2" Burrell Kit 20

+5

TonyT

northburrell

malcolm

hughb

Steam Traction World

9 posters

Page 1 of 2

Page 1 of 2 • 1, 2

2" Burrell Kit 20

2" Burrell Kit 20

Hi 2" Burrell Builders,

We have now made good progress on this kit. A delivery before the end of March is still expected.

Regards

Dean & Steve

We have now made good progress on this kit. A delivery before the end of March is still expected.

Regards

Dean & Steve

Re: 2" Burrell Kit 20

Re: 2" Burrell Kit 20

Hi

Is this the kit that I made some of the parts ??

{well loded the blanks and pushed the botton had fun}

{well loded the blanks and pushed the botton had fun}

Is this the kit that I made some of the parts ??

hughb- Number of posts : 575

Age : 54

Location : hertfordshire

Registration date : 2009-03-13

Reach Rod

Reach Rod

Hello,

I have today sorted out various bits and pieces supplied in Kit 20 and found that when I tried to slide the reach rod through the cutouts in the spectacle plates as per the insructions I found that it would only go through about halfway and then the offset in the rod fouled on the pipe and elbow from the boiler to the water guage. I am now hoping that if I unbolt the front spectacle plate this will give sufficient clearance to get the offset past the elbow as I do not look foreward to having to remove the cankshaft etc or the rear spectacle plate.

Has anyone else got this far and managed to get the reach rod in.

Malcolm.

I have today sorted out various bits and pieces supplied in Kit 20 and found that when I tried to slide the reach rod through the cutouts in the spectacle plates as per the insructions I found that it would only go through about halfway and then the offset in the rod fouled on the pipe and elbow from the boiler to the water guage. I am now hoping that if I unbolt the front spectacle plate this will give sufficient clearance to get the offset past the elbow as I do not look foreward to having to remove the cankshaft etc or the rear spectacle plate.

Has anyone else got this far and managed to get the reach rod in.

Malcolm.

malcolm- Number of posts : 18

Location : Holbeach, Lincolnshire [ 2" Burrell ]

Registration date : 2008-06-17

Re: 2" Burrell Kit 20

Re: 2" Burrell Kit 20

this is why i' kit collecting at the moment and not putting much together.. I think all this should go in at the same time as the hornplates I'm hoping that doing this saves me having to take things on and off again.. thaks for the heads up i'll get it all trial fitted with out the hornplates first..

northburrell- Number of posts : 197

Location : edinburgh

Registration date : 2008-10-15

Re: 2" Burrell Kit 20

Re: 2" Burrell Kit 20

Hi All

I've been outside in the sun today playing with the other woman and kit 20,and I've had a few problems to say the least.

Firstly,the reach rod will NOT pass through the spectacle plates whilst the R/H crank bearing housing is in place.Now this is a pain in the arse because you will have to take the whole motion apart to get the housing out

Secondly,the inside edge of the clevis that connects to the weighshaft will have to be filed away or else it will take big chunks of paint off the cleading.Now this is the time to see how easy it is to get the bloody cleading off again

Thirdly,the lower part of the water gauge will have to be removed to get the reversing lever onto it's spigot,and then the spigot will have to be filed down to get the water gauge back in

On the plus side though,no probs with the blower,exhaust,or regulator

It seems a shame that all the reversing lever gubbins will have to come out again to fit the diff and gears,as it is very fiddley to get it all in place and working smoothly only to take it all apart.

You have been warned

Cheer's Tony

I've been outside in the sun today playing with the other woman and kit 20,and I've had a few problems to say the least.

Firstly,the reach rod will NOT pass through the spectacle plates whilst the R/H crank bearing housing is in place.Now this is a pain in the arse because you will have to take the whole motion apart to get the housing out

Secondly,the inside edge of the clevis that connects to the weighshaft will have to be filed away or else it will take big chunks of paint off the cleading.Now this is the time to see how easy it is to get the bloody cleading off again

Thirdly,the lower part of the water gauge will have to be removed to get the reversing lever onto it's spigot,and then the spigot will have to be filed down to get the water gauge back in

On the plus side though,no probs with the blower,exhaust,or regulator

It seems a shame that all the reversing lever gubbins will have to come out again to fit the diff and gears,as it is very fiddley to get it all in place and working smoothly only to take it all apart.

