Kit 11 - Cylinder Block & Cylinder fittings.

+2

lynnr

milford59

6 posters

Page 1 of 2

Page 1 of 2 • 1, 2

Kit 11 - Cylinder Block & Cylinder fittings.

Kit 11 - Cylinder Block & Cylinder fittings.

This is where it starts to get more interesting and tricky.... now we seems to be at the stage where accuracy of the parts is absolutely crucial. The very first thing to do is to slide the glands onto the piston rod and presumably they seat down into the cover in the direction shown in my picture..... problem is the gland has an o/d of 20.17mm and the hole has an inside diameter of 19.70mm.

Am I doing something wrong, or is the part too big.

Thanks for any advice.

Am I doing something wrong, or is the part too big.

Thanks for any advice.

milford59- Number of posts : 307

Location : Milford on Sea

Registration date : 2019-05-19

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Re: Kit 11 - Cylinder Block & Cylinder fittings.

I would say you hit the wrong end of tolerances. Have a word with Will and all will be sorted quickly.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Thank you very much Lynn - I have sent an email to Will.

milford59- Number of posts : 307

Location : Milford on Sea

Registration date : 2019-05-19

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Re: Kit 11 - Cylinder Block & Cylinder fittings.

I contacted Will, and he has very kindly offered to find 2 new brass glands to suit the size of the cover. That. is top service. Thanks Will !!

Edited, to say it turns out that the covers have been made with the holes a bit too small, according to Will, so I have sent mine back and it will be adjusted along with the others that STW have in stock.

Edited, to say it turns out that the covers have been made with the holes a bit too small, according to Will, so I have sent mine back and it will be adjusted along with the others that STW have in stock.

milford59- Number of posts : 307

Location : Milford on Sea

Registration date : 2019-05-19

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Re: Kit 11 - Cylinder Block & Cylinder fittings.

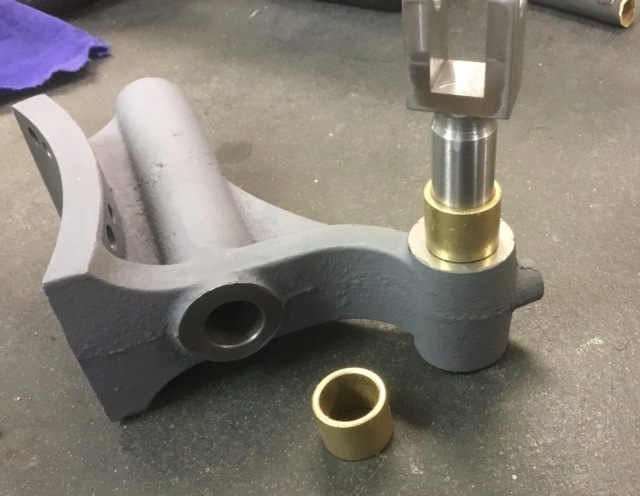

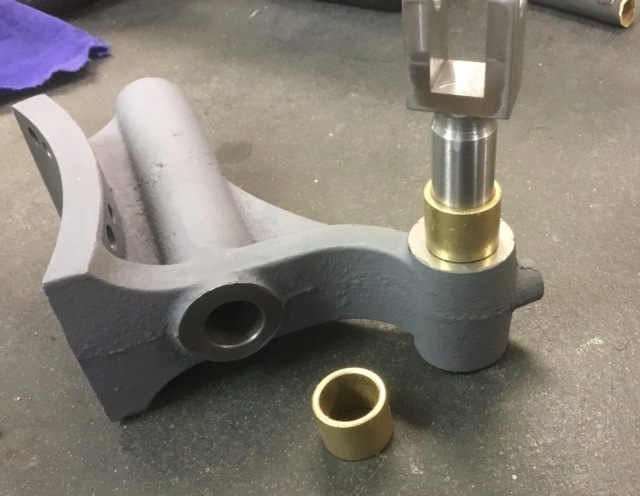

Ok - let’s move on to the next problem. The valve rod guide hole and the valve rod are the same dimensions, so the valve rod is a nice sliding fit into the guide hole...... BUT there are 2 bushes that are supposed to go in there first.... the bushes are a sliding fit onto the valve rod, so my only conclusion is that the valve rod guide hole is drastically undersized. I am going to send a message to Will.

