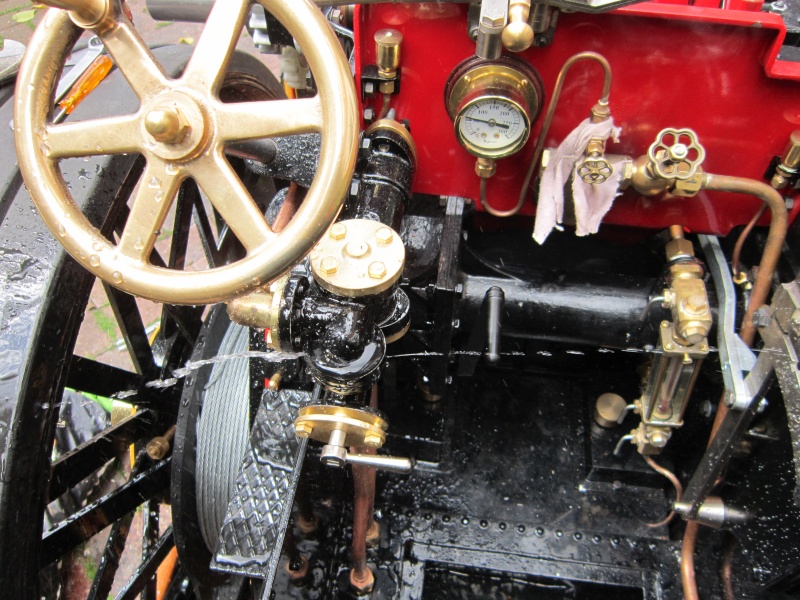

First signs of life!!

Reassuring to finally see what is going on!

Water going everywhere but where it should!!

After a bit of lunch and having sorted out the pump and re-sealed the various fittings I thought I would have another go this afternoon. This time it was much better as in I went for it with the fire and had steam feeding the blower in about 30 minutes. Got up to 100psi and tried the injector. This time it picked up and ran until the pressure was down to about 60. The pump worked fine but then highlighted another manufacturing issue... virtually no solder on the union at the top joint. Luckily father in law is a plumber and he was able to run the blowtorch on it and sort. Obviously not my lucky kit!!!!

Ran the crank for some time and highlighted a few more issues. Firstly all other RL builders be warned the oiler for the water pump needs to be RIGHT and TIGHT. Mine wasn't and has taken a good lump out of the paint, but was my fault not checking it was right before running.

Simpling Valve: currently is acting as a double high as the engine runs like mad with the valve rod back but if you push it in casuing the stem of the valve to enter the cylinder block slowing the steam down it slows the engine down and it can be stopped. This is not how it should be, the valve should seat on the ball and pushing the rod opens it briefly giving a squirt of high pressure into the low cylinder, clearly I need to get a better seat on the ball union point.

It is very difficult to check this without being in steam, dont assume you have the valve right first time. Also because it is taken off the regulator chest before the regulator itself it is not able to be controlled and consequently as the pressure builds it can cause the LP cylinder to work regardless.

It is very difficult to check this without being in steam, dont assume you have the valve right first time. Also because it is taken off the regulator chest before the regulator itself it is not able to be controlled and consequently as the pressure builds it can cause the LP cylinder to work regardless. Whislte STILL leaks like a bitch having messed about with it three times!!!! So I will try again.

GIVE UP keeping it clean, crap is everywhere now, no chance of getting to some of it and anyway as soon as its clean it will be dirty 20 minutes after starting..

Anyone else having a go a steaming now we have all the bits?? would be interested to know if I am the only one going throught these teething troubles, can't imagine I am. As Steve Trail said the list gets made and gets shorter each time its in steam, only a few little niggles left but would be much easier with a flywheel. Going to be really tight to actually get it into steam at any do's this year though

First signs of life!!

Reassuring to finally see what is going on!

Water going everywhere but where it should!!

Re: Steaming again!!

Re: Steaming again!!

Like the last action shot!!!!

Have you got the steam blower on all the time? I only use mine when I have ~30psi minimum really.

Have you got the steam blower on all the time? I only use mine when I have ~30psi minimum really.

