Putting together a Burrel in Duesseldorf

4 posters

Page 1 of 1

Putting together a Burrel in Duesseldorf

Putting together a Burrel in Duesseldorf

Boiler arrived in Duesseldorf:

In the second week of January the boiler arrived. At last! The delivery procedure came out as a nightmare. Three times STW sent it on the way, three times it came back to Daventry a few weeks later. What was the reason: It was DPD who got the parcel in their fingers, but obviously they were not able to handle the customs-requirements properly. It was easier for them to send the parcel back to the supplier. I talked to Rosemary and recommended to use DHL, which belongs to the Deutsche Post. With them it worked perfectly, and they were pretty fast. They informed me to pay for customs, the payment I could do online, and two days later I received the parcel.

Unpacking the boiler was quite an excitement for me. But it took me some time to blow all the styrofoam-particles out. I hope I did not forget too many of them.

Next problem:

I had to decide where to put the subassemblies of my Burrel together. It should be a place where the machine could stay the rest of time until finishing. Furthermore it should be a place where I could get access from all sides. I found this place beside my circular table saw after taking away it's slide table.

Before I had got the boiler I had already received the kits no.14 (Cladding & ashpan), no. 15 (Steering) and 16A (Crank & conrod). Then, within a short period of time, Rosemary sent me the kits no. 16B, 17, 18 and 19. A huge amount of parts waiting for assembly!

Taking apart tender & hornplates:

Before starting the assembly I had to separate the tender and the steering mechanism from the hornplates. Doing that I ran into some problems: One of the hex head fasteners broke, the rest of it stuck in the LH-hornplate, no chance to get it out. Things like that should not happen, thats's poor quality! To repair it I had to mill a bigger hole into the hornplate and to braze an adequate piece of steel into the hole, and finally drill and tap a new hole.

And it was impossible for me to take out some of the countersunk socket screws, because the hexagon sockets were worn out. Again, poor quality!

To prevent further problems I decided to replace all critical hex head screws by new ones in the best quality (8.8) which I could get in Germany. And all countersunk socket screws which I could get out I replaced by countersunk screws with TORX-drive. And those which I could not get out: Thank God it was not really essential to get them out, so I decided to leave them where they were.

My urgent appeal to STW:

Critical hex head fasteners in best quality only, coutersunk socket screws with TORX-drive only!

Putting the subassemblies together:

I decided to start with the smokebox. The nuts in the inside are difficult to handle. It is easier to turn and flip the naked boiler without hornplates hanging on it.

In the second week of January the boiler arrived. At last! The delivery procedure came out as a nightmare. Three times STW sent it on the way, three times it came back to Daventry a few weeks later. What was the reason: It was DPD who got the parcel in their fingers, but obviously they were not able to handle the customs-requirements properly. It was easier for them to send the parcel back to the supplier. I talked to Rosemary and recommended to use DHL, which belongs to the Deutsche Post. With them it worked perfectly, and they were pretty fast. They informed me to pay for customs, the payment I could do online, and two days later I received the parcel.

Unpacking the boiler was quite an excitement for me. But it took me some time to blow all the styrofoam-particles out. I hope I did not forget too many of them.

Next problem:

I had to decide where to put the subassemblies of my Burrel together. It should be a place where the machine could stay the rest of time until finishing. Furthermore it should be a place where I could get access from all sides. I found this place beside my circular table saw after taking away it's slide table.

Before I had got the boiler I had already received the kits no.14 (Cladding & ashpan), no. 15 (Steering) and 16A (Crank & conrod). Then, within a short period of time, Rosemary sent me the kits no. 16B, 17, 18 and 19. A huge amount of parts waiting for assembly!

Taking apart tender & hornplates:

Before starting the assembly I had to separate the tender and the steering mechanism from the hornplates. Doing that I ran into some problems: One of the hex head fasteners broke, the rest of it stuck in the LH-hornplate, no chance to get it out. Things like that should not happen, thats's poor quality! To repair it I had to mill a bigger hole into the hornplate and to braze an adequate piece of steel into the hole, and finally drill and tap a new hole.

And it was impossible for me to take out some of the countersunk socket screws, because the hexagon sockets were worn out. Again, poor quality!

To prevent further problems I decided to replace all critical hex head screws by new ones in the best quality (8.8) which I could get in Germany. And all countersunk socket screws which I could get out I replaced by countersunk screws with TORX-drive. And those which I could not get out: Thank God it was not really essential to get them out, so I decided to leave them where they were.

My urgent appeal to STW:

Critical hex head fasteners in best quality only, coutersunk socket screws with TORX-drive only!

Putting the subassemblies together:

I decided to start with the smokebox. The nuts in the inside are difficult to handle. It is easier to turn and flip the naked boiler without hornplates hanging on it.

karl heinz marschner- Number of posts : 33

Location : Duesseldorf, Germany

Registration date : 2021-04-13

Simon C likes this post

Re: Putting together a Burrel in Duesseldorf

Re: Putting together a Burrel in Duesseldorf

Hi Karl-Heinz,

quite some trouble with DPD, then, but got sorted in the end.

Re Inhex, yes good advice to use only 8.8 grade, never had an issue with that, but then again the threads are larger on Pied Piper

Greetings

Elwood

quite some trouble with DPD, then, but got sorted in the end.

Re Inhex, yes good advice to use only 8.8 grade, never had an issue with that, but then again the threads are larger on Pied Piper

Greetings

Elwood

elwood-59- Number of posts : 300

Location : Germany-NRW

Registration date : 2014-12-17

karl heinz marschner likes this post

Re: Putting together a Burrel in Duesseldorf

Re: Putting together a Burrel in Duesseldorf

Smoke Box:

In my post "news from Duesseldorf, Sept 13, 2022" I was very proud of my special attachment to prevent the draw bar from being pushed into the smoke box when locking the door. Now this attachment makes it practically impossible to attach the nuts inside the smokebox. To remove this attachment was the only way to overcome this problem.

In the bottom area of the smoke box I used some Foliac to get a tight connection to the boiler.

Fire door:

Before putting the parts of the door mechanism together I blackened the parts. I used a cold blackening liquid for steel. The result is far from being perfect, but I like it as it is. For me it was the first time using Star washers. I think they are just perfect for things like that. There was only one location where it was not enough room for a star washer. I did some peening instead which came out very well. I attached the door mechanism to the boiler before mounting the hornplates. The door mechanism collided with the lower water gauge extension (BU 21228). I had to take it on my lathe to machine some material off from it.

Boiler - Hornplate - Assembly:

My urgent recommendation before putting boiler and hornplates together:

- Fix the firedoor mechanism onto the boiler before attaching the horn plates. Afterwards it would be impossible.

- Fix the two steam elbows (BU21229) with locknuts to the boiler.

- Fix the lower water gauge extension (BU 21228) to the boiler.

- Fix the fusible plug to the inside top wall of the firebox. You have to flip the boiler upside down to get access to the bore.

- Fix the three pipe clamps (2 pcs BU 21225 and 1 pc BU 21226) to the hornplates

Very quickly I found out that the width between the hornplates was not wide enough to get the boiler in between. Years ago i made me a set of adjustable spacers, which I tried now.

Thank God I did not procede with this method. I made some measurements instead and came to these results:

Width of boiler . . . . . . . . . . . . . . . . 125,3 - 125,8 mm

Width of rear spectacle plate . . . . . . 125,8

Width of front spectacle plate . . . . . 124,4

Width of rear axle tube . . . . . . . . . . 125,0

To correct the differences of widths I made two shims:

- One 1,4 mm shim for the front spectacle plate

- One 0,7 mm shim for the rear axle tube

Now I could put the hornplates over the boiler relatively easy. Before doing that I had loosened all fasteners which held the hornplates together. I did not dismantle the crank shaft. I put two 10 mm blocks underneath the hornplates to bring them exactly to the same height as the boiler, so the holes for the fasteners would match. After I had fastened everything I was very curious: Would the crankshaft turn as smoothly as it did before? It did, even somewhat better. Big compliment to Steam Traction World!

Tender:

I had no problems to attach the tender to the hornplates. Now it was time to find some adequate wooden blocks to put them underneath the front axle and the tender. Now it is possible to freely push the front wheels and the rear wheels onto their axles whenever I want.

Mounting the cylinder onto the boiler:

Before attaching any Foliac I made a test, wether all the M4x20 studs would fit into the holes of the cylinder base plate. They did not, so I had to file the holes of the outward rows into slots. After that I followed the instructions, attached the Foliac as described and fastened the nuts in the specified sequence. Two days later I fastened them the last time.

I hope the assembly will turn out to be tight, because I would not like to take it apart once more. When it comes to painting I will dismantle the fittings only.

Boiler Cladding:

I have to admit I was somewhat nervous when starting the boiler cladding. I had read some scary stories about it in the forum. Now I can say it was not as bad at all. Nevertheless it was challenging.

Before fitting the cork insulation and metal cladding I recommend to remove the steering chain shaft (BU 21507) and the guide bars for the cross head. It makes it a lot easier.

The cork insulation did not fit very well, so I had to be very careful when cutting out the openings for the weigh shaft bracket, the man hole cover nut (BU 21437) and for the two feed clack bushes.

To get the man hole cover nut tight onto the boiler surface I had to file down one of the copper studs.

The rear cladding was approximately 2 mm too long, so it hit the front spectacle plate. I did not file these 2 mm away. Instead of that I widened the round bottom area of the spectacle plate. So the cladding can go underneath, the spectacle plate can hold it down.

Other than that I had no problems to fit the cladding sheets onto the boiler. With one exception:

To get the fasteners of the rear boiler band into the right position I had to file down two of the copper studs in the front wall of the firebox. I used a German version of a Dremel. It was a very nervy and tiresome procedure. It would have been much easier to do this with the naked boiler. If I had only known!

Cylinder Cladding:

Putting the cladding onto the cylinde was challenging. To get the cladding sheet close enough to the shape of the cylinder I had to remove one complete row of the fasteners, M4 grub screws and nuts.

Then a minor catastrophe happened: When I tried to get the first 8BA fastener with it's slit head into it's hole I dropped it and it fell head over heels into one of the open holes for the grub screws. My smallest gripping pliers failed to get it out. So I had to make me an instrument, some sort of loop out of thin wire. It was a cumbersome precision work. In Germany we call that kind of time-consuming labour Fummelei. But Fummelei has two meanings, and the englisch translation knows the second meaning only which is petting. Anyway I got it out at last. To prevent further disasters I put adhesive tape over the open holes.

And I changed the 8BA taps to M2,5 taps. 8BA and M2,5 have the same pitch and there is only a small difference in diameter so you can easily run a set of M2,5 taps into the holes. My M2,5 hexagon head screws are much easier to handle in comparison to the slit ball heads of the 8BA.

The holes in the cladding sheet dit not match with the holes in the cylinder. I had to do a lot of very nervy filing to convert them into adeqate slots. In the end the cladding sheet looked rather poor. Thank God the two brass bands do a good job to hide these blemishes.

The kit included two short brass bands which were provided to complete the cylinder cladding. You better forget these. I found it impossible to fit them below the two drain bushes of the cylinder. Instead of these bands I made a 62 mm long brass bar with semicircular profile which I could fit as a horizontal completion underneath the drain bushes. See photo above.

Furthermore the elliptical opening for the steam whistle flange did not match really well. I think I will live with it. Without having a dimensional drawing of the cylinder it would be difficult to design a new cladding sheet.

In my post "news from Duesseldorf, Sept 13, 2022" I was very proud of my special attachment to prevent the draw bar from being pushed into the smoke box when locking the door. Now this attachment makes it practically impossible to attach the nuts inside the smokebox. To remove this attachment was the only way to overcome this problem.

In the bottom area of the smoke box I used some Foliac to get a tight connection to the boiler.