You have been warned

Cheer's Tony

TonyT- Number of posts : 134

Age : 56

Location : Truro,Cornwall. (2" Burrell)

Registration date : 2008-06-17

Re: 2" Burrell Kit 20

Re: 2" Burrell Kit 20

HI TONY,

JUST A QUICK QUESTION, WHICH MIGHT SEEM WEIRD !, BUT WOULD THE REACH ROD PASS THROUGH OK IF THE TENDER WAS STILL NOT FITTED.

WE HAVE NOT LOOKED AT FITTING ANY OF KIT 20, AS OF THIS MOMENT, SO IF THAT IS A TOTAL NUMPTY QUESTION, SORRY IN ADVANCE

REGARDS

BUNGLE

JUST A QUICK QUESTION, WHICH MIGHT SEEM WEIRD !, BUT WOULD THE REACH ROD PASS THROUGH OK IF THE TENDER WAS STILL NOT FITTED.

WE HAVE NOT LOOKED AT FITTING ANY OF KIT 20, AS OF THIS MOMENT, SO IF THAT IS A TOTAL NUMPTY QUESTION, SORRY IN ADVANCE

REGARDS

BUNGLE

BUNGLE- Number of posts : 232

Age : 66

Location : HERTS (2" BURRELL)

Registration date : 2008-06-17

Re: 2" Burrell Kit 20

Re: 2" Burrell Kit 20

HI guysBUNGLE wrote:HI TONY,

JUST A QUICK QUESTION, WHICH MIGHT SEEM WEIRD !, BUT WOULD THE REACH ROD PASS THROUGH OK IF THE TENDER WAS STILL NOT FITTED.

WE HAVE NOT LOOKED AT FITTING ANY OF KIT 20, AS OF THIS MOMENT, SO IF THAT IS A TOTAL NUMPTY QUESTION, SORRY IN ADVANCE

REGARDS

BUNGLE

my Tender is off at the mo I was going to fit no 20 with it off at W/E but did the gardening

This sounds like I now have a lot to do over easter

Thanks for the heads up

hughb- Number of posts : 575

Age : 54

Location : hertfordshire

Registration date : 2009-03-13

Re: 2" Burrell Kit 20

Re: 2" Burrell Kit 20

Hi Bungle

You're not being a numpty asking that question,it's a fair one.

The reach rod lays between the water gauge pipe coming off the boiler and the R/H hornplate,and under the R/H bearing housing.Taking the tender off might give you a bit more room but I don't think it will help that much.It's all a tight fit and the webbing on the bearing housing stops the rod from going through.

I had a chat with Hughb on the phone last week and he was telling me that when he took STW up on their word on spending the day at STW Towers,he helped in making some of the parts for kit 20 and one of the probs on the control model was getting the reach rod through the spectacle plates,and that they took the R/H bearing housing out.That's why I done it that way,almost taking advice from the machine floor at STW.

Perhaps this information should have been included with the kit 20 destructions!

I've just had another look at mine and you might be able to get it through if you undo the front spectacle plate and raise it like Malcolm suggested in an earlier post but be prepared for a bit of strip down.

Does anyone else have any thoughts on this?

cheer's Tony

You're not being a numpty asking that question,it's a fair one.

The reach rod lays between the water gauge pipe coming off the boiler and the R/H hornplate,and under the R/H bearing housing.Taking the tender off might give you a bit more room but I don't think it will help that much.It's all a tight fit and the webbing on the bearing housing stops the rod from going through.

I had a chat with Hughb on the phone last week and he was telling me that when he took STW up on their word on spending the day at STW Towers,he helped in making some of the parts for kit 20 and one of the probs on the control model was getting the reach rod through the spectacle plates,and that they took the R/H bearing housing out.That's why I done it that way,almost taking advice from the machine floor at STW.

Perhaps this information should have been included with the kit 20 destructions!

I've just had another look at mine and you might be able to get it through if you undo the front spectacle plate and raise it like Malcolm suggested in an earlier post but be prepared for a bit of strip down.