Dan- Number of posts : 138

Age : 50

Location : East Anglia

Registration date : 2011-09-07

Re: Steaming again!!

Re: Steaming again!!

No, I only use the blower to get the initial head of steam or if I am not running and need to get the fire up, without the flywheel running is quite painful still. Will have to do the hot test when the flywheel is here which needs the blower on full bore with a deep fire to check the safeties open and don't go over 10%, it's quite a scary thing to watch but having done them on other engines it's something I'm used to.

Clearly the answer here is no!!

Anyone else having a go a steaming now we have all the bits?? would be interested to know if I am the only one going throught these teething troubles, can't imagine I am

Clearly the answer here is no!!

Re: Steaming again!!

Re: Steaming again!!

Hi Kev,

Probably everyone waiting for the fix on the water pump oiler before steaming again.

I spent today trying something different as I wasn't too keen on what Steve has done for a solution to the problem, as you can see it needs a bit of refining but I'm ok with the idea.

Got the replacement front drain pipe from Isobel the day after I rang - fantastic service. They're all done now and much better for the longer front pipe I think.

I haven't had or should I say didn't notice any problem with the mating surface on the water pump. It's all sealed up, painted and fitted now so tomorrow, Kids permitting, I will steam and let you know how I got on.

Finally finished the seat and I have to say it really is very comfy back there. Time will tell how I get on with the smoke blowing in my face when on the move.

Getting used to taking the water pump drive eccentrics on and off now - only takes about an hour now!

Best way to get to the bottom nut I found is to put two nuts in a 10mm 1/4 drive socket. Hold the first one in with blu tak and then it go as per Steve's instructions. No lost nuts and very easy to do.

Cheers

Rick

Probably everyone waiting for the fix on the water pump oiler before steaming again.

I spent today trying something different as I wasn't too keen on what Steve has done for a solution to the problem, as you can see it needs a bit of refining but I'm ok with the idea.

Got the replacement front drain pipe from Isobel the day after I rang - fantastic service. They're all done now and much better for the longer front pipe I think.

I haven't had or should I say didn't notice any problem with the mating surface on the water pump. It's all sealed up, painted and fitted now so tomorrow, Kids permitting, I will steam and let you know how I got on.

Finally finished the seat and I have to say it really is very comfy back there. Time will tell how I get on with the smoke blowing in my face when on the move.

Getting used to taking the water pump drive eccentrics on and off now - only takes about an hour now!

Best way to get to the bottom nut I found is to put two nuts in a 10mm 1/4 drive socket. Hold the first one in with blu tak and then it go as per Steve's instructions. No lost nuts and very easy to do.

Cheers

Rick

Rickster- Number of posts : 267

Location : canterbury, Kent

Registration date : 2010-02-19

Re: Steaming again!!

Re: Steaming again!!

That's a neat idea Rick, passed the test with that one.

How about the bracket being trapped at the rear behind the clamping bolt head too, only a short pipe then too? Or is there a chance of fouling somewhere.

Great post though, made me think how to refine it some more which is what this is all about.

Brian

How about the bracket being trapped at the rear behind the clamping bolt head too, only a short pipe then too? Or is there a chance of fouling somewhere.

Great post though, made me think how to refine it some more which is what this is all about.

Brian

bjwlancashire- Number of posts : 938

Location : Mellor, Lancashire

Registration date : 2010-09-07

Re: Steaming again!!

Re: Steaming again!!

Hi Rick,

Interesting idea for the oiler, perhaps its a bit too tall now, I think the idea for the long one is to save having to get to it too often and a shorter one would be a sod to open but as yours is more accessible it might warrant a short one now. Would like to see a picture of the seat as I'm considering my options but might still wait for the STW choice as making something will need various pieces of steel and I don't have access to odd bits. With all the cancelled rallies now I have kind of lost my mojo to get going although the forecast is changing for the short term which might re-ignite me

Would be interested to see what you think of the starting valve issue, watch out for it especially as you get to 80+ psi. Let me know if you find anything there.

Cheers Kev.