Fire door:

Before putting the parts of the door mechanism together I blackened the parts. I used a cold blackening liquid for steel. The result is far from being perfect, but I like it as it is. For me it was the first time using Star washers. I think they are just perfect for things like that. There was only one location where it was not enough room for a star washer. I did some peening instead which came out very well. I attached the door mechanism to the boiler before mounting the hornplates. The door mechanism collided with the lower water gauge extension (BU 21228). I had to take it on my lathe to machine some material off from it.

Boiler - Hornplate - Assembly:

My urgent recommendation before putting boiler and hornplates together:

- Fix the firedoor mechanism onto the boiler before attaching the horn plates. Afterwards it would be impossible.

- Fix the two steam elbows (BU21229) with locknuts to the boiler.

- Fix the lower water gauge extension (BU 21228) to the boiler.

- Fix the fusible plug to the inside top wall of the firebox. You have to flip the boiler upside down to get access to the bore.

- Fix the three pipe clamps (2 pcs BU 21225 and 1 pc BU 21226) to the hornplates

Very quickly I found out that the width between the hornplates was not wide enough to get the boiler in between. Years ago i made me a set of adjustable spacers, which I tried now.

Thank God I did not procede with this method. I made some measurements instead and came to these results:

Width of boiler . . . . . . . . . . . . . . . . 125,3 - 125,8 mm

Width of rear spectacle plate . . . . . . 125,8

Width of front spectacle plate . . . . . 124,4

Width of rear axle tube . . . . . . . . . . 125,0

To correct the differences of widths I made two shims:

- One 1,4 mm shim for the front spectacle plate

- One 0,7 mm shim for the rear axle tube

Now I could put the hornplates over the boiler relatively easy. Before doing that I had loosened all fasteners which held the hornplates together. I did not dismantle the crank shaft. I put two 10 mm blocks underneath the hornplates to bring them exactly to the same height as the boiler, so the holes for the fasteners would match. After I had fastened everything I was very curious: Would the crankshaft turn as smoothly as it did before? It did, even somewhat better. Big compliment to Steam Traction World!

Tender:

I had no problems to attach the tender to the hornplates. Now it was time to find some adequate wooden blocks to put them underneath the front axle and the tender. Now it is possible to freely push the front wheels and the rear wheels onto their axles whenever I want.

Mounting the cylinder onto the boiler:

Before attaching any Foliac I made a test, wether all the M4x20 studs would fit into the holes of the cylinder base plate. They did not, so I had to file the holes of the outward rows into slots. After that I followed the instructions, attached the Foliac as described and fastened the nuts in the specified sequence. Two days later I fastened them the last time.

I hope the assembly will turn out to be tight, because I would not like to take it apart once more. When it comes to painting I will dismantle the fittings only.

Boiler Cladding:

I have to admit I was somewhat nervous when starting the boiler cladding. I had read some scary stories about it in the forum. Now I can say it was not as bad at all. Nevertheless it was challenging.

Before fitting the cork insulation and metal cladding I recommend to remove the steering chain shaft (BU 21507) and the guide bars for the cross head. It makes it a lot easier.

The cork insulation did not fit very well, so I had to be very careful when cutting out the openings for the weigh shaft bracket, the man hole cover nut (BU 21437) and for the two feed clack bushes.

To get the man hole cover nut tight onto the boiler surface I had to file down one of the copper studs.

The rear cladding was approximately 2 mm too long, so it hit the front spectacle plate. I did not file these 2 mm away. Instead of that I widened the round bottom area of the spectacle plate. So the cladding can go underneath, the spectacle plate can hold it down.

Other than that I had no problems to fit the cladding sheets onto the boiler. With one exception:

To get the fasteners of the rear boiler band into the right position I had to file down two of the copper studs in the front wall of the firebox. I used a German version of a Dremel. It was a very nervy and tiresome procedure. It would have been much easier to do this with the naked boiler. If I had only known!

Cylinder Cladding:

Putting the cladding onto the cylinde was challenging. To get the cladding sheet close enough to the shape of the cylinder I had to remove one complete row of the fasteners, M4 grub screws and nuts.

Then a minor catastrophe happened: When I tried to get the first 8BA fastener with it's slit head into it's hole I dropped it and it fell head over heels into one of the open holes for the grub screws. My smallest gripping pliers failed to get it out. So I had to make me an instrument, some sort of loop out of thin wire. It was a cumbersome precision work. In Germany we call that kind of time-consuming labour Fummelei. But Fummelei has two meanings, and the englisch translation knows the second meaning only which is petting. Anyway I got it out at last. To prevent further disasters I put adhesive tape over the open holes.

And I changed the 8BA taps to M2,5 taps. 8BA and M2,5 have the same pitch and there is only a small difference in diameter so you can easily run a set of M2,5 taps into the holes. My M2,5 hexagon head screws are much easier to handle in comparison to the slit ball heads of the 8BA.

The holes in the cladding sheet dit not match with the holes in the cylinder. I had to do a lot of very nervy filing to convert them into adeqate slots. In the end the cladding sheet looked rather poor. Thank God the two brass bands do a good job to hide these blemishes.

The kit included two short brass bands which were provided to complete the cylinder cladding. You better forget these. I found it impossible to fit them below the two drain bushes of the cylinder. Instead of these bands I made a 62 mm long brass bar with semicircular profile which I could fit as a horizontal completion underneath the drain bushes. See photo above.

Furthermore the elliptical opening for the steam whistle flange did not match really well. I think I will live with it. Without having a dimensional drawing of the cylinder it would be difficult to design a new cladding sheet.

Last edited by karl heinz marschner on Tue 04 Apr 2023, 12:01 pm; edited 2 times in total (Reason for editing : I wrote the wrong date, Sept 2023 instead of Sept 2022. Furthermore: Now I say steam whistle instead of steam pipe)

karl heinz marschner- Number of posts : 33

Location : Duesseldorf, Germany

Registration date : 2021-04-13

Simon C likes this post

Re: Putting together a Burrel in Duesseldorf

Re: Putting together a Burrel in Duesseldorf

Steering Mechanism:

In the meantime I had found new steering chains with smaller chain links in one of our homeworkers shops. This chain was zinc-plated which I did not like. To remove the zinc I used hot citric acid which worked pretty well. You can see it in one of the photos above. After putting everything together I found out, when turning the steering wheel the worm and the worm-wheel tended to block each other. I solved the problem by adding a washer to reduce the axial shake of the chain shaft (BU 21507).

Ash Pan:

I had some problems to put the parts together. The front of the ashpan was not wide enough for the ashpan lid. I widened it by using my heavy vice. The lid collided with the nuts for the hinge bracket (BU 21421). So I had to cut out the corners of the lid.

A bigger problem were the ashpan retaining pins (BU 21412): The holes in the ashpan did not match with the holes at the bottom of the fire box. They did not match at all. On the right hand side I had to file both holes into pretty long slots. After that I did not like the result: The pin was hanging very sloppily in these slots. What did I do:

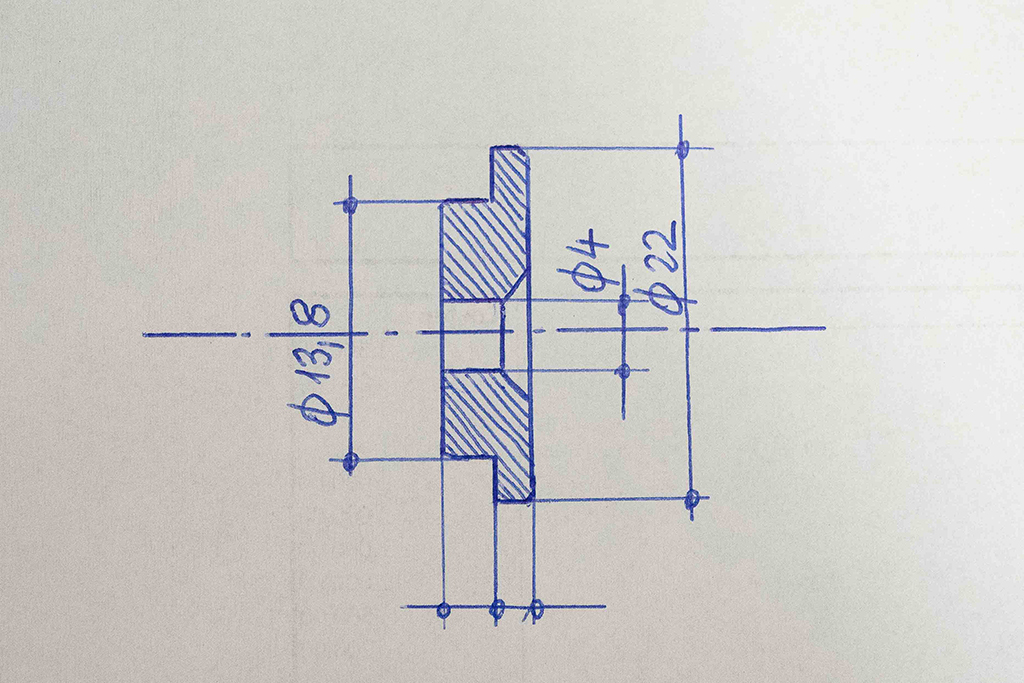

I machined a bigger hole (8mm) into the ashpan, brazed a thick piece of steel into it, and drilled a new hole in the correct location.

In the photo you can also see that I had to file some material out from the grate bars, because they collided with the retaining pins.

In the meantime I had found new steering chains with smaller chain links in one of our homeworkers shops. This chain was zinc-plated which I did not like. To remove the zinc I used hot citric acid which worked pretty well. You can see it in one of the photos above. After putting everything together I found out, when turning the steering wheel the worm and the worm-wheel tended to block each other. I solved the problem by adding a washer to reduce the axial shake of the chain shaft (BU 21507).

Ash Pan:

I had some problems to put the parts together. The front of the ashpan was not wide enough for the ashpan lid. I widened it by using my heavy vice. The lid collided with the nuts for the hinge bracket (BU 21421). So I had to cut out the corners of the lid.

A bigger problem were the ashpan retaining pins (BU 21412): The holes in the ashpan did not match with the holes at the bottom of the fire box. They did not match at all. On the right hand side I had to file both holes into pretty long slots. After that I did not like the result: The pin was hanging very sloppily in these slots. What did I do:

I machined a bigger hole (8mm) into the ashpan, brazed a thick piece of steel into it, and drilled a new hole in the correct location.

In the photo you can also see that I had to file some material out from the grate bars, because they collided with the retaining pins.

karl heinz marschner- Number of posts : 33

Location : Duesseldorf, Germany

Registration date : 2021-04-13

Simon C likes this post

Re: Putting together a Burrel in Duesseldorf

Re: Putting together a Burrel in Duesseldorf

Steam head assembly / steam head pipe / water gauge pipe:

Before starting to put these parts together it is better to wait for kit no. 16B, where the water gauge set is included. To get a better access to the top of the boiler I removed the crankshaft and the RH crankshaft bearing.

In a first step I mounted the upper part of the water gauge set to the water gauge bracket (see boiler BU 21227), and the lower part of the water gauge set to the lower water gauge extension (see boiler BU 21228) together with their 3/8"x32 lock nuts. The water gauge setting rod (BU 21624) helps to get the upper and the lower part in line. In my case I had to shorten the lower water gauge extension by a few millimeters.

In the next step I tried to fix the water gauge pipe (BU 21623). It did not fit and it was very, very difficult to make it's ends to match between the steam elbow and the upper part of the water gauge set. It is extremly hard to change the bending angles of a short pipe like this. Furthermore there is no chance to adjust the final length of the pipe, because it already had it's fittings at both ends. I was really afraid that I would fail. But to my upmost surprise, after several attempts I made it. Dem Ingenioer ist nichts zu schwoer - there is nothing too difficult for an engineer.

