gears again

4 posters

Page 1 of 2

Page 1 of 2 • 1, 2

gears again

gears again

I installed the new gears as per the assy instructions. Yesterday I moved the car about 20 feet and it stopped and would not move. I pushed it into the shop and dropped the diff. To my suprise the pinion gears teeth were broken off on all pinions again. The axle gears were ok. I'm at a loss as to why this is happening. What I need if any one knows the pressure angle of the gears is it 14.5 or 20 degs.

Dean do you have any thoughts on this problem.

Dean do you have any thoughts on this problem.

jjtjr- Number of posts : 229

Age : 76

Location : New Jersey,usa

Registration date : 2009-07-28

Re: gears again

Re: gears again

When you tighten the wheel castle nut were you able to bind the bearings up a bit where the wheel was stiff to turn? Once that occurs you need to back off just enough to where the wheel spins freely. This would mean that the two taper bearings are set with minimal to no freedom to allow the axle to move. Also I would suggest that the pinion gear teeth can be faced off even more further away from the axle gear. There is plenty of gear face to drive everything and a little less won’t matter in the grand scheme of things.

I’m so sorry to hear this has happened again. But something is allowing the movement of the axle for this to have happened again.

I’m so sorry to hear this has happened again. But something is allowing the movement of the axle for this to have happened again.

Grier- Number of posts : 67

Location : Topsail Beach, NC

Registration date : 2015-05-15

Re: gears again

Re: gears again

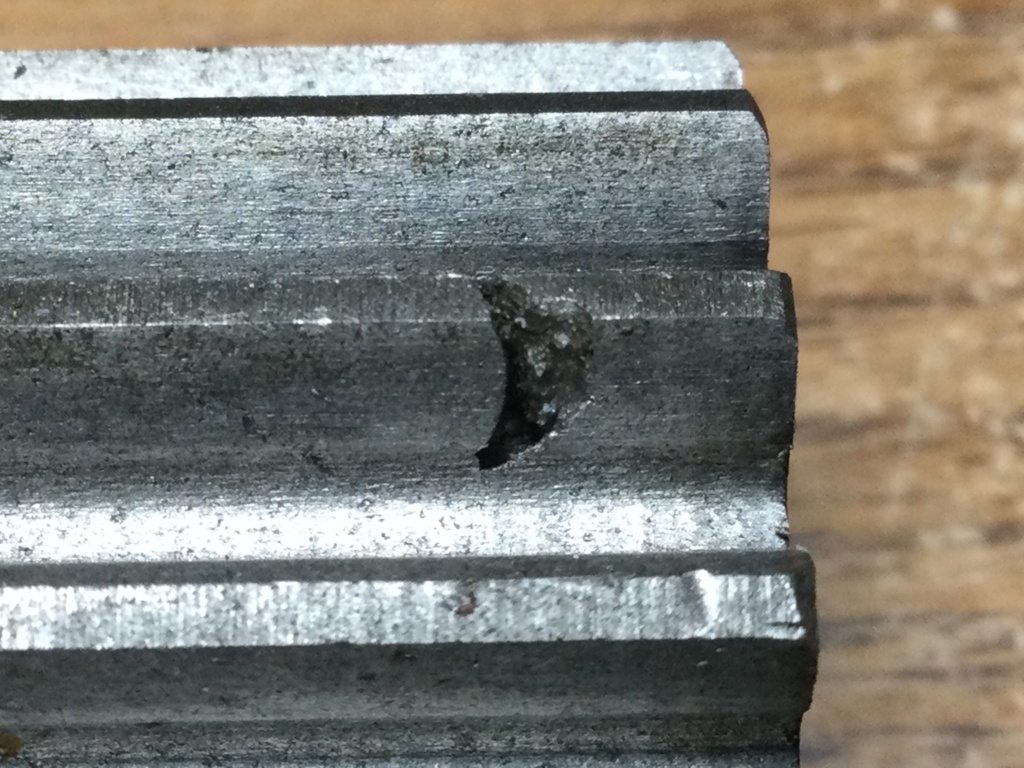

So as I understand this differential, the outer case is driven by the chain and sprocket from the engine and the torque of that is transferred to the axle gear by way of the smaller pinions in the differential. The pinions are actually stationary if you are driving a straight line and only rotate when taking a turn etc. so all of the power goes through these pinions to the wheel axle gears. The failure I see is that the pinion gears failed in transferring that torque to the wheel axles while turning or cornering. The pinions were stripped in the inner portion where this torque or power from the chain and sprocket is transmitted. You stated the larger wheel axle gears were okay and looking at your photo that is also showing by way of the outboard sections of the pinion gears being relatively still intact.

So this is a different failure from your first failure I believe. The pinion gears failed possibly because your surrey is heavier? That’s possible, or there is something else binding in the axle torque tubes? Out of curiosity did you try spinning the axles? Did it feel normal? Another possibility is that one side or wheel was dragging putting pressure on the inner pinion gear portion and the teeth snapped.

Finally if it were me I would make the pinion gears out of 1040 cold rolled steel. Previously you asked about pressure angle and the most typical nowadays is 20 degrees. 14.5 was an older standard that is still in use but not as frequent now.

So this is a different failure from your first failure I believe. The pinion gears failed possibly because your surrey is heavier? That’s possible, or there is something else binding in the axle torque tubes? Out of curiosity did you try spinning the axles? Did it feel normal? Another possibility is that one side or wheel was dragging putting pressure on the inner pinion gear portion and the teeth snapped.

Finally if it were me I would make the pinion gears out of 1040 cold rolled steel. Previously you asked about pressure angle and the most typical nowadays is 20 degrees. 14.5 was an older standard that is still in use but not as frequent now.

Grier- Number of posts : 67

Location : Topsail Beach, NC

Registration date : 2015-05-15

gears

gears

Grier, Since I have the diff. out of the car I will jack up both wheels and spin the axles and check to see if there is any binding. Before I make any gears I am checking with STW, I don't want to assume the pressure angle is 20 degs. The plan would to make the pinion gears from 4140 steel which can be case hardened, I already purchased the bar stock, and cut them and have the gear case hardened, somewhere around .010" to .020" deep, its best not to hardened the whole gear only the teeth because it will become to brittle. Dean and I have a phone call set up on monday to discuss the problem. Its interesting how the original gears lasted around 10 years and now the new gears worked for 20 feet. Once I confirm the pressure angle is 20 degs I will order the cutters and try to make them this Dec. since I will be flying back to New Jersey for the holidays and be there for about 4 weeks.

After degreasing the diff. I placed half of it on the axles and looked to see if the axle gears was trying to strike the other pinion gear, from what I was able to see there was clearance so that wasn't the problem that caused them to break. This would mean if my thinking is correct the cast gears can't handle the torque. I'm wondering why the gears were cast in the first place, I would thing any gear that transmits torque would be heat treated. When I did an HRC test on the pinion gears I think it was below 40. I was using the HRC file kit which includes 5 test files from 65 HRC to 40 HRC. When testing it was below 40. All the specs. that I read on pinion gears the HRC number should be between 50 to 60. If there is no binding this could be the problem and making the new gears would fix the problem. In the meantime Dean is sending me another set of pinions gears. The car is with me here in florida since I go to quite a few car shows in the area. I would like to get it fixed asap its still early in the season.

After degreasing the diff. I placed half of it on the axles and looked to see if the axle gears was trying to strike the other pinion gear, from what I was able to see there was clearance so that wasn't the problem that caused them to break. This would mean if my thinking is correct the cast gears can't handle the torque. I'm wondering why the gears were cast in the first place, I would thing any gear that transmits torque would be heat treated. When I did an HRC test on the pinion gears I think it was below 40. I was using the HRC file kit which includes 5 test files from 65 HRC to 40 HRC. When testing it was below 40. All the specs. that I read on pinion gears the HRC number should be between 50 to 60. If there is no binding this could be the problem and making the new gears would fix the problem. In the meantime Dean is sending me another set of pinions gears. The car is with me here in florida since I go to quite a few car shows in the area. I would like to get it fixed asap its still early in the season.

jjtjr- Number of posts : 229

Age : 76

Location : New Jersey,usa

Registration date : 2009-07-28

gears

gears

When the car was first built as a two seater its weight about 900 pounds dry, when it got extended it now weighs 1500 pounds dry. Could this contributing to the problem ?

jjtjr- Number of posts : 229

Age : 76

Location : New Jersey,usa

Registration date : 2009-07-28

Re: gears again

Re: gears again

4140 is a good choice. I have used this steel also for spur gears. Also thinking some more on the failure, going only 20 feet really points to something binding up quickly. I know on my differential I had to enlarge the holes a bit on my pinion bolts to make sure that my gears did not bind up. Meaning I had to move the pinion gears apart some to get some backlash - not much, but enough so that the gears were able to rotate fairly freely and not bind.

Grier- Number of posts : 67

Location : Topsail Beach, NC

Registration date : 2015-05-15

gears

gears

That's a good point, when I get the new gears I will make sure that they turn freely. Since I will be flying back to NJ did you want me to assy a control board for you? If so let me know. You will have to fabricate a box for it to fit into. I could take some photos with measurements, Its easy to bend one up using brass sheet. A brake works best you get nice bends.

jjtjr- Number of posts : 229

Age : 76

Location : New Jersey,usa

Registration date : 2009-07-28

gears

gears

Here is the latest on the gears, Ian from STW called me on my cell phone USA from England, The call was very productive there plan is to make new pinion gears from steel not cast iron and mail them to me, I then can if I desire to have them case hardened. I asked if they could be made from 4140 steel or there equivalent, he said that was possible. The lead time was about 2 weeks. STW is doing a great job with this problem. Thanks again to the team at STW. My next trip to England after the virus is over I will visiting the team at STW.

Jim Trotta

Jim Trotta

jjtjr- Number of posts : 229

Age : 76

Location : New Jersey,usa

Registration date : 2009-07-28

LiveSteam likes this post

Gears again

Gears again

Got the new gears from STW. Did a close inspection before installing them and this is what I found.

jjtjr- Number of posts : 229

Age : 76

Location : New Jersey,usa

Registration date : 2009-07-28

jjtjr- Number of posts : 229

Age : 76

Location : New Jersey,usa

Registration date : 2009-07-28

neuedinger likes this post

Cutting gears

Cutting gears

Gear cutting one tooth at a time

jjtjr- Number of posts : 229

Age : 76

Location : New Jersey,usa

Registration date : 2009-07-28

Gears

Gears

Yep the gears that i posted are cast. These are the ones STW sent me to replace the ones that i purchased and only work for 20'. I chucked them up on the lathe and turn them and yes they are cast. Dean said they will making the new ones from steel alloy but this will not happen until after the first of the new year. In the mean time i am making new ones from 4140. Them have them case hardened. This will allow me to use the car.

jjtjr- Number of posts : 229

Age : 76

Location : New Jersey,usa

Registration date : 2009-07-28

Gears

Gears

Just finished machining first of 4 gears 3 more to go made from 4140 stock once all 4 are done will get case hardened.Cutting goes slow i'm not using a CNC mill but and old j head Bridgeport with DRO and motorized x axis. I set the stops and then have to move the y axis and so another cut. The feed rate for the x axis is slow because don't want to dull the cutter. Only removing .030"per pass until .212 tooth depth. Then move to next tooth. It takes about a day to complete one gear. Slow and steady does it can't make any mistakes.

jjtjr- Number of posts : 229

Age : 76

Location : New Jersey,usa

Registration date : 2009-07-28

Re: gears again

Re: gears again

I love McMaster Carr. Great resource. I still have one of their massive catalogs from my pre-retirement career. I wonder if they still make them.

Grier- Number of posts : 67

Location : Topsail Beach, NC

Registration date : 2015-05-15

Re: gears again

Re: gears again

Hi

Yes they still have a paper Catalogue. Adam Savage from Mythbusters talking about it.

Yes they still have a paper Catalogue. Adam Savage from Mythbusters talking about it.

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

Gears

Gears

I live less then 1 hr drive from them, when i can't wait for it to be shipped i do a will call and pick it up that same day great place and have a catalogue also but on line is faster.

jjtjr- Number of posts : 229

Age : 76

Location : New Jersey,usa

Registration date : 2009-07-28

Too many gears

Too many gears

Well I'm at it again. Just received bar stock of 8620 alloy. Since all my machines are setup for gear cutting. I'm making another set of pinion gears. This time I will be machining it a little different, instead of 4 blanks, I will be using 2 blanks but twice the lengths. Then after cutting the teeth I will be parting it, then facing them. My hope is this will be faster. Then off to be heat treated case hardened to about .030" , looking to have it between 50 to 60 HRC

jjtjr- Number of posts : 229

Age : 76

Location : New Jersey,usa

Registration date : 2009-07-28

Gear cutting

Gear cutting

Cutting gears again i just can't stop. Using different alloy and double the length, they will be parted at the end. Then be case hardened. While the gear cutting is happening starting to build a heat treating oven, drew up the plans 12" by 12" 18" long. Just picked the fire brick up this morning. Ordered the nichrome wire for winding the heating elements. It will be using 220 vac. Purchased a PID heat controller. The oven will have a temp. Range up to 2800 f* and be capable for heat treating and also for melting metal. I will be posting photos of the build.

https://youtu.be/cQfWTrCjJyo

https://youtu.be/VQbAGkdlCKk

https://youtu.be/CBd4nWdsRKY

https://youtu.be/cQfWTrCjJyo

https://youtu.be/VQbAGkdlCKk

https://youtu.be/CBd4nWdsRKY

jjtjr- Number of posts : 229

Age : 76

Location : New Jersey,usa

Registration date : 2009-07-28

Gears

Gears

Hi gents

I have just purchased an old mk1 and am trying to get my head around a number of issues it seems to have, I was intending to strip down the dif as I think it may have some broken Teath, can you advise me where I can get some drawings for the car.

Kevin

I have just purchased an old mk1 and am trying to get my head around a number of issues it seems to have, I was intending to strip down the dif as I think it may have some broken Teath, can you advise me where I can get some drawings for the car.

Kevin

Stokes- Number of posts : 3

Location : Derbyshire

Registration date : 2022-07-29

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Andy's 4"dcc road loco

» Bad sound coming from rear end

» Fun & Games with gears

» Bill's 6" Foden SWB Lorry

» Differential gears

» Bad sound coming from rear end

» Fun & Games with gears

» Bill's 6" Foden SWB Lorry

» Differential gears

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum|

|

|