Does anyone else have any thoughts on this?

cheer's Tony

TonyT- Number of posts : 134

Age : 56

Location : Truro,Cornwall. (2" Burrell)

Registration date : 2008-06-17

Re: 2" Burrell Kit 20

Re: 2" Burrell Kit 20

Yes.. collect all the kits first then build the model  I kinda knew this would happen so i'm just waiting for the gears. diff and winch etc.. O and the water pump as i can see this being a sod to fit aswell..

I kinda knew this would happen so i'm just waiting for the gears. diff and winch etc.. O and the water pump as i can see this being a sod to fit aswell..

Or STW could build a model and test it, iron out any things wrong then sell it.. that's how other steam engine kit makers do it (wont name the company!!).. I dont really like this build as you get a kit stuff as this model has had no quality testing done on the final product. I would only build another model from them if they started doing this..

hope you dont have to take too much off to get to fit and mind that paint..

Also how are you doing your lining is it tape stuck on??

Or STW could build a model and test it, iron out any things wrong then sell it.. that's how other steam engine kit makers do it (wont name the company!!).. I dont really like this build as you get a kit stuff as this model has had no quality testing done on the final product. I would only build another model from them if they started doing this..

hope you dont have to take too much off to get to fit and mind that paint..

Also how are you doing your lining is it tape stuck on??

Last edited by northburrell on Mon 06 Apr 2009, 11:23 pm; edited 1 time in total

northburrell- Number of posts : 197

Location : edinburgh

Registration date : 2008-10-15

Re: 2" Burrell Kit 20

Re: 2" Burrell Kit 20

I see where you're coming from Northburrell,but as I have more than enough time at the moment I don't mind too much.In a way,it is handy because I caught the paint on the crank when I was fitting the straps.

As for the boiler cleading,I should be able to touch that up without taking it off.

Also all my lining has been painted on

cheer's Tony

As for the boiler cleading,I should be able to touch that up without taking it off.

Also all my lining has been painted on

cheer's Tony

TonyT- Number of posts : 134

Age : 56

Location : Truro,Cornwall. (2" Burrell)

Registration date : 2008-06-17

Re: 2" Burrell Kit 20

Re: 2" Burrell Kit 20

lining looks nice mate was wondering how you did it so fast.. I dropped a bolt on my cleading and chipped it, I just touched it back in and polished it back, you cant even see it now..

good luck with it all and let us know how it goes...

good luck with it all and let us know how it goes...

northburrell- Number of posts : 197

Location : edinburgh

Registration date : 2008-10-15

Re: 2" Burrell Kit 20

Re: 2" Burrell Kit 20

TONY,

MANY THANKS FOR THAT INFO, OUR TENDER IS STILL OFF AT THE MOMENT (FOR MANY REASONS, BUT NOT STW's FAULT) SO WONDERED IF THAT MAY HAVE HELPED. BIT PI**ED ABOUT HAVING TO TAKE THE BEARING HOUSING BACK OUT, GOT THE PAINT NICE, NOW GOING TO BALLS IT UP

REGARDS

BUNGLE

MANY THANKS FOR THAT INFO, OUR TENDER IS STILL OFF AT THE MOMENT (FOR MANY REASONS, BUT NOT STW's FAULT) SO WONDERED IF THAT MAY HAVE HELPED. BIT PI**ED ABOUT HAVING TO TAKE THE BEARING HOUSING BACK OUT, GOT THE PAINT NICE, NOW GOING TO BALLS IT UP

REGARDS

BUNGLE

Last edited by BUNGLE on Tue 07 Apr 2009, 8:14 am; edited 1 time in total (Reason for editing : MISSING WORD)

BUNGLE- Number of posts : 232

Age : 66

Location : HERTS (2" BURRELL)

Registration date : 2008-06-17

Re: 2" Burrell Kit 20

Re: 2" Burrell Kit 20

Hi All

Seeing all the negative comments about fitting the reach rod is obviously quite concerning for us, so I removed the reach rod from our control model and refitted it without having to remove anything.

Hugh mentioned in one of his posts that he remembered us removing the RH bearing housing when he was with us for the day. What he probably wasn't aware of is that this was a prototype part that was being tested before the proper laser cut items were ordered. We therefore needed to check all clearances which is why it was removed.

There is certainly not alot of clearance around any of the items because there's alot going on in this area and I didn't want to make the reach rod too thin. This would make fitting it easier but it wouldn't be very good in service.