After doing this I attached the steam head with it's valves. Read the instructions carefully to get them in the right direction. With the steam head pipe I had the same problems. It was only a little bit easier insofar as the two bends of the pipe are in the same level. In the end both pipes looked pretty dented. I can only hope that I did not damage the fittings at their ends. Will they be tight enough under steam pressure? If not, I will have to fabricate new pipes, following my own well proven method using union cones, which can be brazed into the ends of the pipes.

A completely different problem was to get the RH crankshaft bearing back. How do I get the nuts and washers to their positions without dropping them. This is my trick:

I put some grease on my fingertip. The photo below shows how a small nut sticks pretty reliably, even when you transport it together with it's washer.

Weighshaft bracket:

After a short time of studying the situation I became aware that the bore for the main valve rod must be the reference point for setting and aligning the weighshaft bracket.

The weighshaft bracket shim (BU 21131) turned out to be too thick. I had to file it down from 2 mm to approximately 1,5 mm. And I had to change the holes in the baseplate of the weighshaft bracket into short slots. After this the main valve rod (BU 21916) could be pushed easily through the Iglidur bushes (BU 21916).

The bottom slide bar for the cross head could be fixed to the weighshaft bracket without any rework. The top slide bar (BU 21117) turned out to be too tight. Therefore I milled off approximately 0,2 mm.

Putting together the parts for the connecting rod made me no problems. But I did not like the long wedge (BU 21612). So I did not use it, and I shortened the long wedge bolt. As I already mentioned before, my Burrel will run under steam for a short time only, after this it will serve as a show piece.

Flywheel:

What a beautiful piece of equipment, I really like it. Therfore I did not understand the instructions which recommend to remove the casting skin. Why that? Nobody did that with the original. For the painting it would not make any difference. But I followed the instruction and filed two small flats into the crankshaft for the grub screws.

It was a great moment to turn the flywheel the first moment and to see how crankshaft, connecting rod, crosshead and piston rod work together smoothly.

Crankshaft gear guard:

There is a note in the instructions: One of the hexheads of the fasteners has to stay on the outside of the tender wall. You cannot get access to it after assembly of the differential. Therefore I made a special fastener which I could glue onto the outside of the tender wall using 2K-epoxy adhesive.

Differential and 2nd shaft gears:

In the forum I did not read about any problems to get the 1st & 2nd gear on the spline of the crankshaft. I had a problem: It took me several hours of nervy filing before I was able to slide these two small pinions onto the spline. Finally I added some grease, now I can easily slide them without any significant shake.

Also the other parts needed quite a bit of handwork to fit them together. Especially the four prongs of the differential locking ring did not fit into the slots of the inside bevel gear (BU 21701).

In the end I found out that the 2nd shaft is a little bit too short. Not a big problem, I solved it by making a new RH main spur gear washer (BU 21723).

After assembling everything I could still rotate the flywheel as freely as before. But the differential did not work, I could not move it at all. The bevel gears and bevel pinions blocked each other. My first thought was: Leave it as it is, the working of the differential is not essential for the final build. But this is not the way my mind works.

On the next day I removed the crank gear guard once more and took apart the differential. I made a new outside bevel thrust washer (BU 21713), 3,5 mm thick instead of 2,5 mm.

With this change the compensation centre (BU 21704) has got some axial clearance. It is much better now, but it still does not move really smoothly. The teeth of the bevels and the bevel pinions are probably not made precisely enough. Should they? I am not sure. Therefore I ask the other Burrel owners, did you make similiar experiences?

Final Drive and Winch:

I had no problems with the final drive gears. They fitted without any reworking.

Gear Guards:

The gear guards needed some filing to remove sharp edges. The LH gear guard fitted perfectly. For the RH gear guard I had to make washers with 2 mm, 3 mm and 4 mm thickness. Otherwise the gear wheels would have grazed the guards making nasty noises.

One of the fasteners (the one where the 4 mm washer was needed) would have had it's nut inside the water tank. I did not want to open this tank after I had sealed it's walls with liquid rubber. For this reason I provided this washer with a M3 tap and fixed it to the outside of the tender using 2K-epoxy adhesive.

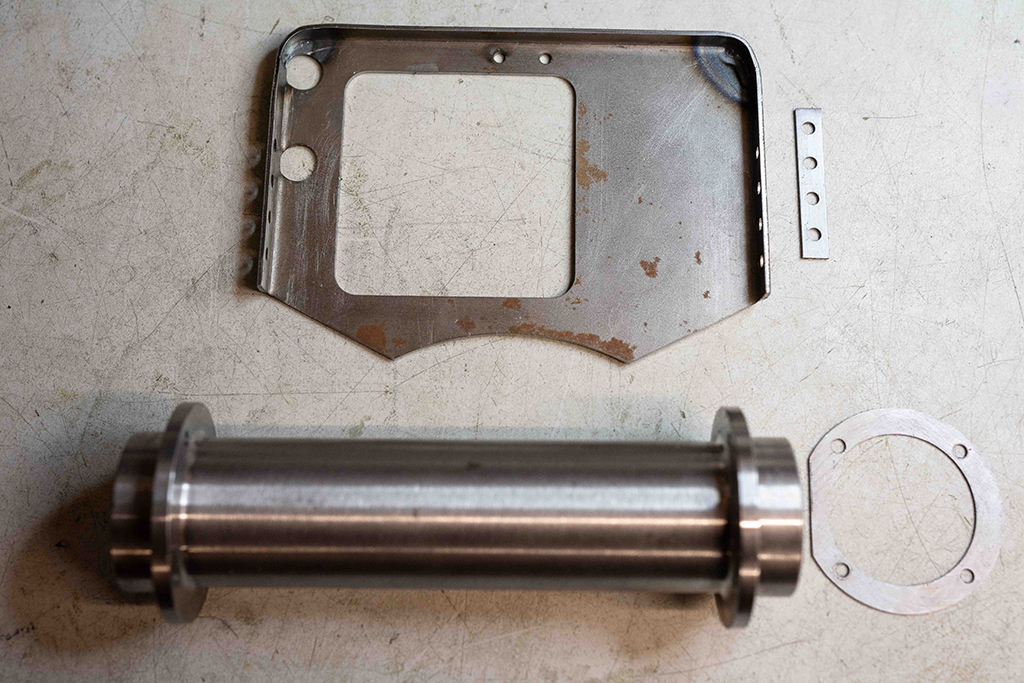

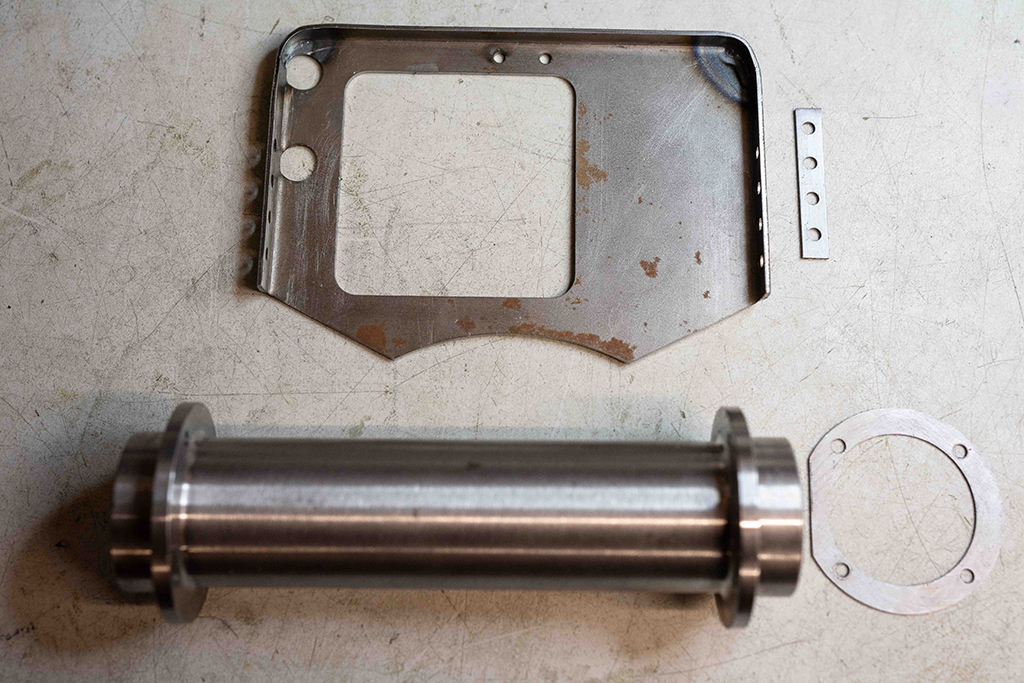

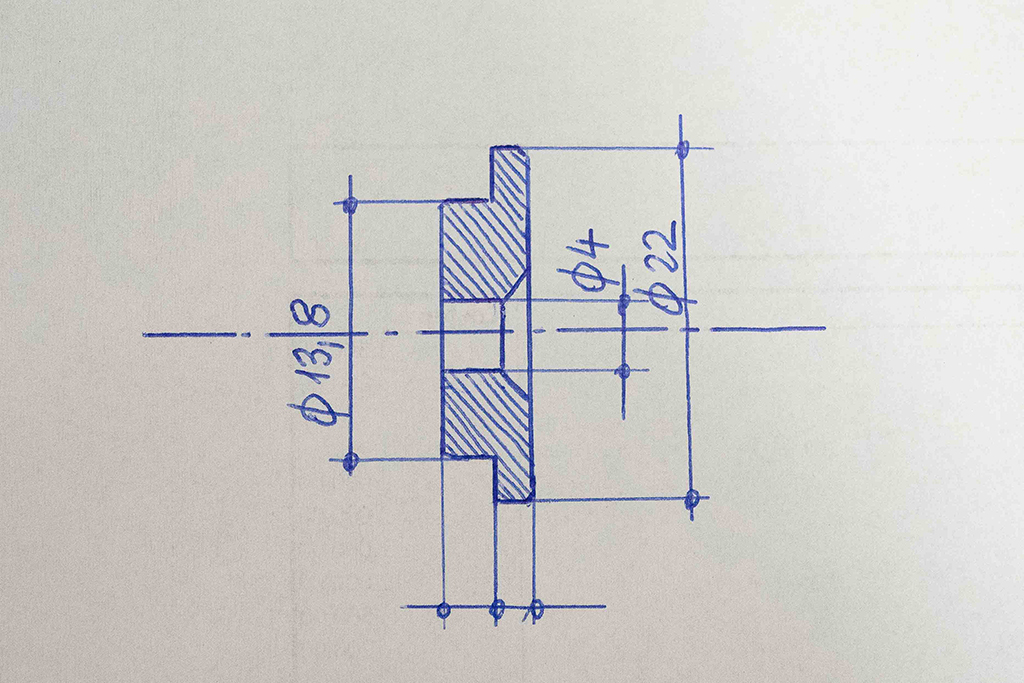

Wheel retaining collars for the rear wheels:

On the RH side the wheel retaining collar did not fit. The rear shaft was too short by about 2,5 mm. Therefore I shortened the RH final drive spacer (BU 21816) by 2,5 mm. Only to find out that this was definitely the wrong way to solve the problem. So I made a new washer to get the RH final drive spacer back to it's original length. A better way to solve the problem would have been taking 2,5 mm off from the final drive gear. But I did not like this idea. I decided instead to make the rear wheel shaft longer by approximately 2,8 mm. The shaft has 19 mm diameter. Therefor I made a short piece of steel with 20mm diameter with a 19 mm diameter collar 2 mm deep, which I could braze onto the end of the shaft, I closed the existing cross hole by brazing a bolt into it, drilled a new cross hole, and machined the shaft on my lathe to get an even surface again.