Valve rod is a sliding fit...

Bushes won’t go in....

Valve rod is a sliding fit...

Bushes won’t go in....

milford59- Number of posts : 307

Location : Milford on Sea

Registration date : 2019-05-19

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Re: Kit 11 - Cylinder Block & Cylinder fittings.

The weighshaft bracket is going back to Will to be drilled out to 20mm so that the bushes will fit.

milford59- Number of posts : 307

Location : Milford on Sea

Registration date : 2019-05-19

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Re: Kit 11 - Cylinder Block & Cylinder fittings.

I have got the weighshaft bracket and the cover and glands back from Will (thanks very much Will !!). , so I am all set to start dry assembling parts onto the Cylinder block, which is arriving on Monday !

milford59- Number of posts : 307

Location : Milford on Sea

Registration date : 2019-05-19

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Re: Kit 11 - Cylinder Block & Cylinder fittings.

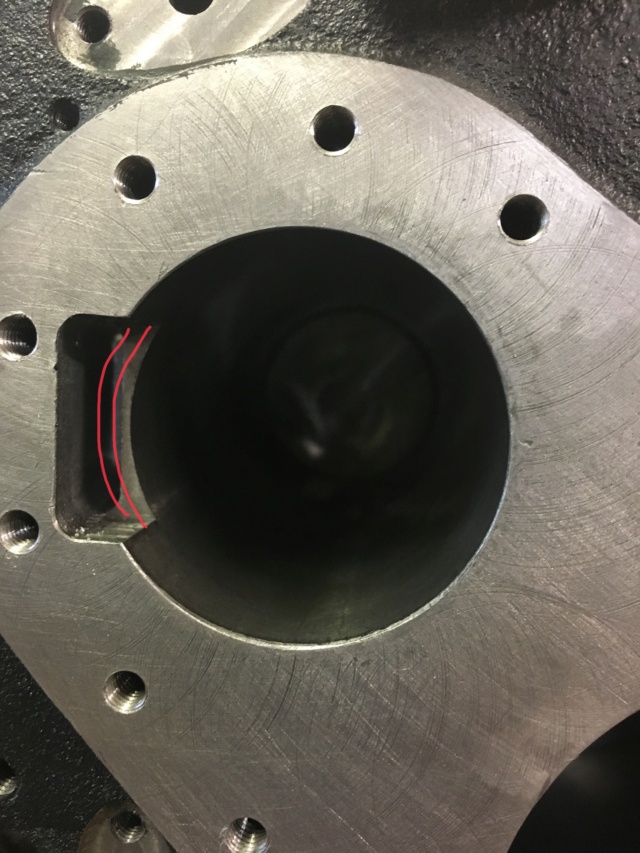

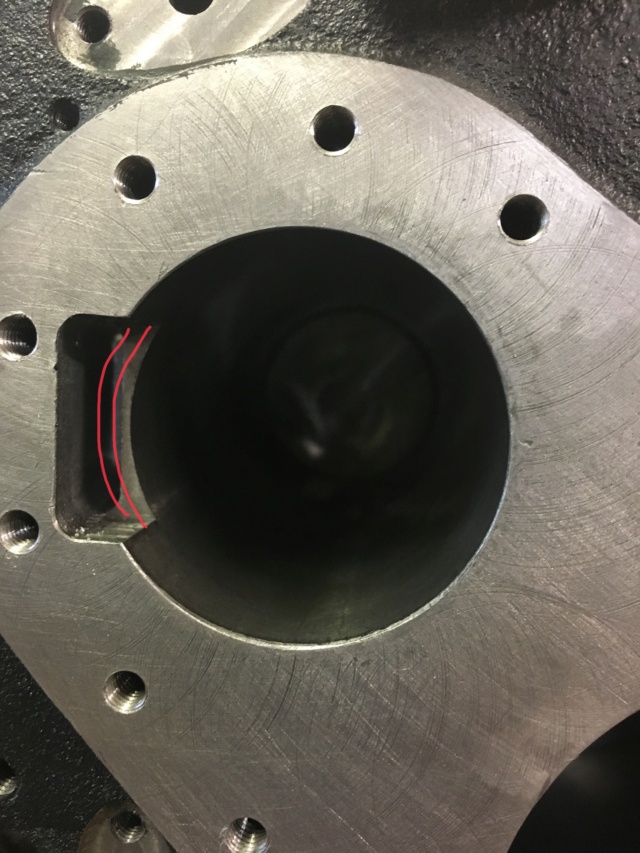

I am starting to dry-assemble the cylinder block and fittings...Can anyone please give me a tip on getting the small piston into the bore..... I can compress the rings ok with my hands and get it in part way but then the front ring springs out a bit and will not go past the part shown on the picture.... I tried gentle leverage with a screwdriver, but that didn’t work... Thanks for any advice.

EDITED:- Just after I hit “send”, I thought , why not put it in from the other side !!.... That must be the way to do it !!

(can you tell that I’ve never built one of these before !!)

EDITED:- Just after I hit “send”, I thought , why not put it in from the other side !!.... That must be the way to do it !!

(can you tell that I’ve never built one of these before !!)

milford59- Number of posts : 307

Location : Milford on Sea

Registration date : 2019-05-19

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Making some progress on the cylinder fittings..... it took me quite a while to get the rod and the glands all lined up and the packing inserted in the glands.... the rod is a bit stiff, but I guess it needs to be steam tight... the regulator valve is very smooth on the plate, after I lapped it in... as per the instructions..