The way I fitted the reach rod was to pass it at 90 deg to its normal orientation through the cut out in the rear spectacle plate. Once it passes under the water gauge pipe I then turned it back through 90 deg so its in the correct orientation. It then passed all the way through to the valve gear without any problems.

Each model may vary slightly, particularly how the WG pipe is formed and it may be this that's causing a problem. If this is the cause then it should be possible to 'tweak' the pipe slightly. The copper will still be quite soft from when the fittings were silver soldered.

We also didn't have to alter the lower WG to fit the reversing lever spigot. At the very worst all you would need to do is remove the valve part of the fitting. I take it that the valve was actually closed. It may be that your WG is protruding too far into the tender area.

Hope this helps

Regards

Steve

Seeing all the negative comments about fitting the reach rod is obviously quite concerning for us, so I removed the reach rod from our control model and refitted it without having to remove anything.

Hugh mentioned in one of his posts that he remembered us removing the RH bearing housing when he was with us for the day. What he probably wasn't aware of is that this was a prototype part that was being tested before the proper laser cut items were ordered. We therefore needed to check all clearances which is why it was removed.

There is certainly not alot of clearance around any of the items because there's alot going on in this area and I didn't want to make the reach rod too thin. This would make fitting it easier but it wouldn't be very good in service.

The way I fitted the reach rod was to pass it at 90 deg to its normal orientation through the cut out in the rear spectacle plate. Once it passes under the water gauge pipe I then turned it back through 90 deg so its in the correct orientation. It then passed all the way through to the valve gear without any problems.

Each model may vary slightly, particularly how the WG pipe is formed and it may be this that's causing a problem. If this is the cause then it should be possible to 'tweak' the pipe slightly. The copper will still be quite soft from when the fittings were silver soldered.

We also didn't have to alter the lower WG to fit the reversing lever spigot. At the very worst all you would need to do is remove the valve part of the fitting. I take it that the valve was actually closed. It may be that your WG is protruding too far into the tender area.

Hope this helps

Regards

Steve

Re: 2" Burrell Kit 20

Re: 2" Burrell Kit 20

Hi Steve and All

Wow I'm sorry if any of my comments have been taken in a negative way,they weren't meant that way,just trying to offer a bit of advice to other builder's

I'm sorry if any of my comments have been taken in a negative way,they weren't meant that way,just trying to offer a bit of advice to other builder's

Anyhow now I'm here,I've got the reach rod in place,reversing lever on,everything else back in place.Turning the engine over with the flywheel,everything feels smooth and a nice "woosh" sound

Here's a few pics:

cheer's for now

Tony

Wow

Anyhow now I'm here,I've got the reach rod in place,reversing lever on,everything else back in place.Turning the engine over with the flywheel,everything feels smooth and a nice "woosh" sound

Here's a few pics:

cheer's for now

Tony

Last edited by TonyT on Wed 08 Apr 2009, 12:16 am; edited 1 time in total (Reason for editing : Spelling)

TonyT- Number of posts : 134

Age : 56

Location : Truro,Cornwall. (2" Burrell)

Registration date : 2008-06-17

Re: 2" Burrell Kit 20

Re: 2" Burrell Kit 20

Hi Tony

What a good job you're doing. Looks really smart. See what you mean about the reversing spigot. As I said in my earlier post ours is quite clear of the WG. I wonder why there's a difference?

I'm probably being over sensitive, its an age thing, now I'm in my thirties ...****!!!!!!!

...****!!!!!!!

Regards

Steve

What a good job you're doing. Looks really smart. See what you mean about the reversing spigot. As I said in my earlier post ours is quite clear of the WG. I wonder why there's a difference?

I'm probably being over sensitive, its an age thing, now I'm in my thirties

...****!!!!!!!

...****!!!!!!! Regards

Steve

Re: 2" Burrell Kit 20

Re: 2" Burrell Kit 20

Steve,

Didn't you mean 'now you're in your eighties!' cos that's how we feel some days! lol. Nice to see one of us is being constructive and working late at night answering questions on the forum. I'm glad you can multi task cos as well as the forum tonight, you must be also working on the new designs in between the most important thing on an evening 'having a beer'. As a single tasker i'm just doing the latter!