Now my build had reached an important step. I had mounted all metal sheet parts and they fitted together. So it is time to take everything apart again and start painting and lining. The wheels will be the first candidates. The painting will be done in a small cabinet behind our garage. This room cannot be heated, so I have to wait for Summer-temperatures. In the meantime I will receive the final kits no. 20 through 24, and I will start to design and make the adequate templates for the lining.

Valve Gear:

I was really looking forward to complete the arrangement of rods and levers between crankshaft and cylinder. But soon I had to experience a real shock: I found out, there was not enough room for one of the eccentric straps. After some filing I was able to fit the eccentric strap for the reverse eccentric. But there was by far not enough space for the forward eccentric strap. The clearance between steam head pipe and eccentric was 3,5 mm only. I needed approximately 5 millimeters more.

So, what could I do:

My first thought was to make some changes to the steam elbow and the counter nut, and to file down the boiler bush where the steam elbow goes into. But I do not think this would be the right way. Probably a better way would be to set the boiler somewhat deeper between the hornplates, 5 mm deeper. That would mean to take everything apart and change the fastener holes in the hornplates into long slots. You know me already: I hate slots, therefore I would close the holes, 7 holes on each side, by brazing adequate steel pieces into them and then drill new holes.

What do the experts from STW think about it?

I would like to know,what is the accurate reference distance between the top of the boiler and the centre of the crankshaft. Can I get those answers within this forum or shall I better write an e-mail to STW?

It is already three days ago, when I found out about this problem. In the first moment I thought, what a catastrophe! In the meantime i became pretty calm. It is no catastrophe at all. I can repair the problem easily and perfectly with my own workshop equipment. And I have to take apart my machine anyway for painting. So it is only the additional labour to make the new holes in the hornplates. But I need the input from STW to get the right dimensions.

And I need some informations for making new steam pipes between the two steam elbows (BU 21229) and the steam head, and the upper water gauge set respectively. Today I had a look into the homepage of www.maidstone-engineering, where I can get copper pipe, union cones and union nuts. But I am not familiar enough with the British standards. So I should like to ask STW, which dimensions I would need. I have very good experiences to make copper pipes with bends, even with threedimensional bends. I know how to get them exactly to the point.

Before starting to put these parts together it is better to wait for kit no. 16B, where the water gauge set is included. To get a better access to the top of the boiler I removed the crankshaft and the RH crankshaft bearing.

In a first step I mounted the upper part of the water gauge set to the water gauge bracket (see boiler BU 21227), and the lower part of the water gauge set to the lower water gauge extension (see boiler BU 21228) together with their 3/8"x32 lock nuts. The water gauge setting rod (BU 21624) helps to get the upper and the lower part in line. In my case I had to shorten the lower water gauge extension by a few millimeters.

In the next step I tried to fix the water gauge pipe (BU 21623). It did not fit and it was very, very difficult to make it's ends to match between the steam elbow and the upper part of the water gauge set. It is extremly hard to change the bending angles of a short pipe like this. Furthermore there is no chance to adjust the final length of the pipe, because it already had it's fittings at both ends. I was really afraid that I would fail. But to my upmost surprise, after several attempts I made it. Dem Ingenioer ist nichts zu schwoer - there is nothing too difficult for an engineer.

After doing this I attached the steam head with it's valves. Read the instructions carefully to get them in the right direction. With the steam head pipe I had the same problems. It was only a little bit easier insofar as the two bends of the pipe are in the same level. In the end both pipes looked pretty dented. I can only hope that I did not damage the fittings at their ends. Will they be tight enough under steam pressure? If not, I will have to fabricate new pipes, following my own well proven method using union cones, which can be brazed into the ends of the pipes.

A completely different problem was to get the RH crankshaft bearing back. How do I get the nuts and washers to their positions without dropping them. This is my trick:

I put some grease on my fingertip. The photo below shows how a small nut sticks pretty reliably, even when you transport it together with it's washer.

Weighshaft bracket:

After a short time of studying the situation I became aware that the bore for the main valve rod must be the reference point for setting and aligning the weighshaft bracket.

The weighshaft bracket shim (BU 21131) turned out to be too thick. I had to file it down from 2 mm to approximately 1,5 mm. And I had to change the holes in the baseplate of the weighshaft bracket into short slots. After this the main valve rod (BU 21916) could be pushed easily through the Iglidur bushes (BU 21916).

The bottom slide bar for the cross head could be fixed to the weighshaft bracket without any rework. The top slide bar (BU 21117) turned out to be too tight. Therefore I milled off approximately 0,2 mm.

Putting together the parts for the connecting rod made me no problems. But I did not like the long wedge (BU 21612). So I did not use it, and I shortened the long wedge bolt. As I already mentioned before, my Burrel will run under steam for a short time only, after this it will serve as a show piece.

Flywheel:

What a beautiful piece of equipment, I really like it. Therfore I did not understand the instructions which recommend to remove the casting skin. Why that? Nobody did that with the original. For the painting it would not make any difference. But I followed the instruction and filed two small flats into the crankshaft for the grub screws.

It was a great moment to turn the flywheel the first moment and to see how crankshaft, connecting rod, crosshead and piston rod work together smoothly.

Crankshaft gear guard:

There is a note in the instructions: One of the hexheads of the fasteners has to stay on the outside of the tender wall. You cannot get access to it after assembly of the differential. Therefore I made a special fastener which I could glue onto the outside of the tender wall using 2K-epoxy adhesive.

Differential and 2nd shaft gears:

In the forum I did not read about any problems to get the 1st & 2nd gear on the spline of the crankshaft. I had a problem: It took me several hours of nervy filing before I was able to slide these two small pinions onto the spline. Finally I added some grease, now I can easily slide them without any significant shake.

Also the other parts needed quite a bit of handwork to fit them together. Especially the four prongs of the differential locking ring did not fit into the slots of the inside bevel gear (BU 21701).

In the end I found out that the 2nd shaft is a little bit too short. Not a big problem, I solved it by making a new RH main spur gear washer (BU 21723).

After assembling everything I could still rotate the flywheel as freely as before. But the differential did not work, I could not move it at all. The bevel gears and bevel pinions blocked each other. My first thought was: Leave it as it is, the working of the differential is not essential for the final build. But this is not the way my mind works.

On the next day I removed the crank gear guard once more and took apart the differential. I made a new outside bevel thrust washer (BU 21713), 3,5 mm thick instead of 2,5 mm.

With this change the compensation centre (BU 21704) has got some axial clearance. It is much better now, but it still does not move really smoothly. The teeth of the bevels and the bevel pinions are probably not made precisely enough. Should they? I am not sure. Therefore I ask the other Burrel owners, did you make similiar experiences?

Final Drive and Winch:

I had no problems with the final drive gears. They fitted without any reworking.

Gear Guards:

The gear guards needed some filing to remove sharp edges. The LH gear guard fitted perfectly. For the RH gear guard I had to make washers with 2 mm, 3 mm and 4 mm thickness. Otherwise the gear wheels would have grazed the guards making nasty noises.

One of the fasteners (the one where the 4 mm washer was needed) would have had it's nut inside the water tank. I did not want to open this tank after I had sealed it's walls with liquid rubber. For this reason I provided this washer with a M3 tap and fixed it to the outside of the tender using 2K-epoxy adhesive.

Wheel retaining collars for the rear wheels:

On the RH side the wheel retaining collar did not fit. The rear shaft was too short by about 2,5 mm. Therefore I shortened the RH final drive spacer (BU 21816) by 2,5 mm. Only to find out that this was definitely the wrong way to solve the problem. So I made a new washer to get the RH final drive spacer back to it's original length. A better way to solve the problem would have been taking 2,5 mm off from the final drive gear. But I did not like this idea. I decided instead to make the rear wheel shaft longer by approximately 2,8 mm. The shaft has 19 mm diameter. Therefor I made a short piece of steel with 20mm diameter with a 19 mm diameter collar 2 mm deep, which I could braze onto the end of the shaft, I closed the existing cross hole by brazing a bolt into it, drilled a new cross hole, and machined the shaft on my lathe to get an even surface again.

Now my build had reached an important step. I had mounted all metal sheet parts and they fitted together. So it is time to take everything apart again and start painting and lining. The wheels will be the first candidates. The painting will be done in a small cabinet behind our garage. This room cannot be heated, so I have to wait for Summer-temperatures. In the meantime I will receive the final kits no. 20 through 24, and I will start to design and make the adequate templates for the lining.

Valve Gear:

I was really looking forward to complete the arrangement of rods and levers between crankshaft and cylinder. But soon I had to experience a real shock: I found out, there was not enough room for one of the eccentric straps. After some filing I was able to fit the eccentric strap for the reverse eccentric. But there was by far not enough space for the forward eccentric strap. The clearance between steam head pipe and eccentric was 3,5 mm only. I needed approximately 5 millimeters more.

So, what could I do:

My first thought was to make some changes to the steam elbow and the counter nut, and to file down the boiler bush where the steam elbow goes into. But I do not think this would be the right way. Probably a better way would be to set the boiler somewhat deeper between the hornplates, 5 mm deeper. That would mean to take everything apart and change the fastener holes in the hornplates into long slots. You know me already: I hate slots, therefore I would close the holes, 7 holes on each side, by brazing adequate steel pieces into them and then drill new holes.

What do the experts from STW think about it?

I would like to know,what is the accurate reference distance between the top of the boiler and the centre of the crankshaft. Can I get those answers within this forum or shall I better write an e-mail to STW?

It is already three days ago, when I found out about this problem. In the first moment I thought, what a catastrophe! In the meantime i became pretty calm. It is no catastrophe at all. I can repair the problem easily and perfectly with my own workshop equipment. And I have to take apart my machine anyway for painting. So it is only the additional labour to make the new holes in the hornplates. But I need the input from STW to get the right dimensions.

And I need some informations for making new steam pipes between the two steam elbows (BU 21229) and the steam head, and the upper water gauge set respectively. Today I had a look into the homepage of www.maidstone-engineering, where I can get copper pipe, union cones and union nuts. But I am not familiar enough with the British standards. So I should like to ask STW, which dimensions I would need. I have very good experiences to make copper pipes with bends, even with threedimensional bends. I know how to get them exactly to the point.

karl heinz marschner- Number of posts : 33

Location : Duesseldorf, Germany

Registration date : 2021-04-13

Re: Putting together a Burrel in Duesseldorf

Re: Putting together a Burrel in Duesseldorf

Hi Karl

For your dimensional measurements you should probably Email Lynn at.

support@steamtractionworld.co.uk

As to the elbow on the top of the boiler 2 things spring to mind.

Firstly can you tighten the pipe nut so that the flat is at the point the eccentric passes over it.

Second option as you have a lathe is to thin the elbow locking nut, would be to thin the nut by 1 or 2 thread pitches to allow the elbow to screw further into the boiler boss.

Less work than brazing up and re-drilling all those holes.

Loving your work and the fixes you are coming up with.

Keep up the good work.

Simon C

For your dimensional measurements you should probably Email Lynn at.

support@steamtractionworld.co.uk

As to the elbow on the top of the boiler 2 things spring to mind.

Firstly can you tighten the pipe nut so that the flat is at the point the eccentric passes over it.

Second option as you have a lathe is to thin the elbow locking nut, would be to thin the nut by 1 or 2 thread pitches to allow the elbow to screw further into the boiler boss.

Less work than brazing up and re-drilling all those holes.

Loving your work and the fixes you are coming up with.

Keep up the good work.

Simon C

Simon C- Number of posts : 303

Location : Derby

Registration date : 2017-07-07

karl heinz marschner likes this post

Re: Putting together a Burrel in Duesseldorf

Re: Putting together a Burrel in Duesseldorf

Hello Simon,

thank you for your recommendations. I had already thought about the possibilities you told me. I do not think, I would gain enough space by doing this. As you recommend I will write an e-mail to Lynn.

Best regards

Karl Heinz

thank you for your recommendations. I had already thought about the possibilities you told me. I do not think, I would gain enough space by doing this. As you recommend I will write an e-mail to Lynn.