milford59- Number of posts : 307

Location : Milford on Sea

Registration date : 2019-05-19

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Make sure the gap in the rings is always well away from the ports and the drain valve holes

Mark the spark- Number of posts : 389

Location : Edinburgh

Registration date : 2015-04-26

milford59 likes this post

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Re: Kit 11 - Cylinder Block & Cylinder fittings.

You need to check the ring has a big enough gap so when compressed in to the bore it has 2 or 3mm gap (if I remember my expansion right).

When inserting always put the gap furthest away from any bore opening.

On my engine the rings went in with gentle pressure on the piston and run a screwdriver round the surface of the ring to "compress" it in to the piston. You can also put a slight taper on the steam port edge to aide the piston ring sliding past the port. Once connected up it does not reach the ports.

When inserting always put the gap furthest away from any bore opening.

On my engine the rings went in with gentle pressure on the piston and run a screwdriver round the surface of the ring to "compress" it in to the piston. You can also put a slight taper on the steam port edge to aide the piston ring sliding past the port. Once connected up it does not reach the ports.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Re: Kit 11 - Cylinder Block & Cylinder fittings.

lynnr wrote:You need to check the ring has a big enough gap so when compressed in to the bore it has 2 or 3mm gap (if I remember my expansion right).

When inserting always put the gap furthest away from any bore opening.

On my engine the rings went in with gentle pressure on the piston and run a screwdriver round the surface of the ring to "compress" it in to the piston. You can also put a slight taper on the steam port edge to aide the piston ring sliding past the port. Once connected up it does not reach the ports.

Thank you very much Lynn

EDITED....All sorted.... your crucial advice (which wouldn’t go amiss in the instructions) is to put the ring inside the bore on its own and see how much gap there is (in my case virtually zero).... then file the ring ends a little to get the 2mm gap, when it’s in the bore on its own.....then when the rings are back on the piston it goes in easily.