I agree with Steve, Tony your engine really is starting to look very smart indeed. Keep up the good work everyone.

All the best

Dean

Didn't you mean 'now you're in your eighties!' cos that's how we feel some days! lol. Nice to see one of us is being constructive and working late at night answering questions on the forum. I'm glad you can multi task cos as well as the forum tonight, you must be also working on the new designs in between the most important thing on an evening 'having a beer'. As a single tasker i'm just doing the latter!

I agree with Steve, Tony your engine really is starting to look very smart indeed. Keep up the good work everyone.

All the best

Dean

Re: 2" Burrell Kit 20

Re: 2" Burrell Kit 20

Looking good tony..

I dont want this to sound bad but are you going to clean up the cutter marks on the valve gear lifting links and the excentric strap arms.. i'm taking great care in filing the parts, rounding the corners off,sanding them, it just makes the parts look nicer.. for the lifting links i used some fine wet an dry sand paper only took about 10 mins to do one link and i have a mirror like finish. I have done the same for all bare metal parts that are on show.

Look carefully at your valve handles, there's lots of flashing left in the spokes from casting and if you use a small round file you can quickly remove this. It Just makes them look a little nicer.. I think i might be taking too long over cleaning up my parts

I'm even taking the time to file off the numbers on the heads of the bolts that hold the bearing housings and spec plates on.. looks a hell of allot cleaner when painted up...

I just thought i'd ask and mention it as you could still take those bits off and do it if you wanted to.

no offence ment by this..

I dont want this to sound bad but are you going to clean up the cutter marks on the valve gear lifting links and the excentric strap arms.. i'm taking great care in filing the parts, rounding the corners off,sanding them, it just makes the parts look nicer.. for the lifting links i used some fine wet an dry sand paper only took about 10 mins to do one link and i have a mirror like finish. I have done the same for all bare metal parts that are on show.

Look carefully at your valve handles, there's lots of flashing left in the spokes from casting and if you use a small round file you can quickly remove this. It Just makes them look a little nicer.. I think i might be taking too long over cleaning up my parts

I'm even taking the time to file off the numbers on the heads of the bolts that hold the bearing housings and spec plates on.. looks a hell of allot cleaner when painted up...

I just thought i'd ask and mention it as you could still take those bits off and do it if you wanted to.

no offence ment by this..

Last edited by northburrell on Wed 08 Apr 2009, 11:47 pm; edited 7 times in total

northburrell- Number of posts : 197

Location : edinburgh

Registration date : 2008-10-15

Re: 2" Burrell Kit 20

Re: 2" Burrell Kit 20

STEVE,

THIRTIES ! SORRY MATE YOU AIN'T WORN WELL

SERIOUSLY, CALM DOWN, TONY COMMENTS HAVE BEEN HELPFUL TO ALL OF US (ALONG WITH YOUR SUGGESTION FOR FITTING THE REACH) THIS IS WHAT THE FORUMS ABOUT, RAISING PROBS, AND SORTING THEM OUT BETWEEN US.

WE'LL PUT IT DOWN TO YOUR AGE, (I'M MUCH OLDER, SO CAN'T SAY TO MUCH !!), AND A BAD DAY

TODAYS ANOTHER DAY !

REGARDS

BUNGLE

THIRTIES ! SORRY MATE YOU AIN'T WORN WELL

SERIOUSLY, CALM DOWN, TONY COMMENTS HAVE BEEN HELPFUL TO ALL OF US (ALONG WITH YOUR SUGGESTION FOR FITTING THE REACH) THIS IS WHAT THE FORUMS ABOUT, RAISING PROBS, AND SORTING THEM OUT BETWEEN US.

WE'LL PUT IT DOWN TO YOUR AGE, (I'M MUCH OLDER, SO CAN'T SAY TO MUCH !!), AND A BAD DAY

TODAYS ANOTHER DAY !

REGARDS

BUNGLE

Last edited by BUNGLE on Wed 08 Apr 2009, 10:27 pm; edited 1 time in total

BUNGLE- Number of posts : 232

Age : 66

Location : HERTS (2" BURRELL)

Registration date : 2008-06-17

2" Burrell Kit 20

2" Burrell Kit 20

Hello,

I eventually found that I could fit the reach rod through the spectacle plates with the tender etc fitted. by removing the the diff lock boss from the 2nd shaft tube to give more room to manoeuver the rod into place.