Best regards

Karl Heinz

karl heinz marschner- Number of posts : 33

Location : Duesseldorf, Germany

Registration date : 2021-04-13

Re: Putting together a Burrel in Duesseldorf

Re: Putting together a Burrel in Duesseldorf

Hi

If you have a thread die you can extend the threads on the section that goes in to the boiler. This will reduce the over all height with out issue. Another choice is either thin or remove the lock nut again this will reduce the overall height.

If you have a thread die you can extend the threads on the section that goes in to the boiler. This will reduce the over all height with out issue. Another choice is either thin or remove the lock nut again this will reduce the overall height.

_________________

Lynn

Technical Support

Steam Traction World Ltd

Re: Putting together a Burrel in Duesseldorf

Re: Putting together a Burrel in Duesseldorf

Problem solved successfully:

In the meantime the problem could be solved perfectly. I had written an E-Mail to Lynn and got this answer from her: The correct distance between the top of the boiler and the bottom of the bearing housing (i.e. bottom of hornplate-alignment tool) is 36,5 mm. I checked this immediately and found out, my boiler sits perfectly, no need for any change in position.

My recommendation for the STW-instructions: This distance should be included in drawing ISO BU212 sheet 5 of 5

Furthermore Lynn took care for getting me new steam elbows with longer threads. A few days later I got them from Rosemary. I was still doubtful: The longer thread would allow for 3 mm more space only. But to my surprise, after installing the new steam elbows I was able to mount the eccentric straps (BU21909) without any difficulty, the whole mechanism is moving freely.

Once more: Many thanks to Lynn and Rosemary for their friendly help.

Now I am working on Kit no. 20 - Regulator & Reverser, and ran into a new problem. I have to ask Lynn once more. I will be back after solving this problem.

In the meantime the problem could be solved perfectly. I had written an E-Mail to Lynn and got this answer from her: The correct distance between the top of the boiler and the bottom of the bearing housing (i.e. bottom of hornplate-alignment tool) is 36,5 mm. I checked this immediately and found out, my boiler sits perfectly, no need for any change in position.

My recommendation for the STW-instructions: This distance should be included in drawing ISO BU212 sheet 5 of 5

Furthermore Lynn took care for getting me new steam elbows with longer threads. A few days later I got them from Rosemary. I was still doubtful: The longer thread would allow for 3 mm more space only. But to my surprise, after installing the new steam elbows I was able to mount the eccentric straps (BU21909) without any difficulty, the whole mechanism is moving freely.

Once more: Many thanks to Lynn and Rosemary for their friendly help.

Now I am working on Kit no. 20 - Regulator & Reverser, and ran into a new problem. I have to ask Lynn once more. I will be back after solving this problem.

karl heinz marschner- Number of posts : 33

Location : Duesseldorf, Germany

Registration date : 2021-04-13

Back in the forum, at last

Back in the forum, at last

Back in the forum, at last

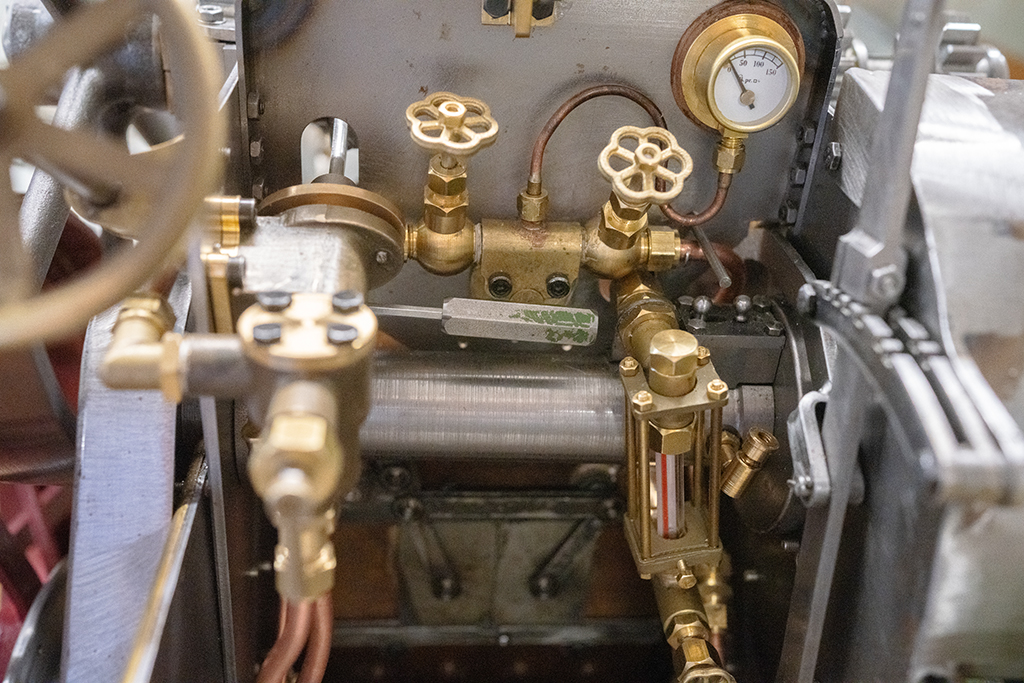

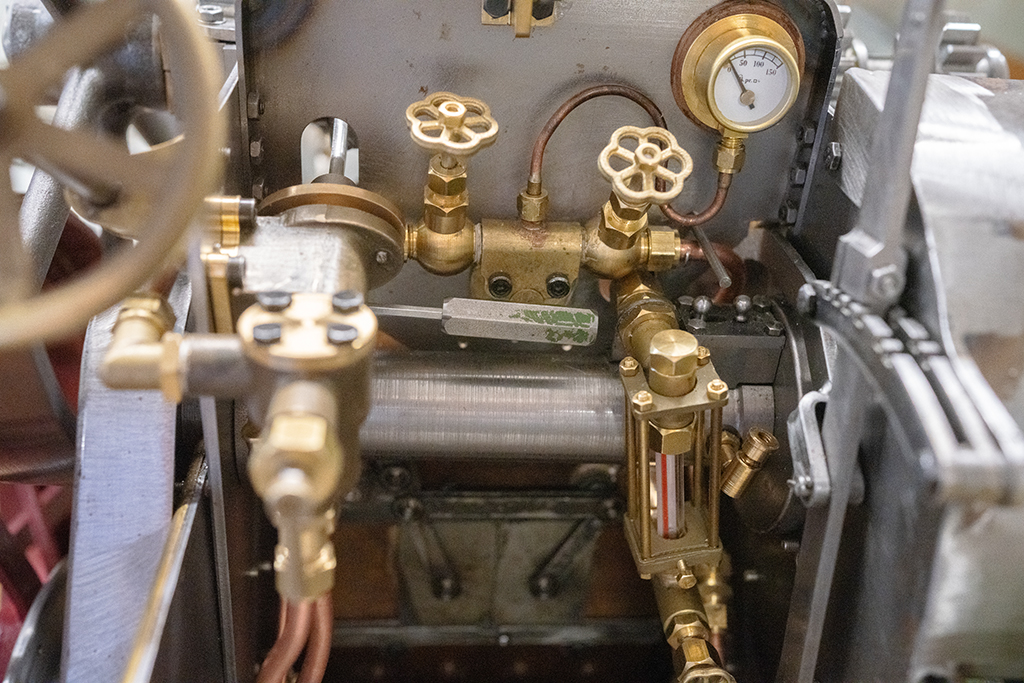

My last post has been from July last year. In the meantime I have machined a number of parts for my other project, the 2 inch Shand Mason. I have started with painting and lining the wheels. I will tell you about my experiences in a separate thread. And I have accomplished kit no. 20 - Regulator & Reverser, kit no. 21 - water pump etc., kit no. 22A - Water Gauge & Parking Brake, and kit no. 23 - Lubricator etc.

I am still waiting for the last two kits no. 22B and no. 24.

My last post has been from July last year. In the meantime I have machined a number of parts for my other project, the 2 inch Shand Mason. I have started with painting and lining the wheels. I will tell you about my experiences in a separate thread. And I have accomplished kit no. 20 - Regulator & Reverser, kit no. 21 - water pump etc., kit no. 22A - Water Gauge & Parking Brake, and kit no. 23 - Lubricator etc.

I am still waiting for the last two kits no. 22B and no. 24.

Last edited by karl heinz marschner on Mon 04 Mar 2024, 8:39 pm; edited 1 time in total

karl heinz marschner- Number of posts : 33

Location : Duesseldorf, Germany

Registration date : 2021-04-13

Re: Putting together a Burrel in Duesseldorf

Re: Putting together a Burrel in Duesseldorf

Kit no. 20 - Regulator & Reverser, Exhaust & Blower

In my last post I had mentioned some difficulties with the thread of the Blower Adapter BU22050. Lynn helped me by telling me the thread size, and she recommended me a UK-source for ME thread cutting tools. So I got a whole set from Tracy Tools:

1/4"x40 - 7/32"x40 - 3/16"x40 and 3/8"x32 - 5/16"x32

Now I am prepared for further problems. And I have started to understand the mysteries of the numerous UK-standards for making threads. Did I solve the problem with the Blower Adapter? Yes I did, I recut the thread, but still couldn't get the adapter into the cylinder block. The culprit was not the thread, it was the lowermost fastener for the cylinder cladding, which was too long and generated an obstacle. Shit happens.

Exhaust Pipe BU22009 and Blast Pipe BU22012

It is better to install these parts first before installing the Blower Pipe. I removed the chimney from the chimney base and attached enough PTFE-tape to the thread at the end of the Blast Pipe. I used a gripping plier to hold the Blast Nozzle while screwing the Blast Pipe into it. The PTFE-tape takes care that the Blast Nozzle remains in its upright position.

Fixing the flange of the Exhaust Pipe to the Cylinder Block was a nightmare. It seemed almost impossible to get the LH fastener nut (seen from the front) to its place. But as I already mentioned, dem Ingenioer ist nichts zu schwoer - there is nothing too difficult for an engineer. This was my method:

- I removed the front cylinder cover and its lower skt grub screws, to get more room for a spanner.

- Filed some material away from the pipe to get some more space for the LH fastener nut.

- I did not use the standard M3 nuts. I used so called M3 nuts for model workers with 4 mm AF only. Those nuts and fasteners I get from this company:

Dieter Knupfer

Modell und Feinwerktechnik

Ellenbergweg 3

73614 Schorndorf

Germany

www.knupfer.info

I asked them, they regularly supply their parts to the UK.

- I put the nut onto the M3 skt grub screw before driving it into the cylinder block by using an Allen key, where I had cut something off to make the short end even

shorter.

This photo shows the difference in size. The small wrench for 4 mm AF is also from Dieter Knupfer.

To bring the two flanges (exhaust pipe / blast pipe) together was not difficult. Gently hitting the copper pipe using a small hammer and a piece of wood.

Blower Pipe BU22051

The blower pipe has approximately 3,3 mm Diameter. The hole in the chimney base is not any bigger. The only way to get it done is to push the straight pipe through this hole, and then try to bend its end upwards. But is this really the right method? I found a tip in one of the older posts from Lynn: A ring spanner is an adequate tool for bending this pipe inside the chimney base.

Regulator & Reverser

Some of the holes were too tight for the according pins. I had to redrill the holes. Doing this I always prefer to use my milling machine, where I can take care for the best conditions for precise results.

I polished the handles of the Regulator Lever and of the Reverser Lever, they will get nickel plated before final assembly. The spring angle BU22028 was the tiniest piece of equipment I ever put together. After threading in the 1 mm - rivets I secured them with instant adhesive, which is a good method to prevent loosing those very small parts. After that I did the peening.

The extension-spring for the Reversing Trigger is too weak, I think. So I will try to get a stronger one from the above mentioned German supplier Dieter Knupfer.