Interesting idea for the oiler, perhaps its a bit too tall now, I think the idea for the long one is to save having to get to it too often and a shorter one would be a sod to open but as yours is more accessible it might warrant a short one now. Would like to see a picture of the seat as I'm considering my options but might still wait for the STW choice as making something will need various pieces of steel and I don't have access to odd bits. With all the cancelled rallies now I have kind of lost my mojo to get going although the forecast is changing for the short term which might re-ignite me

Would be interested to see what you think of the starting valve issue, watch out for it especially as you get to 80+ psi. Let me know if you find anything there.

Cheers Kev.

Re: Steaming again!!

Re: Steaming again!!

I had tried that first but then to tighten it up sufficiently caused to much compression on the ecccentric straps and locked the drive solid. I could have then got into shimming the strap but thought this was easier.

I do need to shorten the bracket a bit though, but I think I will stick with this principle and just refine it a bit particularly with the bottom of the bracket to make it fit snug on the flat of the eccentric strap so it can't move if the nut comes loose.

cheers

Rick

I do need to shorten the bracket a bit though, but I think I will stick with this principle and just refine it a bit particularly with the bottom of the bracket to make it fit snug on the flat of the eccentric strap so it can't move if the nut comes loose.

cheers

Rick

Rickster- Number of posts : 267

Location : canterbury, Kent

Registration date : 2010-02-19

Re: Steaming again!!

Re: Steaming again!!

Looking at the problem with the oiler for the pump drive. I think I would just machine a new oil hole in the other strap and then plug the origional hole....... job done.

Kiwiconnection- Number of posts : 135

Age : 68

Location : Tauranga New Zealand

Registration date : 2011-10-25

Re: Steaming again!!

Re: Steaming again!!

May not be that easy because of the top stud for the pump rod in the oil hole path. Simple solution is to make a showman, although I don't think that is too helpful to some of our brethren on this thread. If you increase the oil hole size slightly and modify the tip of your oiler to fit, there is no need to keep unscrewing the cap to oil up.

How's this lubricator done on President?

Tim

How's this lubricator done on President?

Tim

Tim Watson- Number of posts : 585

Location : Herts

Registration date : 2008-07-02

Re: Steaming again!!

Re: Steaming again!!

don't look like the president has one however this photo isn't the clearest.

[img] [/img]

[/img]

[img]

[/img]

[/img]

sonick45- Number of posts : 511

Location : Barton-Le-Clay (Beds)

Registration date : 2009-01-26

Re: Steaming again!!

Re: Steaming again!!

Managed to steam again today from 10 till 5 this evening. Took ages to get a reading on the clock - no wind at all to help.

with 50 on the clock and blower on, soon got to 70. Starting to get a feel for putting water in balancing it with a decent fire to maintain the heat when the injector takes the steam.

I was quite surprised how much steam the injector uses. It worked superbly - anything over 70 psi is fine all the way up to 180 when the safeties blew off.

The water lifter was also brilliant and doesn't use much steam up. Empies a two gallon watering can in about a minute - it's amazing.

I have had five main problems through the day -

1. Both unions on the water pump lead like a sieve and I couldn't get any water into the boiler with the pump at all. No other leaks from the pump but I have a leak from the union into the water tank at the tender top.

The clack valve was constantly hot but the delivery pipe was cold. It looked like a pretty major leak but I'm ot experienced in these things to tell if any was going in so I concentrated on the injector, which never failed to pick up. At one one point it was picking up down to just over 50 on the clock.

2. Same problem as Highpressure with the starting valve. Not sure whats going on but it does seem that the valve is not always shutting. When the engine stalls it sometimes started of it's own accord if the reverser was full forward or reverse.

3. I struggled with the lubricator all day. Steam or air was blowing by the one way valve as bubbles were appearing in the oil box. I loosened off the pipe to the one way and could feel it pressurise. Put it back on but still the oil level was not going down in the box. I ended up squirting oil in through the non return valve manually.

Anyone any ideas as to what could be wrong. Maybe not enough pumping pressure and a leaky non return valve ??