Last edited by milford59 on Sun 09 May 2021, 9:13 am; edited 2 times in total

milford59- Number of posts : 307

Location : Milford on Sea

Registration date : 2019-05-19

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Thanks very much Mark..Mark the spark wrote:Make sure the gap in the rings is always well away from the ports and the drain valve holes

milford59- Number of posts : 307

Location : Milford on Sea

Registration date : 2019-05-19

Mark the spark likes this post

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Re: Kit 11 - Cylinder Block & Cylinder fittings.

I am going to be attaching the cylinder to the boiler fairly soon, but I am a bit confused by this part of the instructions:-

I don’t think I have the Cylinder Drain Boss yet - I certainly haven’t fitted it ! Are these instructions old ? I see that there has been a bit machined out of the cylinder on the chimney side ... maybe this used to be an issue, but isn’t any more ? Any info would be much appreciated>

I don’t think I have the Cylinder Drain Boss yet - I certainly haven’t fitted it ! Are these instructions old ? I see that there has been a bit machined out of the cylinder on the chimney side ... maybe this used to be an issue, but isn’t any more ? Any info would be much appreciated>

milford59- Number of posts : 307

Location : Milford on Sea

Registration date : 2019-05-19

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Re: Kit 11 - Cylinder Block & Cylinder fittings.

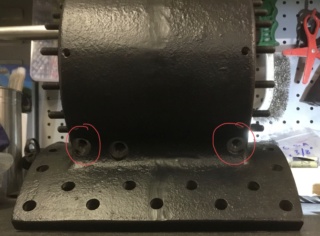

The drain Bosses are the cast in threaded holes below the LP cylinder. You can see the hole on the inside of the bore. These two are the drains. Depending on tolerances you might have to feed the two studs in to the holes on the block from under the saddle before placing the block on to the boiler. Hold them in place with some tape.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

milford59- Number of posts : 307

Location : Milford on Sea

Registration date : 2019-05-19

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Yes

Looks like a different design from when the instructions were written. There should be no issue now.

Looks like a different design from when the instructions were written. There should be no issue now.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Re: Kit 11 - Cylinder Block & Cylinder fittings.

lynnr wrote:Yes

Looks like a different design from when the instructions were written. There should be no issue now.

OK good news - thanks again - I really appreciate your quick, and always helpful, replies.

milford59- Number of posts : 307

Location : Milford on Sea

Registration date : 2019-05-19

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Hi Milford

Just looked at the SCC block and all the studs will fit from the top. However there is a BUT.

No3 and No4 shown on the instruction above might be a problem if you have the screws in the front and rear covers.

If you haven't used Locktight on them then you will be able to remove them until the M8 studs are in place.

If you have used the Locktight then these are the 2 that you will need to fit in the way Lynn described above.

hope that helps.

Simon C

Just looked at the SCC block and all the studs will fit from the top. However there is a BUT.

No3 and No4 shown on the instruction above might be a problem if you have the screws in the front and rear covers.

If you haven't used Locktight on them then you will be able to remove them until the M8 studs are in place.

If you have used the Locktight then these are the 2 that you will need to fit in the way Lynn described above.

hope that helps.

Simon C

Simon C- Number of posts : 304

Location : Derby

Registration date : 2017-07-07

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Simon C wrote:Hi Milford

Just looked at the SCC block and all the studs will fit from the top. However there is a BUT.

No3 and No4 shown on the instruction above might be a problem if you have the screws in the front and rear covers.

If you haven't used Locktight on them then you will be able to remove them until the M8 studs are in place.

If you have used the Locktight then these are the 2 that you will need to fit in the way Lynn described above.

hope that helps.

Simon C

Thank you very much Simon - more excellent information ... after my cock-up with the perch bracket, I am being very cautious about the timing of any thread lock !! I haven’t yet done that for the cover screws, so that’s good news. I appreciate your help.

milford59- Number of posts : 307

Location : Milford on Sea

Registration date : 2019-05-19

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Re: Kit 11 - Cylinder Block & Cylinder fittings.

After a lot of work, I am ready to mount the cylinder on to the boiler. The instructions make it sound like you just slap some Foliac on and bolt it down. Of course this is a million miles from reality. If you don’t make sure that every stud will go in at least a couple of turns by hand before you attempt to fit the cylinder, you may find yourself in a world of pain. So that means painstakingly filing every hole so that the studs go in easily. If not you will get half way through and find a stud won’t go in and then you are knackered. Foliac all over the place......can’t get the studs out easily etc. etc. There is no way that the holes in the boiler and the holes in the cylinder could be drilled to align without fettling.... that’s no issue but perhaps the instructions should make that clear ?New builders take note.

milford59- Number of posts : 307

Location : Milford on Sea

Registration date : 2019-05-19

LiveSteam and Mutleybob like this post

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Re: Kit 11 - Cylinder Block & Cylinder fittings.

I have now got the cylinder fitted, although I stripped the thread on one stud - I am not quite sure what I did wrong, but clearly “user error”....anyway, I have ordered a few replacements - luckily they are a bog-standard stud that is used on many car exhaust manifolds - I will sort that in a few days time, when the new stud arrives.

This is how it is looking now, and I am going to give the cylinder a paint touch-up before I put any parts back on.... I am also painting the sides of the boiler with their final coat so that I will be ready to attach the hornplates.

This is how it is looking now, and I am going to give the cylinder a paint touch-up before I put any parts back on.... I am also painting the sides of the boiler with their final coat so that I will be ready to attach the hornplates.

milford59- Number of posts : 307

Location : Milford on Sea

Registration date : 2019-05-19

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Hi Milford59

Before you grab your paint brush you will need to trim a few of the studs holding the block on.

As it is in your picture you will struggle getting the front and rear covers on.

At the front of the block there is a stud in a recess under the blast pipe that will need cutting or it will prevent the blast pipe fitting to the block.

Simon C

Before you grab your paint brush you will need to trim a few of the studs holding the block on.

As it is in your picture you will struggle getting the front and rear covers on.

At the front of the block there is a stud in a recess under the blast pipe that will need cutting or it will prevent the blast pipe fitting to the block.

Simon C

Simon C- Number of posts : 304

Location : Derby

Registration date : 2017-07-07

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Simon C wrote:Hi Milford59

Before you grab your paint brush you will need to trim a few of the studs holding the block on.

As it is in your picture you will struggle getting the front and rear covers on.

At the front of the block there is a stud in a recess under the blast pipe that will need cutting or it will prevent the blast pipe fitting to the block.

Simon C

Thanks very much for that tip Simon - I guess it would look a bit wrong to cut down just the ones that foul the covers and the blast pipe....Hopefully the studs will never need to come out again, and if they did, they could be removed with mole-wrench or similar , and new ones fitted.... I haven’t loctited them in - I used PTFE tape..although I guess I could cut them down to an extra one-nut height and that would enable them to be removed, with two nuts - I have looked at pictures and it seems that is what others have done...?

milford59- Number of posts : 307

Location : Milford on Sea

Registration date : 2019-05-19

Re: Kit 11 - Cylinder Block & Cylinder fittings.

Re: Kit 11 - Cylinder Block & Cylinder fittings.

I am now fitting the valves into this chamber and the lower one is a bit stiff towards the end of its travel, but it occurs to me that maybe it doesn’t actually move that far backwards and forwards, so perhaps I don’t need to get it smooth the whole way back and forwards. Could someone kindly tell me how much actual movement there is when the engine is running - Thanks very much.

milford59- Number of posts : 307

Location : Milford on Sea

Registration date : 2019-05-19

Page 1 of 2 • 1, 2

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum|

|

|