For threading the Reach Rod BU22007 through the rear spectacle plate I had to dismantle the Differential Locking Plate BU21719. And I found out that the Reach Rod collided with the rear spectacle plate. I was able to take care for this by filing some material away without taking apart everything. But the Reach Rod also collided slightly with the RH Camshaft Bearing Housing. So I made another note to my list "Things to do before final assembly".

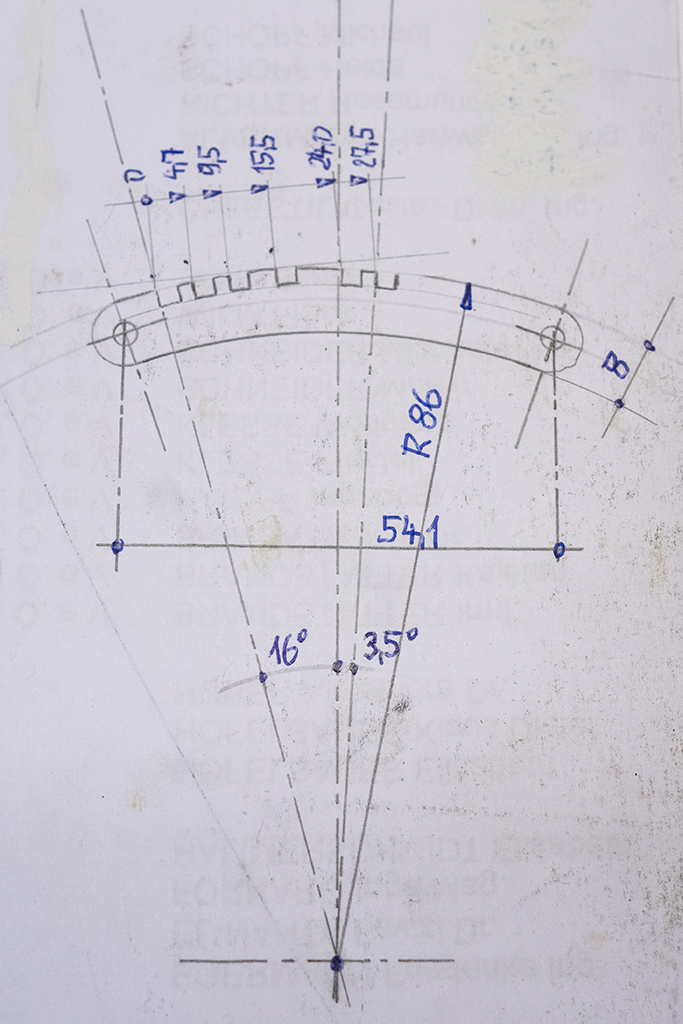

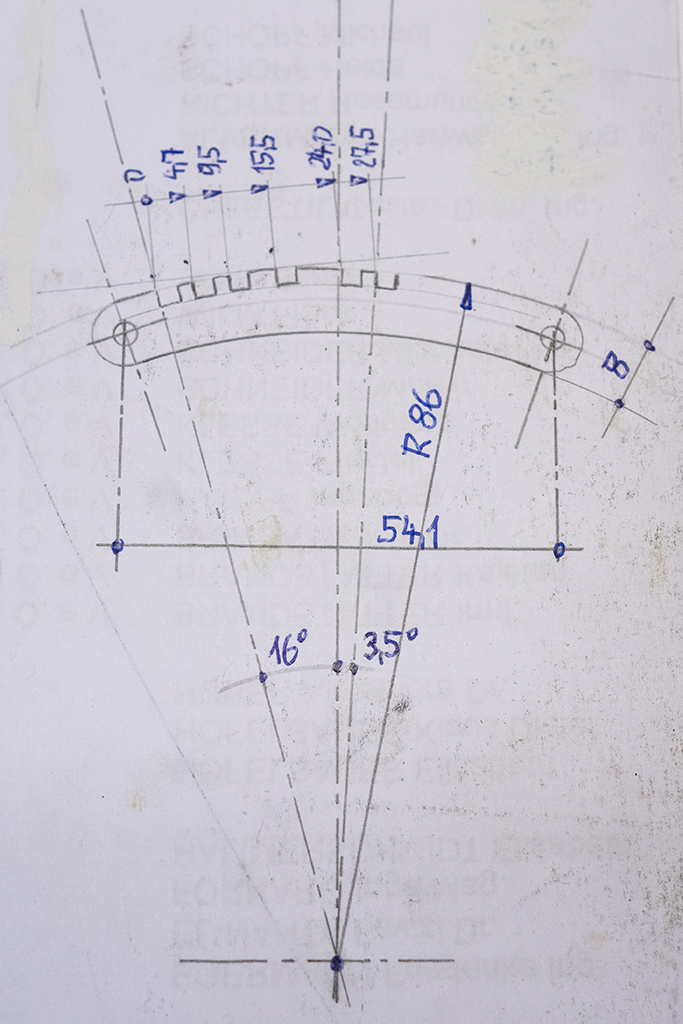

Finishing the two Reversing Quadrants BU22034

I followed the instructions to find out the positions of the Reversing Lever in full forward and full reverse. I marked these positions on the Reversing Quadrant. Then I made me a drawing of the Reversing Quadrant with all dimensions:

width of slots . . . . . 2,7 mm

depth of slots . . . . . 2,0 mm

And I made a fixture for machining the slots on my milling machine.

In my last post I had mentioned some difficulties with the thread of the Blower Adapter BU22050. Lynn helped me by telling me the thread size, and she recommended me a UK-source for ME thread cutting tools. So I got a whole set from Tracy Tools:

1/4"x40 - 7/32"x40 - 3/16"x40 and 3/8"x32 - 5/16"x32

Now I am prepared for further problems. And I have started to understand the mysteries of the numerous UK-standards for making threads. Did I solve the problem with the Blower Adapter? Yes I did, I recut the thread, but still couldn't get the adapter into the cylinder block. The culprit was not the thread, it was the lowermost fastener for the cylinder cladding, which was too long and generated an obstacle. Shit happens.

Exhaust Pipe BU22009 and Blast Pipe BU22012

It is better to install these parts first before installing the Blower Pipe. I removed the chimney from the chimney base and attached enough PTFE-tape to the thread at the end of the Blast Pipe. I used a gripping plier to hold the Blast Nozzle while screwing the Blast Pipe into it. The PTFE-tape takes care that the Blast Nozzle remains in its upright position.

Fixing the flange of the Exhaust Pipe to the Cylinder Block was a nightmare. It seemed almost impossible to get the LH fastener nut (seen from the front) to its place. But as I already mentioned, dem Ingenioer ist nichts zu schwoer - there is nothing too difficult for an engineer. This was my method:

- I removed the front cylinder cover and its lower skt grub screws, to get more room for a spanner.

- Filed some material away from the pipe to get some more space for the LH fastener nut.

- I did not use the standard M3 nuts. I used so called M3 nuts for model workers with 4 mm AF only. Those nuts and fasteners I get from this company:

Dieter Knupfer

Modell und Feinwerktechnik

Ellenbergweg 3

73614 Schorndorf

Germany

www.knupfer.info

I asked them, they regularly supply their parts to the UK.

- I put the nut onto the M3 skt grub screw before driving it into the cylinder block by using an Allen key, where I had cut something off to make the short end even

shorter.

This photo shows the difference in size. The small wrench for 4 mm AF is also from Dieter Knupfer.

To bring the two flanges (exhaust pipe / blast pipe) together was not difficult. Gently hitting the copper pipe using a small hammer and a piece of wood.

Blower Pipe BU22051

The blower pipe has approximately 3,3 mm Diameter. The hole in the chimney base is not any bigger. The only way to get it done is to push the straight pipe through this hole, and then try to bend its end upwards. But is this really the right method? I found a tip in one of the older posts from Lynn: A ring spanner is an adequate tool for bending this pipe inside the chimney base.

Regulator & Reverser

Some of the holes were too tight for the according pins. I had to redrill the holes. Doing this I always prefer to use my milling machine, where I can take care for the best conditions for precise results.

I polished the handles of the Regulator Lever and of the Reverser Lever, they will get nickel plated before final assembly. The spring angle BU22028 was the tiniest piece of equipment I ever put together. After threading in the 1 mm - rivets I secured them with instant adhesive, which is a good method to prevent loosing those very small parts. After that I did the peening.

The extension-spring for the Reversing Trigger is too weak, I think. So I will try to get a stronger one from the above mentioned German supplier Dieter Knupfer.

For threading the Reach Rod BU22007 through the rear spectacle plate I had to dismantle the Differential Locking Plate BU21719. And I found out that the Reach Rod collided with the rear spectacle plate. I was able to take care for this by filing some material away without taking apart everything. But the Reach Rod also collided slightly with the RH Camshaft Bearing Housing. So I made another note to my list "Things to do before final assembly".

Finishing the two Reversing Quadrants BU22034

I followed the instructions to find out the positions of the Reversing Lever in full forward and full reverse. I marked these positions on the Reversing Quadrant. Then I made me a drawing of the Reversing Quadrant with all dimensions:

width of slots . . . . . 2,7 mm

depth of slots . . . . . 2,0 mm

And I made a fixture for machining the slots on my milling machine.

Last edited by karl heinz marschner on Mon 04 Mar 2024, 9:04 pm; edited 3 times in total

karl heinz marschner- Number of posts : 33

Location : Duesseldorf, Germany

Registration date : 2021-04-13

Re: Putting together a Burrel in Duesseldorf

Re: Putting together a Burrel in Duesseldorf

Setting up the steering mechanism - Valve timing

Now I have to make a confession: The Burrel is my first steam engine with valve gear. So I had to make sure to fully understand this mechanism. I digged out my old books from the technical university to commemorate, what I had learned 60 years ago. And I made me schematic drawings of the cylinder and the steam chest of my Burrel.

I followed the instructions to set up the steering mechanism, and found out, that it was not possibel to realize a symmetrical movement of the slide valve & buckle inside the steam chest. The locking nut, which secures the Valve Rod BU21114 to the valve buckle BU21112 hits the side wall of the steam chest. So I had to take off some material from the Valve Buckle.

Heat Expansion

In the instructions you get pointed to the heat expansion, which may generate a problem for the valve timing. I made a calculation to find out, wether it is really dramatic or not.

Ambient temperature . . . . . . . . . . . . . . . . . . . . . . . . . . Ta = 20° C

Temperature of boiler at 100 psi . . . .. . . . . . . . . . . . . . . Tb = 165° C

Temperature of steering mechanism . . . . . . . . . . . . . . . . Ts = 50° C

Distance between crankshaft and center of steamchest . . . L = 280 mm

Coefficient of thermal expansion for steel . . . . . . . . . . . . as = 11,1 / 1000000 mm/mm.grd

Coefficient of thermal expansion for copper . . . . . . . . . . . ac = 16,2 / 1000000 mm/mm.grd

Expansion of steering mechanism . . . . . . . . . . . . . . . . . . delta Ls = L.as.(Ts - Ta)/1000000 = 0,09 mm

Expansion of boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . .delta Lb = L.ac.(Tb - Ta)/1000000 = 0,66 mm

These expansion-figures have to be compared with the stroke of excentric, which is 8,8 mm

Now I have to make a confession: The Burrel is my first steam engine with valve gear. So I had to make sure to fully understand this mechanism. I digged out my old books from the technical university to commemorate, what I had learned 60 years ago. And I made me schematic drawings of the cylinder and the steam chest of my Burrel.

I followed the instructions to set up the steering mechanism, and found out, that it was not possibel to realize a symmetrical movement of the slide valve & buckle inside the steam chest. The locking nut, which secures the Valve Rod BU21114 to the valve buckle BU21112 hits the side wall of the steam chest. So I had to take off some material from the Valve Buckle.