I also found that the weighshaft end clevis was fouling the boiler cladding and needed filing off.

I have also had to file the top of the curved section of the reach rod as I found that in the full forward position the rod was hitting the bottom of the bearing housing.

Finally I have found that the wheel of the water guage valve is hitting the reversing lever but this appears to be due to the tapping in the boiler not being square thus angling the valve towards the hornplate but I have overcome this by making up an extension to the valve spindle to move the wheel past the reversing lever.

Malcolm.

I eventually found that I could fit the reach rod through the spectacle plates with the tender etc fitted. by removing the the diff lock boss from the 2nd shaft tube to give more room to manoeuver the rod into place.

I also found that the weighshaft end clevis was fouling the boiler cladding and needed filing off.

I have also had to file the top of the curved section of the reach rod as I found that in the full forward position the rod was hitting the bottom of the bearing housing.

Finally I have found that the wheel of the water guage valve is hitting the reversing lever but this appears to be due to the tapping in the boiler not being square thus angling the valve towards the hornplate but I have overcome this by making up an extension to the valve spindle to move the wheel past the reversing lever.

Malcolm.

malcolm- Number of posts : 18

Location : Holbeach, Lincolnshire [ 2" Burrell ]

Registration date : 2008-06-17

Re: 2" Burrell Kit 20

Re: 2" Burrell Kit 20

There's a funny smell around here, BS me thinks

Vapor- Number of posts : 384

Age : 114

Location : Isle of Wight (2" Burrell & 5" Duchess ex MW)

Registration date : 2008-06-18

Re: 2" Burrell Kit 20

Re: 2" Burrell Kit 20

Yep my taping in my boiler for the bottom water gauge is also on the piss so it looks like i'm going to have to make an extension.. I might just change the handle on the valve as I have smaller ones from my loco's but until it's all fitted up I can really no for sure..

Malcom how did you make up your extension was it fairly easy? I was thinking I might silver solder a piece on the end then re thread it.

Malcom how did you make up your extension was it fairly easy? I was thinking I might silver solder a piece on the end then re thread it.

northburrell- Number of posts : 197

Location : edinburgh

Registration date : 2008-10-15

2" Burrell Kit 20

2" Burrell Kit 20

Hello,

To extend the the water guage valve shaft I used a 2BA screw with the head cut off and to the reqired length. I then drilled this through the centre lengthwise and tapped it through at 8BA which is the thread on the valve spindle. this extension was then screwed onto the valve spindle and locked with an 8BA nut. Into the other end of the extension I screwed in an 8BA screw with the head removed and onto this screwed on the handwheel and locknut. As I have now found that this idea works I shall either make up a new one using a piece of plain brass rod if I can find some, or look at electrical spares as these items used to be used to mount printed circuit boards but I am not sure if they went as small as 8BA. If I do find a manufactured item I will add another post to the forum

Malcolm,

To extend the the water guage valve shaft I used a 2BA screw with the head cut off and to the reqired length. I then drilled this through the centre lengthwise and tapped it through at 8BA which is the thread on the valve spindle. this extension was then screwed onto the valve spindle and locked with an 8BA nut. Into the other end of the extension I screwed in an 8BA screw with the head removed and onto this screwed on the handwheel and locknut. As I have now found that this idea works I shall either make up a new one using a piece of plain brass rod if I can find some, or look at electrical spares as these items used to be used to mount printed circuit boards but I am not sure if they went as small as 8BA. If I do find a manufactured item I will add another post to the forum

Malcolm,

malcolm- Number of posts : 18

Location : Holbeach, Lincolnshire [ 2" Burrell ]

Registration date : 2008-06-17

Re: 2" Burrell Kit 20

Re: 2" Burrell Kit 20

Hi guys ok now this is not funny at all .

First of all Love your engine Tony well done looking good .

Pluss all of your writups thanks ....

As for me well NOt good must stop digging for old bottles /Caveing and shooting arrows ...Ho yes growing veg

AND get on with my engine ..

WELL DONE TO ALL THAT HAVE BEEN INVOLVED SO FAR

First of all Love your engine Tony well done looking good .

Pluss all of your writups thanks ....