4. The steam valve for the injector does not have a good steam tight seal. I had to really close it hard with the aid of a pair of pliers. As the pressure increased I then couldn't open the valve which casued a bit of concern as I was dow to 1/4 glass. I took the wheel off and put a nut either side of it so I could get a spanner on it to aid opening and closing. It shouldn't be like this and I will speak to Steve as this is the second one I've had a problem with.

5. Again as per Highpressure - the whistle valve continues to leak like a sieve.

Oh yeah - and the oiler for the water pump fell off !!!! No damage done though, so loctite definately required here.!

And finally, towards the end of the afternoon, it was very pleasing to see her ticking over with just less then 20 lbs on the clock whilst notched back one. A very differen exhaust note and smooth as you like even with no flywheel.

cheers

Rick

with 50 on the clock and blower on, soon got to 70. Starting to get a feel for putting water in balancing it with a decent fire to maintain the heat when the injector takes the steam.

I was quite surprised how much steam the injector uses. It worked superbly - anything over 70 psi is fine all the way up to 180 when the safeties blew off.

The water lifter was also brilliant and doesn't use much steam up. Empies a two gallon watering can in about a minute - it's amazing.

I have had five main problems through the day -

1. Both unions on the water pump lead like a sieve and I couldn't get any water into the boiler with the pump at all. No other leaks from the pump but I have a leak from the union into the water tank at the tender top.

The clack valve was constantly hot but the delivery pipe was cold. It looked like a pretty major leak but I'm ot experienced in these things to tell if any was going in so I concentrated on the injector, which never failed to pick up. At one one point it was picking up down to just over 50 on the clock.

2. Same problem as Highpressure with the starting valve. Not sure whats going on but it does seem that the valve is not always shutting. When the engine stalls it sometimes started of it's own accord if the reverser was full forward or reverse.

3. I struggled with the lubricator all day. Steam or air was blowing by the one way valve as bubbles were appearing in the oil box. I loosened off the pipe to the one way and could feel it pressurise. Put it back on but still the oil level was not going down in the box. I ended up squirting oil in through the non return valve manually.

Anyone any ideas as to what could be wrong. Maybe not enough pumping pressure and a leaky non return valve ??

4. The steam valve for the injector does not have a good steam tight seal. I had to really close it hard with the aid of a pair of pliers. As the pressure increased I then couldn't open the valve which casued a bit of concern as I was dow to 1/4 glass. I took the wheel off and put a nut either side of it so I could get a spanner on it to aid opening and closing. It shouldn't be like this and I will speak to Steve as this is the second one I've had a problem with.

5. Again as per Highpressure - the whistle valve continues to leak like a sieve.

Oh yeah - and the oiler for the water pump fell off !!!! No damage done though, so loctite definately required here.!

And finally, towards the end of the afternoon, it was very pleasing to see her ticking over with just less then 20 lbs on the clock whilst notched back one. A very differen exhaust note and smooth as you like even with no flywheel.

cheers

Rick

Rickster- Number of posts : 267

Location : canterbury, Kent

Registration date : 2010-02-19

Re: Steaming again!!

Re: Steaming again!!

Hi Rick,

Glad to hear you had a good go a steaming and reassuring to know that I haven't made major mistakes but this is the teethinhg process. You didnt mention state of cleanliness???

In reply,

1. Haven't had a problem with the actually mating of the unions, the only thing I could suggest would be to take the pipe off and make sure both ends of the unions are nice and flat perhaps by rubbing them on wet and dry, otherwise I would have expected it to seal OK, check that its not water blowign by the union to the pipe joint.I thought it wasn't tight enough but closer inspection revealed the lack of solder, as there are so many to make one or two can get missed. The problem you normally get with the clack is the ball and seat get dirty and let steam push back through the pump, makes a gurling sound in the tender and the pipe gets hot, if its cold it normally means that at least something is going in. Take the ball out and clean it and the seat, but on the last enigne I fitted viton rubber balls as they are a bit more forgiving when diry although the heat from the boiler can cause problems with the disintegrating, I think we wil just have to see how that goes.

2. Need to take the starting valve off and get another ball and whack it on the seat to give it a face to take the ball system better, otherwise we may have to speak to STW to see how best to get it to seal.

3. Sounds like the non return valve not sealing properly, if you have made the oiler as per instructions it should pump as oil won't compress but of course oil floats on water so once that gets back to the oiler box it seems to stop the pump working correctly. My non return worked OK but I also have a spare in my odds and sods box, they're not too expensive when you visit a show with a trader or STW send another out.

4. Had the same problem with the base not seating right on the globe valve and being very tight, I intend to take it out and give the fitting a quick going over with lapping paste to try and get a better seat on both sides. The other way to loosen it off is to undo the stem fitting into the valve body releasing the stem, then you can open it up by hand. I'll let you know if lapping it in has any resluts.

5. Just keep remaking it with either tape or liquid PTFE or both!!!!

I have the week off and with an improving forecast hope to steam perhaps Tuesday so will give a report then to see if these cures work. Once the fire looses it flames it tends to be difficult to raise steam as the flames need to go through the tubes to get the heat transfer (I have found). Crappy smokey house coal seems to get quite a good head of steam as it burns well, anthracite whilst smelling nice and keeping things clean doesnt have much flame so needs quite a draft to get the heat into the boiler.

Looks like it just you and me at it at the moment then Rick.

Glad to hear you had a good go a steaming and reassuring to know that I haven't made major mistakes but this is the teethinhg process. You didnt mention state of cleanliness???

In reply,

1. Haven't had a problem with the actually mating of the unions, the only thing I could suggest would be to take the pipe off and make sure both ends of the unions are nice and flat perhaps by rubbing them on wet and dry, otherwise I would have expected it to seal OK, check that its not water blowign by the union to the pipe joint.I thought it wasn't tight enough but closer inspection revealed the lack of solder, as there are so many to make one or two can get missed. The problem you normally get with the clack is the ball and seat get dirty and let steam push back through the pump, makes a gurling sound in the tender and the pipe gets hot, if its cold it normally means that at least something is going in. Take the ball out and clean it and the seat, but on the last enigne I fitted viton rubber balls as they are a bit more forgiving when diry although the heat from the boiler can cause problems with the disintegrating, I think we wil just have to see how that goes.

2. Need to take the starting valve off and get another ball and whack it on the seat to give it a face to take the ball system better, otherwise we may have to speak to STW to see how best to get it to seal.

3. Sounds like the non return valve not sealing properly, if you have made the oiler as per instructions it should pump as oil won't compress but of course oil floats on water so once that gets back to the oiler box it seems to stop the pump working correctly. My non return worked OK but I also have a spare in my odds and sods box, they're not too expensive when you visit a show with a trader or STW send another out.

4. Had the same problem with the base not seating right on the globe valve and being very tight, I intend to take it out and give the fitting a quick going over with lapping paste to try and get a better seat on both sides. The other way to loosen it off is to undo the stem fitting into the valve body releasing the stem, then you can open it up by hand. I'll let you know if lapping it in has any resluts.

5. Just keep remaking it with either tape or liquid PTFE or both!!!!

I have the week off and with an improving forecast hope to steam perhaps Tuesday so will give a report then to see if these cures work. Once the fire looses it flames it tends to be difficult to raise steam as the flames need to go through the tubes to get the heat transfer (I have found). Crappy smokey house coal seems to get quite a good head of steam as it burns well, anthracite whilst smelling nice and keeping things clean doesnt have much flame so needs quite a draft to get the heat into the boiler.

Looks like it just you and me at it at the moment then Rick.

Re: Steaming again!!

Re: Steaming again!!

Oh yeah - forgot the clean bit - definately not. Absolutely covered in crap - minging ! Still, it was a very enjoyable day and I learnt a lot from it.

I think the problem with the water pump pipe is same you Kev - not enough solder. Also I think water is bypassing back but it didn't leak when I steamed before the pipe was fitted, so it may just need to be cleaned out.

cheers

Rick

I think the problem with the water pump pipe is same you Kev - not enough solder. Also I think water is bypassing back but it didn't leak when I steamed before the pipe was fitted, so it may just need to be cleaned out.

cheers

Rick

Rickster- Number of posts : 267

Location : canterbury, Kent

Registration date : 2010-02-19

Re: Steaming again!!

Re: Steaming again!!

Us laggards really appreciate you folks finding all the faults ahead of us!

Tim

Tim

Tim Watson- Number of posts : 585

Location : Herts

Registration date : 2008-07-02

Re: Steaming again!!

Re: Steaming again!!

Starting valve

I have been having a look at that. I got mine working better with the ball whacked in to give a seat. But the spring is quite week and possibly too short to snap the valve shut and the resistance of the O ring will hold the valve open.

I am on my second injector globe valve and this one is just the same. The seat is ragged and possibly slightly off centre. Could be a bad batch of valve bodies?

Only had 50psi air on the clock and hissing all over. So now at the point of chasing leaks.

I have been having a look at that. I got mine working better with the ball whacked in to give a seat. But the spring is quite week and possibly too short to snap the valve shut and the resistance of the O ring will hold the valve open.

I am on my second injector globe valve and this one is just the same. The seat is ragged and possibly slightly off centre. Could be a bad batch of valve bodies?

Only had 50psi air on the clock and hissing all over. So now at the point of chasing leaks.

lynnr- Number of posts : 3242

Age : 55

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Steaming again!!

Re: Steaming again!!

Hi Lynn,

i did wonder about the spring in the starting valve, as you say, it is quite feeble but not knowing any better assumed that is the way it should be.

I'll try re-seating the ball in the valve and see if I can get a stronger spring.

With the globe valve, because it's a screw thread, is there anything that can be done to improve the seat. Mine looks as bad as first one I had.

i did wonder about the spring in the starting valve, as you say, it is quite feeble but not knowing any better assumed that is the way it should be.

I'll try re-seating the ball in the valve and see if I can get a stronger spring.

With the globe valve, because it's a screw thread, is there anything that can be done to improve the seat. Mine looks as bad as first one I had.

Rickster- Number of posts : 267

Location : canterbury, Kent

Registration date : 2010-02-19

Re: Steaming again!!

Re: Steaming again!!

Unless you have a turning with a smooth bore instead of the stem body you can not keep centred and at tangent to grind the seat.

lynnr- Number of posts : 3242

Age : 55

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Steaming again!!

Re: Steaming again!!

Hi Lynn,

I intend to try the ball whacking ( for the starting valve that is

) to see if that sorts out the men from the boys so to speak

) to see if that sorts out the men from the boys so to speak  and will be in steam this week. Took globe valve apart and tried lapping the seat with the stem in a hand held drill, I'll let you know how that goes as well. Don't worry too much about air leaks, it can't get the expansion element of steam due to heat, cold water is the same, either lots of PTFE tape or the liquid. I have just remade both the whistle base and gauge globe tonight and again will report back when tried.

and will be in steam this week. Took globe valve apart and tried lapping the seat with the stem in a hand held drill, I'll let you know how that goes as well. Don't worry too much about air leaks, it can't get the expansion element of steam due to heat, cold water is the same, either lots of PTFE tape or the liquid. I have just remade both the whistle base and gauge globe tonight and again will report back when tried.

Nearly there......

I intend to try the ball whacking ( for the starting valve that is

Nearly there......

Re: Steaming again!!

Re: Steaming again!!

Poor old Madeline has been sitting in the trailer waiting for a rally that hasn't been cancelled. Still, Frederick has made much more progress than expected! Just fitted the painted cleading and the belly tanks: pictures soon.

Tim

Tim

Tim Watson- Number of posts : 585

Location : Herts

Registration date : 2008-07-02

Re: Steaming again!!

Re: Steaming again!!

The spring size in the Starting Valve and the Whistle really shouldn’t matter. It’s only there to keep the ball on its seat until steam pressure takes over. Think of the Check Valves on either side of the Boiler. There’s no spring at all so it’s only gravity holding the ball down. The Starting Valve is basically just a Check Valve and the operating rod just pushes the ball off its seat. It could be that the rod may be binding either caused by over tightening the Gland or perhaps insufficient clearance between the Rod and the Valve Body.

Regards

Steve

Regards

Steve

Some Good stuff some Bad

Some Good stuff some Bad

Well got a chance to test out all that had been taken apart and remade with sealant to find that none of it has worked really  . The whistle base still leaks, the globe valve body on the gauge leaks rather than the fitting for the stem, the injector globe won't seal at all despite crudely having a go at the base with the stem in a hand drill, but worst of all was the water pump, despite curing the leak at the mating face and F-I-L re soldering the union when I went to pump it did so for a few seconds before a pin hole on the very back of the casting above the bypass appeared and shot water all over the footplate again, so I spoke to Steve. Good news is with the usual efficiency the spares are coming out tonignt. As I have a week off I hope to get them on the engine and steam before the weekend so we'll see how that goes.

. The whistle base still leaks, the globe valve body on the gauge leaks rather than the fitting for the stem, the injector globe won't seal at all despite crudely having a go at the base with the stem in a hand drill, but worst of all was the water pump, despite curing the leak at the mating face and F-I-L re soldering the union when I went to pump it did so for a few seconds before a pin hole on the very back of the casting above the bypass appeared and shot water all over the footplate again, so I spoke to Steve. Good news is with the usual efficiency the spares are coming out tonignt. As I have a week off I hope to get them on the engine and steam before the weekend so we'll see how that goes.

On the positive side I did get to the point where the safeties lifted as the injector works a treat so not scared about water level, and what a superbly efficient beast they are compared to previous engines. As far as I could tell only one lifted with ease at exactly 180 psi and within 15 seconds or so was back to 160 and it snapped shut. Despite a full blower it only needed one every time so that part of the steam test won't present any issues at all.

Didn't manage to get the engine to run much at all disappointingly, as the pressure got the other side of 80 or so it became increasingly more difficult to get it to start, I mistakenly made the assumption something had started to run hot and seize up but when the fire had gone but all was still hot I could turn the crank by hand. The only thing I can think of is that the starting valve is causing the LP cylinder to resist the HP motion, don't know how, doesn't seem to be logical but seems to fit the results seen so, to that end, for the next steaming as a test I have blocked off the input to the LP chest just to see what it does. I can also report a huge amount of water retained in the LP exhaust and when I took out the grub screw in the base of the cylinder in the LP exhaust I was very lucky not to get seriously scalded by the jet of steam and water that came out despite being in mid gear and no regulator so the valve chest must be under pressure from somewhere???

Fire box appear to have got past the point where it creates lots of condesation now, despite a virtually still day still got the the point where the blower kicks in at about 45 mins in.

Forgot to add the whistle it self is a bit disappointing but I think that's because I don't have the base made up properly yet but the siren... Holy Cow Batman... I used to enjoy it on the old engine but it always needed to be over 70 or so the get it to sound good, when I was up at 150 - 180 not only did it sound spectacluar but it took up so quick with such a superb sound, much better at higher pressures

Holy Cow Batman... I used to enjoy it on the old engine but it always needed to be over 70 or so the get it to sound good, when I was up at 150 - 180 not only did it sound spectacluar but it took up so quick with such a superb sound, much better at higher pressures

On the positive side I did get to the point where the safeties lifted as the injector works a treat so not scared about water level, and what a superbly efficient beast they are compared to previous engines. As far as I could tell only one lifted with ease at exactly 180 psi and within 15 seconds or so was back to 160 and it snapped shut. Despite a full blower it only needed one every time so that part of the steam test won't present any issues at all.

Didn't manage to get the engine to run much at all disappointingly, as the pressure got the other side of 80 or so it became increasingly more difficult to get it to start, I mistakenly made the assumption something had started to run hot and seize up but when the fire had gone but all was still hot I could turn the crank by hand. The only thing I can think of is that the starting valve is causing the LP cylinder to resist the HP motion, don't know how, doesn't seem to be logical but seems to fit the results seen so, to that end, for the next steaming as a test I have blocked off the input to the LP chest just to see what it does. I can also report a huge amount of water retained in the LP exhaust and when I took out the grub screw in the base of the cylinder in the LP exhaust I was very lucky not to get seriously scalded by the jet of steam and water that came out despite being in mid gear and no regulator so the valve chest must be under pressure from somewhere???

Fire box appear to have got past the point where it creates lots of condesation now, despite a virtually still day still got the the point where the blower kicks in at about 45 mins in.

Forgot to add the whistle it self is a bit disappointing but I think that's because I don't have the base made up properly yet but the siren...

Holy Cow Batman... I used to enjoy it on the old engine but it always needed to be over 70 or so the get it to sound good, when I was up at 150 - 180 not only did it sound spectacluar but it took up so quick with such a superb sound, much better at higher pressures

Holy Cow Batman... I used to enjoy it on the old engine but it always needed to be over 70 or so the get it to sound good, when I was up at 150 - 180 not only did it sound spectacluar but it took up so quick with such a superb sound, much better at higher pressures  Re: Steaming again!!

Re: Steaming again!!

My whistle works quite nice on anything from 50psi to 150psi (max on the compressor) I tuned the trumpet to the higher pressure as it does not sound good at lower pressures now. Quite loud as well once you get the sweet spot.

Got a nice wind blowing today so may try a test firing tonight. First under pressure both ways. Mechanical and mind

Got a nice wind blowing today so may try a test firing tonight. First under pressure both ways. Mechanical and mind

lynnr- Number of posts : 3242

Age : 55

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Steaming again!!

Re: Steaming again!!

I Should add the whistle is the four tuned fancy looking chap from Polly models not the one supplied.

Re: Steaming again!!

Re: Steaming again!!

I took my full size whistle off as it wouldn't sound with the supplied steam valve, I think it needs the next size up and put it in the whole made for a siren, so I'm back to the supplied one for the next steamig session which I hope will be this weekend.

Done most the jobs needed - silver soldered both ends of the water pump delivery pipe, found the problem with the oil pump - missing ball bearing, now replaced. I'd forgotten to put it back in after stripping the pump down for painting.

I think the problem with the starting valve opening is because the regulat rod wasn't adjusted correctly which meant as it was pushed fully open there wasn't enough movement available in the starting valve slot. When the regulator was fully open it was catching right on the end of this slot and just pushing on the starting lever pin opening the starting valve slightly.

I've also silve soldered a piece of 3mm brass onto the slow running valve to restrict the opening to one hole rather than three. Now when the regulator goes from fully closed to fully open the main opening in the regulator chest is almost fully open - all bar maybe 2mm.

I'll report back when next in steam as to who this has gone.

Been round all the nuts and bolts on the spec plates, main bearing housings and hornplate bolts and was really suprised how things had "loosened off". I needed to tighten them all and I guess this is due to the paint hardening off with the steaming and giving a little.

As Highpressure found, I also suffered from condensation and had to sponge out the smokebox as I could hear gurgling coming from the front end and the condensate was almost running back down the the lower tubes into the firebox!

So all fine and dandy now, just needs a damn good clean.

cheers

Rick

Done most the jobs needed - silver soldered both ends of the water pump delivery pipe, found the problem with the oil pump - missing ball bearing, now replaced. I'd forgotten to put it back in after stripping the pump down for painting.

I think the problem with the starting valve opening is because the regulat rod wasn't adjusted correctly which meant as it was pushed fully open there wasn't enough movement available in the starting valve slot. When the regulator was fully open it was catching right on the end of this slot and just pushing on the starting lever pin opening the starting valve slightly.

I've also silve soldered a piece of 3mm brass onto the slow running valve to restrict the opening to one hole rather than three. Now when the regulator goes from fully closed to fully open the main opening in the regulator chest is almost fully open - all bar maybe 2mm.

I'll report back when next in steam as to who this has gone.

Been round all the nuts and bolts on the spec plates, main bearing housings and hornplate bolts and was really suprised how things had "loosened off". I needed to tighten them all and I guess this is due to the paint hardening off with the steaming and giving a little.

As Highpressure found, I also suffered from condensation and had to sponge out the smokebox as I could hear gurgling coming from the front end and the condensate was almost running back down the the lower tubes into the firebox!

So all fine and dandy now, just needs a damn good clean.

cheers

Rick

Rickster- Number of posts : 267

Location : canterbury, Kent

Registration date : 2010-02-19

Page 1 of 3 • 1, 2, 3

Page 1 of 3

Permissions in this forum:

You cannot reply to topics in this forum|

|

|