Heat Expansion

In the instructions you get pointed to the heat expansion, which may generate a problem for the valve timing. I made a calculation to find out, wether it is really dramatic or not.

Ambient temperature . . . . . . . . . . . . . . . . . . . . . . . . . . Ta = 20° C

Temperature of boiler at 100 psi . . . .. . . . . . . . . . . . . . . Tb = 165° C

Temperature of steering mechanism . . . . . . . . . . . . . . . . Ts = 50° C

Distance between crankshaft and center of steamchest . . . L = 280 mm

Coefficient of thermal expansion for steel . . . . . . . . . . . . as = 11,1 / 1000000 mm/mm.grd

Coefficient of thermal expansion for copper . . . . . . . . . . . ac = 16,2 / 1000000 mm/mm.grd

Expansion of steering mechanism . . . . . . . . . . . . . . . . . . delta Ls = L.as.(Ts - Ta)/1000000 = 0,09 mm

Expansion of boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . .delta Lb = L.ac.(Tb - Ta)/1000000 = 0,66 mm

These expansion-figures have to be compared with the stroke of excentric, which is 8,8 mm

karl heinz marschner- Number of posts : 33

Location : Duesseldorf, Germany

Registration date : 2021-04-13

Re: Putting together a Burrel in Duesseldorf

Re: Putting together a Burrel in Duesseldorf

Preparing for the first running on compressed air

In the instructions for kit no.21 I found a recommendation to run the machine with compressed air. So far I had not taken this into mind, my line of thought was, to complete everything, then take apart everything for painting, then put everything together again, test it with compressed air first, and finally heat it up and put it into operation with steam.

But now I changed my mind. I will follow the recommendation to run the beast with compressed air as soon as possible. A long time ago I had sealed the tender with liquid rubber. But so far I had not taken any care for the tightness of the boiler and its fittings. So I had to do this now, and this turned out to be one hell of a job.

- To tighten threads I used PTFE-tape

- To tighten flanges I used MARSTON-Universal Jointing Compound, which should be appropriate for temperatures up until 270° C.

To get access to the fusible plug on top inside the fire-box I had to set the whole machine on one side. This was quite a big thing for me, because I am used to work alone. To get access to the tube plate plug inside the smoke box I had to shorten the top fastener connecting the boiler with the smoke box. This in turn I could only do after dismantling the exhaust blast pipe.

And I had to dismantle the complete valve gear, the crankshaft and the RH crankshaft bearing, and the slide bars for the cross head. And I took the piston out from the cylinder.

It was very, very nervy, but now I was able to tighten the two steam elbows on top outside the firebox, and I was able to use graphited yarn for the gland packings for the piston rod, regulator rod and the slide valve rod.

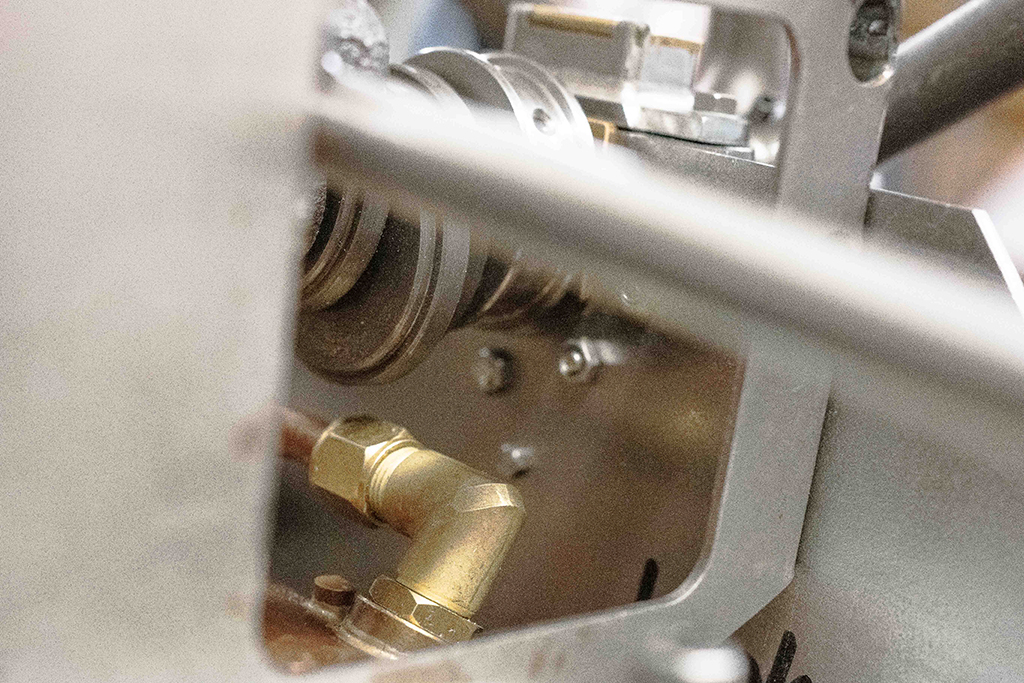

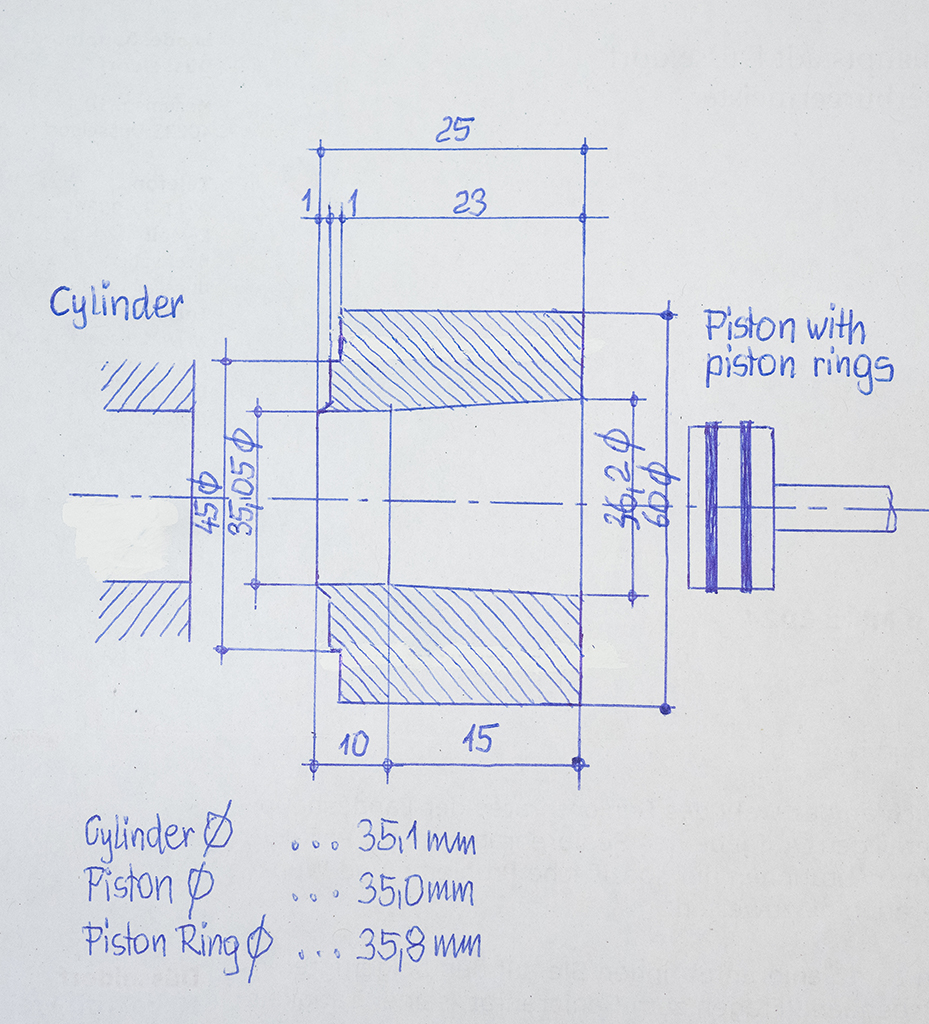

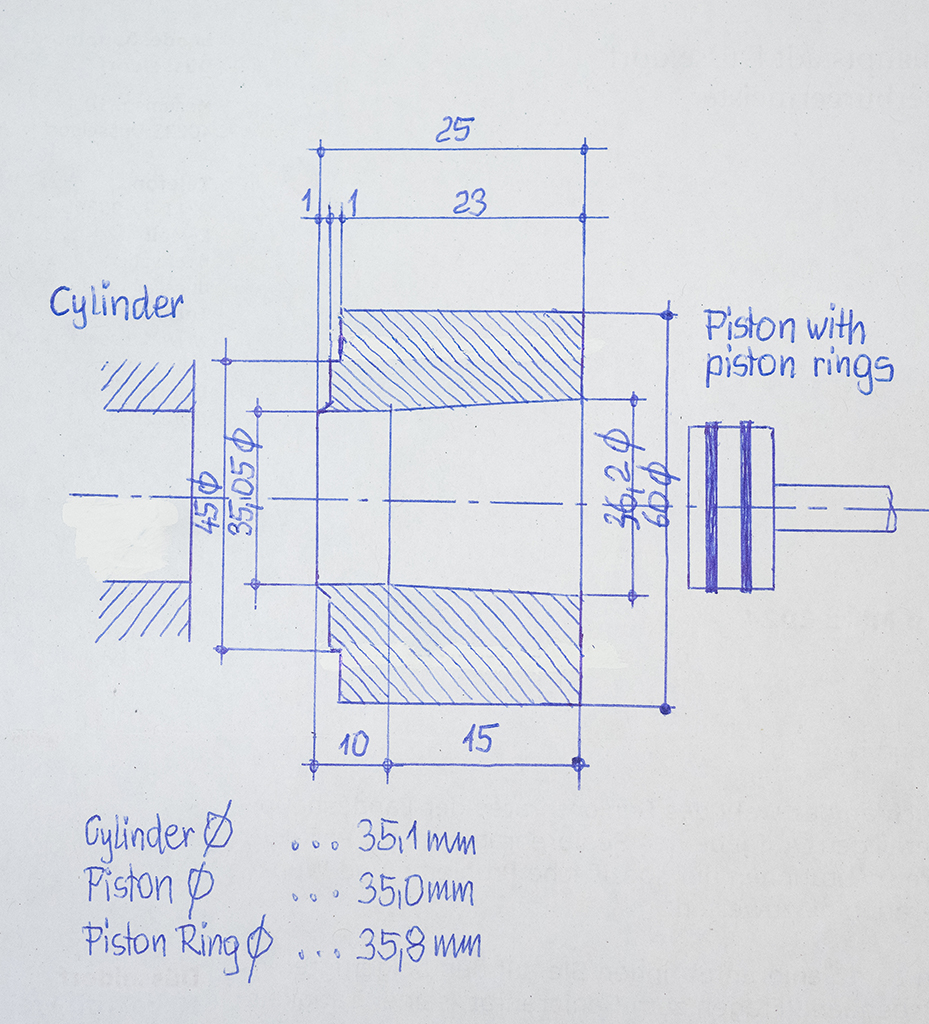

To get the piston with the piston-rings back into the cylinder I had made me a special device, which now turned out to be very practical:

The photo shows that this device is made in two parts. So it is not necessary to take the assembly of piston/piston-rod/cylinder-cover/crosshead apart. I had already secured the ends of the piston rod with Loctite and did not want to take the assembly apart once more.

In the instructions for kit no.21 I found a recommendation to run the machine with compressed air. So far I had not taken this into mind, my line of thought was, to complete everything, then take apart everything for painting, then put everything together again, test it with compressed air first, and finally heat it up and put it into operation with steam.

But now I changed my mind. I will follow the recommendation to run the beast with compressed air as soon as possible. A long time ago I had sealed the tender with liquid rubber. But so far I had not taken any care for the tightness of the boiler and its fittings. So I had to do this now, and this turned out to be one hell of a job.

- To tighten threads I used PTFE-tape

- To tighten flanges I used MARSTON-Universal Jointing Compound, which should be appropriate for temperatures up until 270° C.

To get access to the fusible plug on top inside the fire-box I had to set the whole machine on one side. This was quite a big thing for me, because I am used to work alone. To get access to the tube plate plug inside the smoke box I had to shorten the top fastener connecting the boiler with the smoke box. This in turn I could only do after dismantling the exhaust blast pipe.

And I had to dismantle the complete valve gear, the crankshaft and the RH crankshaft bearing, and the slide bars for the cross head. And I took the piston out from the cylinder.

It was very, very nervy, but now I was able to tighten the two steam elbows on top outside the firebox, and I was able to use graphited yarn for the gland packings for the piston rod, regulator rod and the slide valve rod.

To get the piston with the piston-rings back into the cylinder I had made me a special device, which now turned out to be very practical:

The photo shows that this device is made in two parts. So it is not necessary to take the assembly of piston/piston-rod/cylinder-cover/crosshead apart. I had already secured the ends of the piston rod with Loctite and did not want to take the assembly apart once more.

karl heinz marschner- Number of posts : 33

Location : Duesseldorf, Germany

Registration date : 2021-04-13

Re: Putting together a Burrel in Duesseldorf

Re: Putting together a Burrel in Duesseldorf

Improving the function of the differential

In one of my previous posts I had told, that I was not very comfortable with the working of the differential. It did not move smoothly, but blocked regularly. When mounting the Reach Rod Lever it was necessary to take off the Crankshaft Gear Guard BU21817. This was a good opportunity to have another look to the differential. I suspected that the problems had to do with slackness between the various parts. Not enough clearance? Or even too much clearance?

The Outside Bevel Gear Thrust Washer BU21713 did not look very good. Its thickness varied between 2,6 - 3,15 mm, the inner diameter was too large. To understand the situation I did some measurements and made me a drawing with all critical dimensions.

Finally I made a new Outside Bevel Thrust Washer and a new RH Main Spur Gear Washer. The result: The Differential is now moving smoothly, the two Rear Wheels can be moved freely and independantly.

Kit No. 21 - Water Pump, Check Valves, Blow Down Valve, Pressure Gauge, Pipe Work

This kit turned out to be so far the most difficult one.

Blow Down Valve BU22152

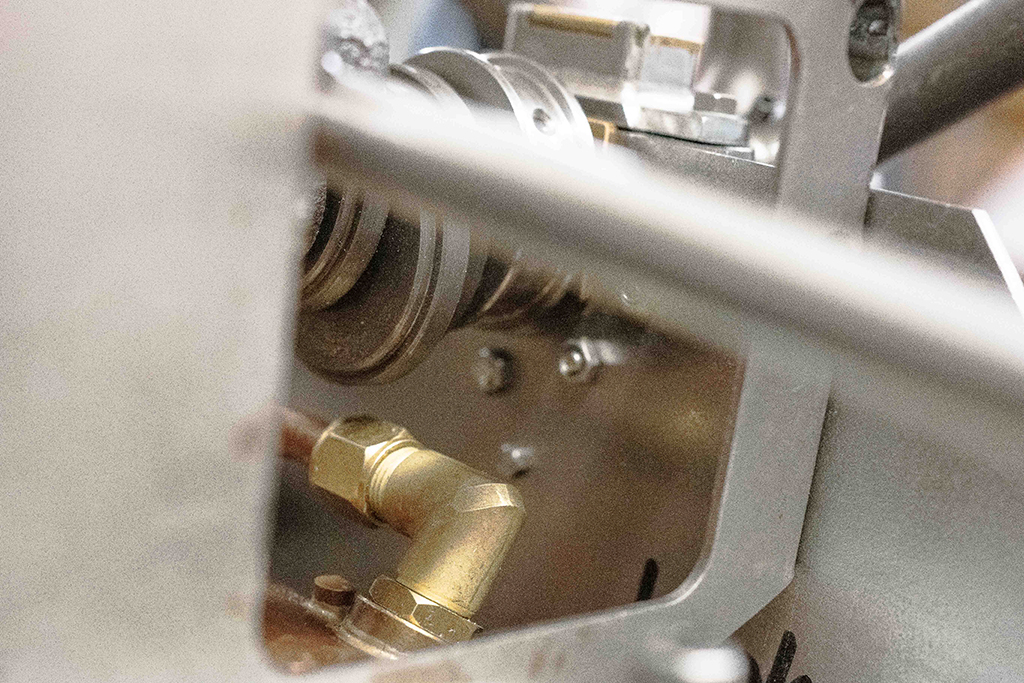

That was pretty easy. The photo below shows how it looks after filing off the edges from the Washer BU2216

Water Lifter Pipes BU22163 & 64

These pipes are mentioned at the end of the instructions. But it is essential that they get assembled before installing the Water Pump. Otherwise it wouldn't be possible to fix the union nut to the globe valve at the lefthand side of the steamhead.

Recommendation to STW: Put this part of the instruction to the beginning.

Fastening the Double Pipe Union 001145 just in front of the Tender Tank was a problem. Standard wrenches are too long for this operation, the space for moving them is very limited. I had to cut two of them into parts.

In the photo you can see that i took some materia off from the end of the 3/8-inch wrench to get more space for movement.

In one of my previous posts I had told, that I was not very comfortable with the working of the differential. It did not move smoothly, but blocked regularly. When mounting the Reach Rod Lever it was necessary to take off the Crankshaft Gear Guard BU21817. This was a good opportunity to have another look to the differential. I suspected that the problems had to do with slackness between the various parts. Not enough clearance? Or even too much clearance?

The Outside Bevel Gear Thrust Washer BU21713 did not look very good. Its thickness varied between 2,6 - 3,15 mm, the inner diameter was too large. To understand the situation I did some measurements and made me a drawing with all critical dimensions.

Finally I made a new Outside Bevel Thrust Washer and a new RH Main Spur Gear Washer. The result: The Differential is now moving smoothly, the two Rear Wheels can be moved freely and independantly.

Kit No. 21 - Water Pump, Check Valves, Blow Down Valve, Pressure Gauge, Pipe Work

This kit turned out to be so far the most difficult one.

Blow Down Valve BU22152

That was pretty easy. The photo below shows how it looks after filing off the edges from the Washer BU2216

Water Lifter Pipes BU22163 & 64

These pipes are mentioned at the end of the instructions. But it is essential that they get assembled before installing the Water Pump. Otherwise it wouldn't be possible to fix the union nut to the globe valve at the lefthand side of the steamhead.

Recommendation to STW: Put this part of the instruction to the beginning.

Fastening the Double Pipe Union 001145 just in front of the Tender Tank was a problem. Standard wrenches are too long for this operation, the space for moving them is very limited. I had to cut two of them into parts.

In the photo you can see that i took some materia off from the end of the 3/8-inch wrench to get more space for movement.

karl heinz marschner- Number of posts : 33

Location : Duesseldorf, Germany

Registration date : 2021-04-13

Dickinson likes this post

Re: Putting together a Burrel in Duesseldorf

Re: Putting together a Burrel in Duesseldorf

Water Pump Assembly

A long time ago I had started to add the names of the various parts into the ISO- drawings. This makes it much easier for me to read and understand the instructions.

When I started to assemble the pump I encountered a problem: The Water Pump Ram Bush BU22135 did not fit into the Water Pump Ram BU22137. And there was this pretty long fastener M 4x15 csk skt. How deep should the Ram Bush go into the Ram? To make the long story short, it has to go right to the bottom of the Ram. The fastener has to get shortened. And I had to rework the bore in the Ram by using a reamer.

Recommendation to STW: Please put a hint for this into the instructions. At least for me it was not as obvious as it looked afterwards.

By the way: I replaced the fastener by one with TORX-drive. For final assembly I will seal it with Loctite.

Water Pump Suction Chamber with 6 mm SS-ball:

I found another problem where I had to take care for. The suction Chamber with the 6 mm SS-ball seemed to be not deep enough. It is that part of the Pump Body where the Water Pump CV Connector BU22126 goes into. So I made me another drawing and took some measurements.

Therefore I was right with my suspicion. I had to make the suction chamber including this trefoil-shaped recess deeper by 1 mm.

Fixing the Water Pump to Eccentric Strap and LH Hornplate

This procedure came out as so far the most difficult period during the build of my 2 inch Burrel. I had made a serious mistake. I had already fastened both parts of the Eccentric Strap BU21909 (see kit no. 19 - Valve Gear) to the camshaft. This was good for the Valve Gear, but it was a very bad idea for the pump. I will spare you the details. I finally made it, but it was a real nightmare.

Urgent recommendation to STW: Please put a hint into the instruction. Do not fix the Pump Eccentric Strap to the camshaft before installing the Water Pump.

And then I found out that the Water Pump Rod BU22138 collided with the Water Pump Ram BU22137. So I had to take everything apart again. This was a good moment for me to think it over. Could I eventually find a way to make this prozedure easier for me? I ended up with the design of some very small very special tools for me.

And I changed the lower two tapped holes for fixing the Water Pump to the LH Hornplate into through-holes with 3,5 mm diameter.

Now I started to put all parts of the Water Pump together including the Water Pump Gland BU22134 and a Gland Packing of approximately 4 turn of graphited yarn.

The Eccentric Strap does not go through the opening of the rear spectacle plate. So, when fixing the Water Pump Rod to the rear part of the Eccentric Strap you have to come from both sides of the Rear Spectacle Plate.

The two long cheese head fasteners for putting the two parts of the Eccentric Strap together, I had secured with instant adhesive beforehand. Now my new very small fastening tools turned out to be extremely practical.

For easier handling I had temporarely loosened the front spectacle plate and pushed forward as far as possible.

After fixing the Water Pump to the LH Hornplate with only one fastener, I started to fit the two Water Pipes BU22161 (WP Feed Pipe) and BU22160 (WP Bypass Pipe) in between Water Pump and Water Tank. You need some up & down movement of the Pump to get the two pipes in between. One of the pipes turned ot to be a little bit too long. I had to put an additional bend to it to overcome this problem. See photo below.

After fixing those pipes I was ready to fix the rest of the fasteners to fix the pump to the Horn Plate finally.

It was still a tricky procedure. There is not much room for your hands, not much room to move your fastening tools, and sometimes you cannot see what you are doing.

Two Check Valves BU22113 for both sides of the boiler

The seats for the SS-balls do not look very precisely. I gave the balls a slight hit with a small hammer, and can only hope that they will prove tight enough.

A long time ago I had started to add the names of the various parts into the ISO- drawings. This makes it much easier for me to read and understand the instructions.

When I started to assemble the pump I encountered a problem: The Water Pump Ram Bush BU22135 did not fit into the Water Pump Ram BU22137. And there was this pretty long fastener M 4x15 csk skt. How deep should the Ram Bush go into the Ram? To make the long story short, it has to go right to the bottom of the Ram. The fastener has to get shortened. And I had to rework the bore in the Ram by using a reamer.

Recommendation to STW: Please put a hint for this into the instructions. At least for me it was not as obvious as it looked afterwards.

By the way: I replaced the fastener by one with TORX-drive. For final assembly I will seal it with Loctite.

Water Pump Suction Chamber with 6 mm SS-ball:

I found another problem where I had to take care for. The suction Chamber with the 6 mm SS-ball seemed to be not deep enough. It is that part of the Pump Body where the Water Pump CV Connector BU22126 goes into. So I made me another drawing and took some measurements.

Therefore I was right with my suspicion. I had to make the suction chamber including this trefoil-shaped recess deeper by 1 mm.

Fixing the Water Pump to Eccentric Strap and LH Hornplate