As for me well NOt good must stop digging for old bottles /Caveing and shooting arrows ...Ho yes growing veg

AND get on with my engine ..

WELL DONE TO ALL THAT HAVE BEEN INVOLVED SO FAR

hughb- Number of posts : 575

Age : 54

Location : hertfordshire

Registration date : 2009-03-13

Re: 2" Burrell Kit 20

Re: 2" Burrell Kit 20

I just made a new handle from the original one.

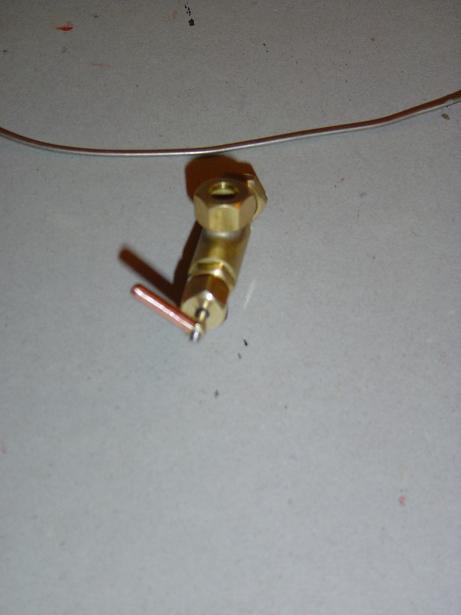

Do the valve up tight and mark the spoke that is pointing vertical up. take off the handle and trim the other spokes off. dont worry too much about cleaning it up but be carfull around the spoke you marked and dont trim it off or break it!!. this will be filed and to fit down the copper tube. take some copper pipe counter sink one hole in one end and round the other end off. here are the parts.

Trial fit with easy flow in the background..

silver solder with easy flow and fill the other end with solder. looks a bit crappy but give it a good clean

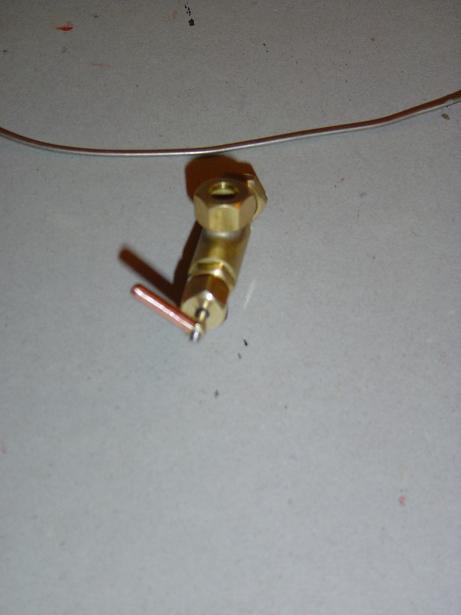

Finished valve and handle after filing and cleaning.

The valve opens about 70% at 3/4 of a turn open. more than enough for a blow down that wont be used too much. Now just some more cleaning up and maybe a paint..

thats what i'v done just wanted to share it.

Do the valve up tight and mark the spoke that is pointing vertical up. take off the handle and trim the other spokes off. dont worry too much about cleaning it up but be carfull around the spoke you marked and dont trim it off or break it!!. this will be filed and to fit down the copper tube. take some copper pipe counter sink one hole in one end and round the other end off. here are the parts.

Trial fit with easy flow in the background..

silver solder with easy flow and fill the other end with solder. looks a bit crappy but give it a good clean

Finished valve and handle after filing and cleaning.

The valve opens about 70% at 3/4 of a turn open. more than enough for a blow down that wont be used too much. Now just some more cleaning up and maybe a paint..

thats what i'v done just wanted to share it.

Last edited by northburrell on Thu 09 Apr 2009, 12:23 pm; edited 4 times in total

northburrell- Number of posts : 197

Location : edinburgh

Registration date : 2008-10-15

Re: 2" Burrell Kit 20

Re: 2" Burrell Kit 20

HUmmmmm

Thanks as I have not got that far at all .

Looks good well done

Thanks as I have not got that far at all .

Looks good well done

hughb- Number of posts : 575

Age : 54

Location : hertfordshire

Registration date : 2009-03-13

Page 1 of 2 • 1, 2

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum