september production photos...

+6

Capricorn1

Kevster

LiveSteam

hartshaulage

Road loco

craig@STW

10 posters

Page 1 of 1

september production photos...

september production photos...

ok, here are the long awaited photos of this months production.

just to clarify guys, i personally no longer have anything to do with production schedules and kit dispatch dates. we simply make what we are told when we are told.

all i can do now is post up pics of whats being worked on and because we don't always make parts in the same order they go out the door it can be a bit confusing. a lot of the things we make are just to top up stock

first parts are from the 6inch steering kit, steering shaft...

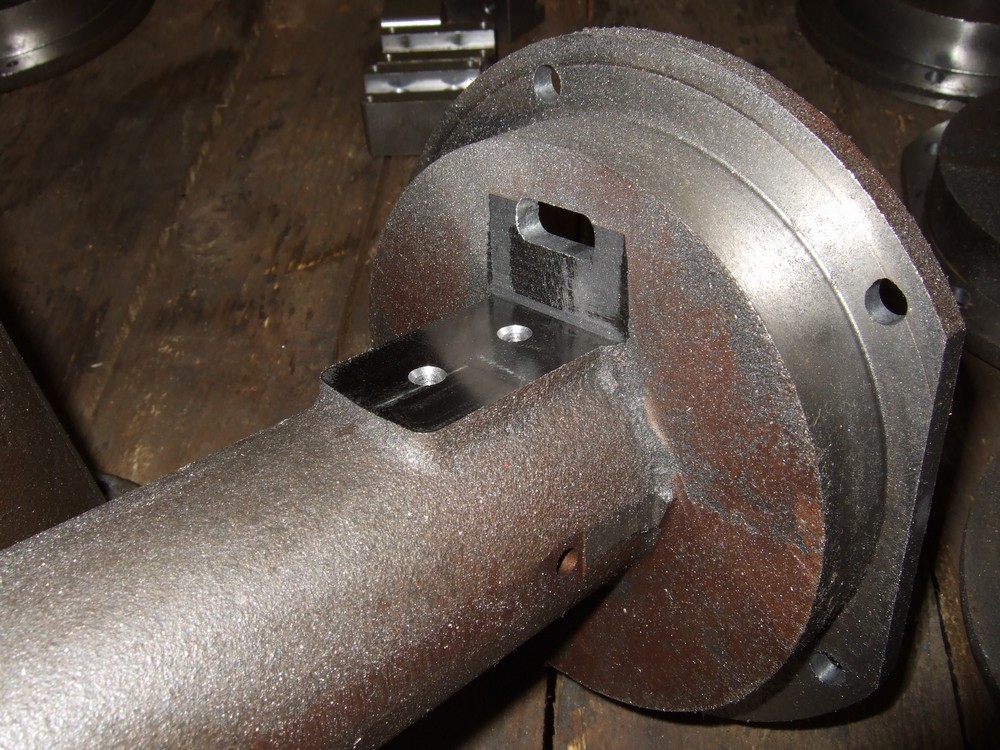

steering box...

steering wheels...

and steering con-rods...

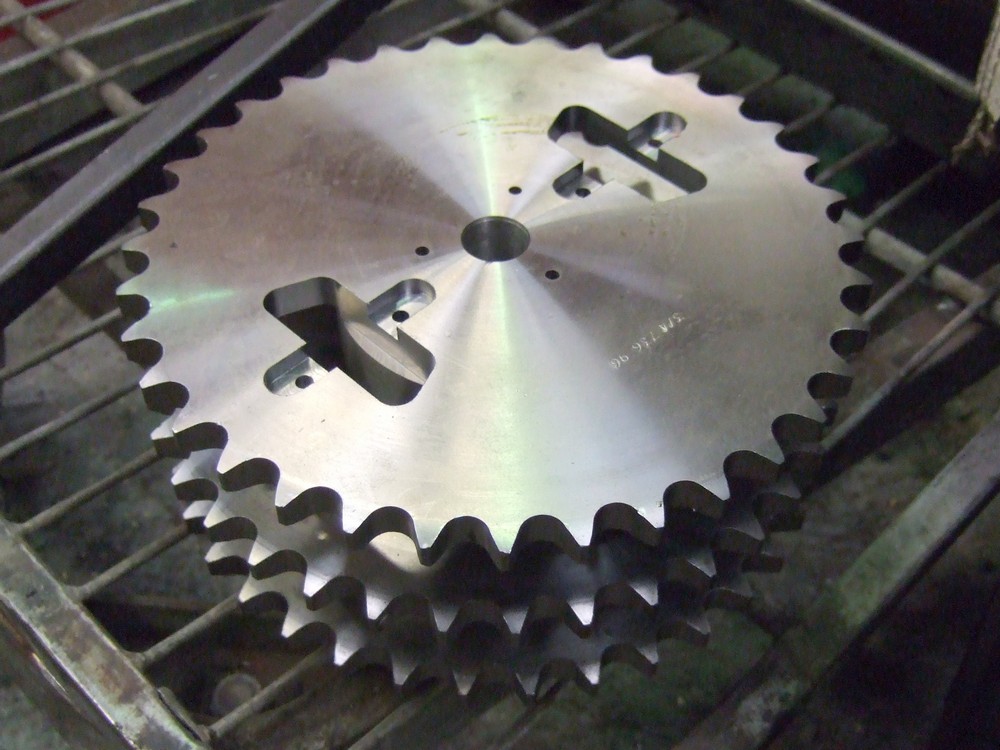

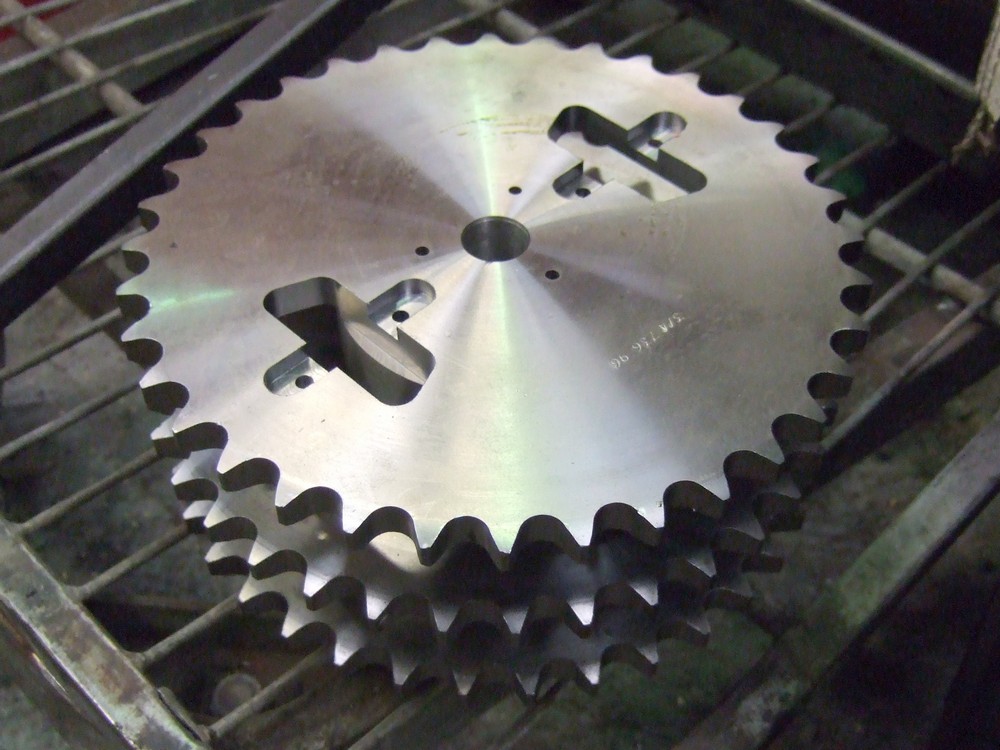

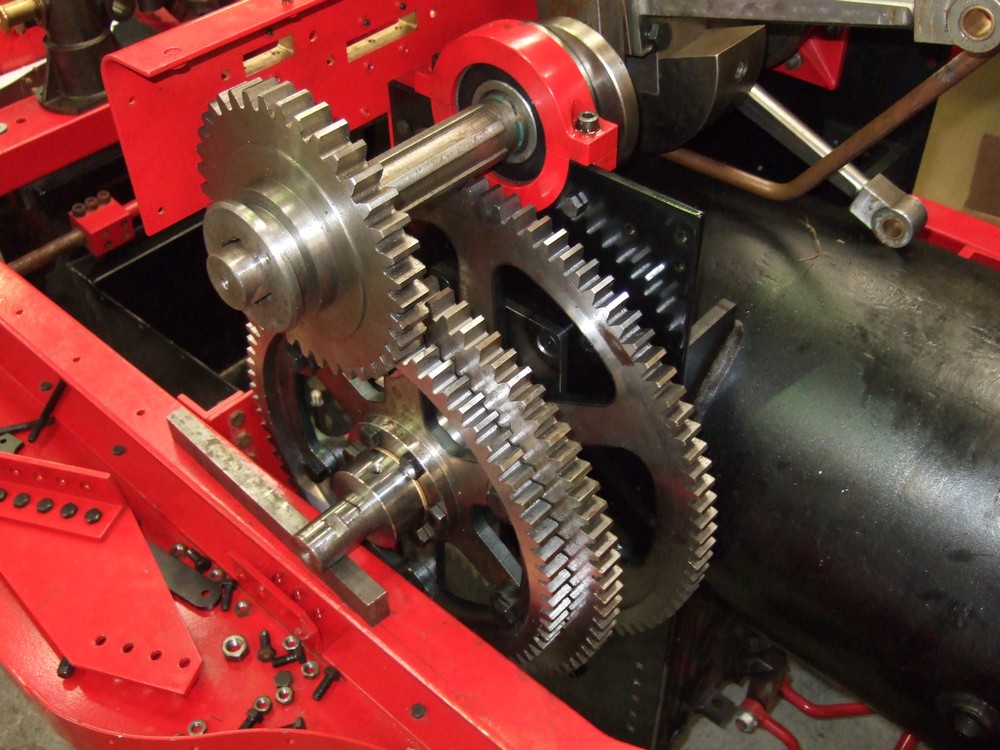

these are the main foden drive gears (for the 4inch i think ??)

heating and forming road-loco roof supports...

and we are always working on something for the boilers, this time its barrels...

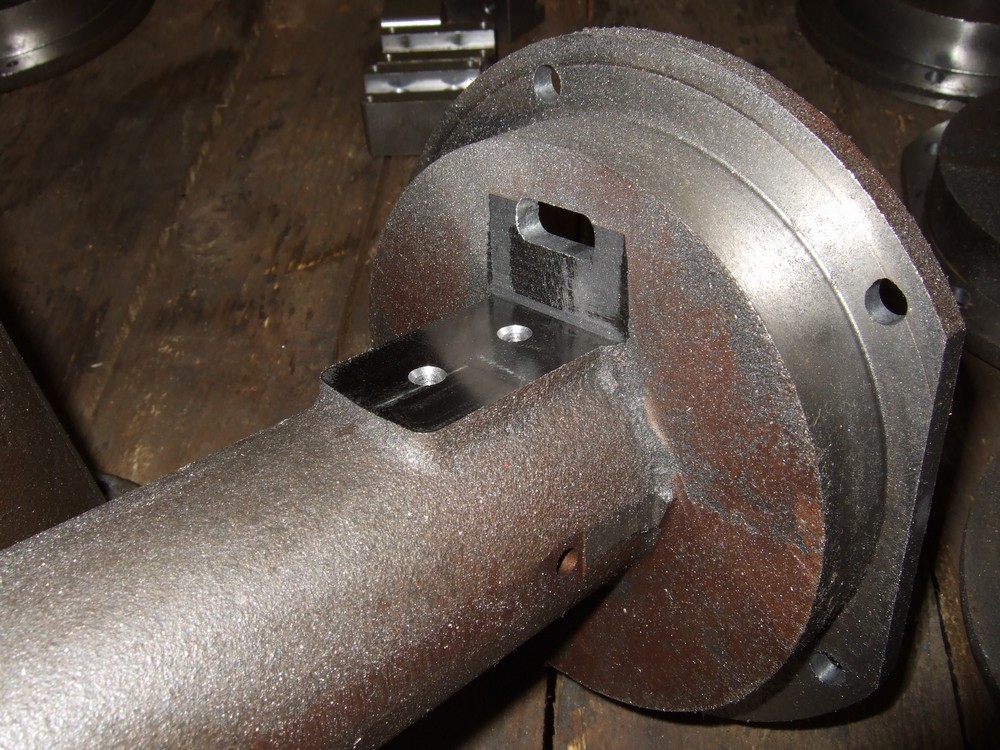

2nd shaft castings...

traction trailer parts...

4inch foden trunk guides...

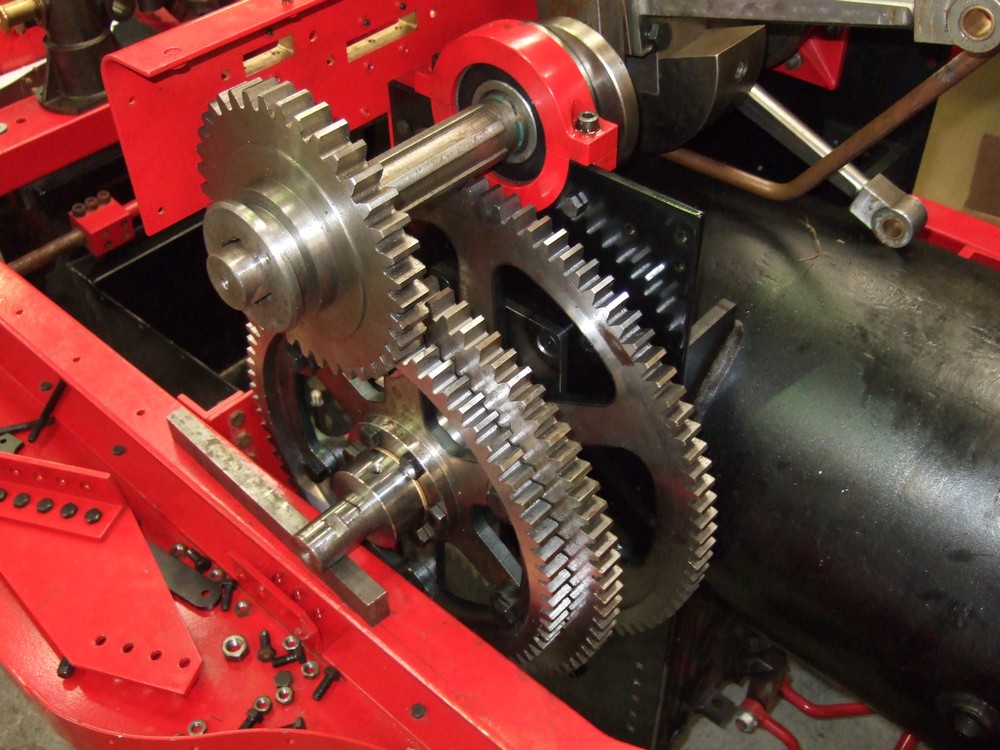

the 6inch foden gears going on the control model...

the latest batch of showmans/road-loco cylinders are nearly done...

showmans/road-loco brake shaft parts...

and 2inch horn-plates...

just to clarify guys, i personally no longer have anything to do with production schedules and kit dispatch dates. we simply make what we are told when we are told.

all i can do now is post up pics of whats being worked on and because we don't always make parts in the same order they go out the door it can be a bit confusing. a lot of the things we make are just to top up stock

first parts are from the 6inch steering kit, steering shaft...

steering box...

steering wheels...

and steering con-rods...

these are the main foden drive gears (for the 4inch i think ??)

heating and forming road-loco roof supports...

and we are always working on something for the boilers, this time its barrels...

2nd shaft castings...

traction trailer parts...

4inch foden trunk guides...

the 6inch foden gears going on the control model...

the latest batch of showmans/road-loco cylinders are nearly done...

showmans/road-loco brake shaft parts...

and 2inch horn-plates...

craig@STW- Number of posts : 1410

Location : location Location

Registration date : 2010-05-06

Re: september production photos...

Re: september production photos...

Yeh hey thank u for the pics hopefully here from Isabel soon, glad to see u all working hard

Road loco- Number of posts : 133

Location : Somerset

Registration date : 2014-08-04

Re: september production photos...

Re: september production photos...

Thanks for the update, i personally dont mind not knowing what ill be gettign next, its nice to know a rough date of arrival though, Keep up the good work

hartshaulage- Number of posts : 231

Age : 35

Location : Ilkeston, Derbyshire

Registration date : 2014-01-22

Re: september production photos...

Re: september production photos...

The quality of whats being made really looks amazing, makes me want to put a kit together, one day, maybe ones day.

LiveSteam- Number of posts : 788

Location : Hampshire

Registration date : 2013-09-08

Re: september production photos...

Re: september production photos...

Thanks for the update Craig,

Its always good to see whats going on in the factory.

Kev

Its always good to see whats going on in the factory.

Kev

Kevster- Number of posts : 424

Location : Hertfordshire 4 inch; DCC road loco

Registration date : 2011-01-27

Re: september production photos...

Re: september production photos...

I guess if you're not in "the trade" - engineering, then the photo's are very interesting.

However for me, August and now September have come and gone without having received a kit, that is now 4 months this year to date.

I'd rather see info regarding whether or not we're getting a kit, which one and when.

However for me, August and now September have come and gone without having received a kit, that is now 4 months this year to date.

I'd rather see info regarding whether or not we're getting a kit, which one and when.

Capricorn1- Number of posts : 119

Location : West Yorkshire.

Registration date : 2013-07-22

Re: september production photos...

Re: september production photos...

I completely concur with the above, whilst a kit a month is not guaranteed, I think we have slipped App. 33% in the first year. All we want is regular updates. Come on guys!

Dean did tease me at GDSF, saying the boilers may be out soon(er). I do hope so, as I will then start painting................maybe!

Mark.

Dean did tease me at GDSF, saying the boilers may be out soon(er). I do hope so, as I will then start painting................maybe!

Mark.

the governer- Number of posts : 69

Age : 68

Location : dorset

Registration date : 2013-10-06

Re: september production photos...

Re: september production photos...

Both Dean and I understand the motivation behind asking for some production schedules but we are both very reluctant to do so.

It’s not that we’ve got anything to hide, we’re just concerned that it would add a lot of confusion and potentially raise expectations that are not delivered. I’ll try to explain why further down this post.

By far the most important thing for us, is to be concentrating on us getting back on schedule with all our monthly deliveries, regardless of the model. There’s quite a few things that we’ve put in place to help this but it’s still going to be sometime before the results are noticed positively.

We’re reluctant to post schedules for several reasons, for example, we’re recently been working on Kit 8, 9 and 10 for the 2” Burrell. We chose to start working on all three kits because of some casting delays with items in kit 8. There is a lot of machining on items in Kit 10, so it also made sense to start these earlier. The Kit 8 items arrived earlier than we were led to believe, so we’ve continued with the items started for Kits 9 and 10 but have now switched our priority back to Kit 8.

Another example is that we recently started machining a batch of cylinders for our DCC. The batch was 22 off, although we had asked the foundry for 35 off. The batch was started because the foundry couldn’t give us a reasonable idea of when new supplies would be provided. We started with 22 and that would have met our current customer commitments plus two spares. 12 of that batch failed due to casting issues after about four weeks machining.

We’ve been waiting for ages to get loads of casting for the second batch of 6” Fodens. These arrived a couple of weeks ago. They were horrible and we rejected the lot.

What I’m trying to portray is that whilst we do try to plan our production it is also very reactive, that’s why we will continue to encourage Craig to post many photos of items in production to at least show that we are still here and working hard to get kits shipped. The emphasis being placed on getting back to regular monthly shipments.

I guess it’s worth going through a few of the actions that we’ve already put in place and some that are imminent.

Our new stock and ordering system is still our main priority, it’s still early days but we have now loaded the 4 ½” Foden and 4” DCC stock balances. Our ordering system is still being developed but at least we can see where some of the holes are, at least for the long lead time items. It’s already highlighted a few areas that would have otherwise caught us out.

Orders have been placed for all boiler barrels and steel plate for all our boiler requirements. We already have everything for the 6” Fodens, the new orders are for SCC’s and DCC’s. In fact the laser cut plates have already arrived and Craig should be posting a few photos of them being weld prepped. Not a very exciting operation but it has to be done.

We’re increasing the quantities of items being made. For example we’ve just ordered sufficient material to produce 100 off 2” Burrell Cylinders. We’re doing this to reduce the amount of time used to set the various machining operations. We need to be cautious about it though because we don’t want to tie all our cash up in stock or indeed run out of space to store it. In the short term though, this has a detrimental effect because it increases our production time so it is a fine balance.

We’re combining, where practical, different manufacturing batches. Similar to the above but at least we have confirmed orders for these. For example we currently have two batches of 6” Fodens in production. We’re now making sufficient of all items in the first batch to satisfy the second batch as well.

We’re looking at existing stock levels and starting to ship where these can make complete kits even though there may be insufficient for the entire batch. This will help counteract some of the current casting delays.

We’re placing orders for as many long lead time items as we can, but doing this on a priority basis so we hopefully receive orders in manageable amounts. This is where our new ordering system will be of major benefit.

I hope all of this helps. I’ll make sure that Craig posts more photos than he’s done of late, so at least you can see what we’re working on.

Regards

Steve

It’s not that we’ve got anything to hide, we’re just concerned that it would add a lot of confusion and potentially raise expectations that are not delivered. I’ll try to explain why further down this post.

By far the most important thing for us, is to be concentrating on us getting back on schedule with all our monthly deliveries, regardless of the model. There’s quite a few things that we’ve put in place to help this but it’s still going to be sometime before the results are noticed positively.

We’re reluctant to post schedules for several reasons, for example, we’re recently been working on Kit 8, 9 and 10 for the 2” Burrell. We chose to start working on all three kits because of some casting delays with items in kit 8. There is a lot of machining on items in Kit 10, so it also made sense to start these earlier. The Kit 8 items arrived earlier than we were led to believe, so we’ve continued with the items started for Kits 9 and 10 but have now switched our priority back to Kit 8.

Another example is that we recently started machining a batch of cylinders for our DCC. The batch was 22 off, although we had asked the foundry for 35 off. The batch was started because the foundry couldn’t give us a reasonable idea of when new supplies would be provided. We started with 22 and that would have met our current customer commitments plus two spares. 12 of that batch failed due to casting issues after about four weeks machining.

We’ve been waiting for ages to get loads of casting for the second batch of 6” Fodens. These arrived a couple of weeks ago. They were horrible and we rejected the lot.

What I’m trying to portray is that whilst we do try to plan our production it is also very reactive, that’s why we will continue to encourage Craig to post many photos of items in production to at least show that we are still here and working hard to get kits shipped. The emphasis being placed on getting back to regular monthly shipments.

I guess it’s worth going through a few of the actions that we’ve already put in place and some that are imminent.

Our new stock and ordering system is still our main priority, it’s still early days but we have now loaded the 4 ½” Foden and 4” DCC stock balances. Our ordering system is still being developed but at least we can see where some of the holes are, at least for the long lead time items. It’s already highlighted a few areas that would have otherwise caught us out.

Orders have been placed for all boiler barrels and steel plate for all our boiler requirements. We already have everything for the 6” Fodens, the new orders are for SCC’s and DCC’s. In fact the laser cut plates have already arrived and Craig should be posting a few photos of them being weld prepped. Not a very exciting operation but it has to be done.

We’re increasing the quantities of items being made. For example we’ve just ordered sufficient material to produce 100 off 2” Burrell Cylinders. We’re doing this to reduce the amount of time used to set the various machining operations. We need to be cautious about it though because we don’t want to tie all our cash up in stock or indeed run out of space to store it. In the short term though, this has a detrimental effect because it increases our production time so it is a fine balance.

We’re combining, where practical, different manufacturing batches. Similar to the above but at least we have confirmed orders for these. For example we currently have two batches of 6” Fodens in production. We’re now making sufficient of all items in the first batch to satisfy the second batch as well.

We’re looking at existing stock levels and starting to ship where these can make complete kits even though there may be insufficient for the entire batch. This will help counteract some of the current casting delays.

We’re placing orders for as many long lead time items as we can, but doing this on a priority basis so we hopefully receive orders in manageable amounts. This is where our new ordering system will be of major benefit.

I hope all of this helps. I’ll make sure that Craig posts more photos than he’s done of late, so at least you can see what we’re working on.

Regards

Steve

Last edited by Steam Traction World on Thu 02 Oct 2014, 2:05 pm; edited 1 time in total (Reason for editing : spelling!)

Re: september production photos...

Re: september production photos...

Steam Traction World wrote:

Another example is that we recently started machining a batch of cylinders for our DCC. The batch was 22 off, although we had asked the foundry for 35 off. The batch was started because the foundry couldn’t give us a reasonable idea of when new supplies would be provided. We started with 22 and that would have met our current customer commitments plus two spares. 12 of that batch failed due to casting issues after about four weeks machining.

What a nightmare and a waste of time for you

LiveSteam- Number of posts : 788

Location : Hampshire

Registration date : 2013-09-08

Re: september production photos...

Re: september production photos...

I think most of us would prefer to "have it right" & suffer the delays, rather than have it on time & have problems to sort out later!! There's nothing more "trying" than having to (for example) return a cylinder block after you've spent ages fitting it, when a problem comes to light, as I & a few others will confirm!! It's a lot of work for us & a lot of wasted time & expense for STW!!..... I think STW go to a lot of trouble to do the best for their customers, at least that's my experience & most others on the forum would I think agree!!

Regards,

Tony

Regards,

Tony

Tony King- Number of posts : 856

Age : 69

Location : scotland

Registration date : 2008-10-31

Re: september production photos...

Re: september production photos...

Thanks for the update Steve. Put me in the 'have it right' and suffer the delays camp, rather wait and be impressed than on time and disappointed. Excited to hear boilers are in progress - steam is on the way! I'm working hard to get everything ready to bolt on when it turns up (not doing a very good job of keeping up so far).

ChriX- Number of posts : 90

Age : 39

Location : Cornwall, UK

Registration date : 2012-06-22

Similar topics

Similar topics» July, August, September Production photos...

» July, August, September 2019 production photos.

» July/August/September 2017 production photos (new image host)

» July/August/September 2018 production photo

» General Production update SEPTEMBER 2013

» July, August, September 2019 production photos.

» July/August/September 2017 production photos (new image host)

» July/August/September 2018 production photo

» General Production update SEPTEMBER 2013

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum