Frederick SRL(S)

+26

LiveSteam

He Who Must Not Be Blamed

the governer

Brian M

ChriX

Heavyhaul

MrStationHouse

HStannard

Kiwiconnection

Steam Traction World

the coleman

ejparrott

SSGR

Adam Brown

Kevster

highpressure

mikero

Flasback

bjwlancashire

Richard

lynnr

IanL

Steve Traill

Robfishman

Tony King

Tim Watson

30 posters

Page 10 of 12

Page 10 of 12 •  1, 2, 3 ... 9, 10, 11, 12

1, 2, 3 ... 9, 10, 11, 12

Compensating gear

Compensating gear

The compensating gear (differential) on "Frederick" has never been as smooth or as quiet as I would like. It needed extensive packings between the gears, which allowed them to be noisy and prone to wear in various components. After having problems last year, I re-profiled by hand the outer bevel (large gear) which made things a bit sweeter: however, the pinions (small gears) still really wanted to describe a larger radius than they were allowed. Recently, an increase in noise indicated that all was not well.

In the spring, Steve (Thetford Works) and I were looking at his collection of gears and determined that trimming 3mm off the pinion outer surface may be a solution, allowing the smaller diameter of the pinion to run on a larger radius (something I had considered back in December). Steve has done this on his engine.

So, yesterday I stripped out the hind near side wheel and trimmed the pinions. It is actually very simple to do, as the even-toothed pinions were conveniently held in my four jaw chuck on the lathe. The depth removed is effectively to where the angled edge meets the tooth form (this needs reinstating to allow the pinion to be moved out wards). There is a need for a 3mm wide inner bush to keep them in this outer position. On re-assembly, with thinner inter-bevel spacers, the whole assembly runs much sweeter. It can be turned with one finger and rumbles rather than clatters.

I will steam the engine next weekend, so we'll see how it moves. Sorry, no pictures as I was rushing to make use of the daylight and good weather outside. I also took the opportunity to make and fit a decent sized, flanged, holder pin for the damper rod.

Tim

In the spring, Steve (Thetford Works) and I were looking at his collection of gears and determined that trimming 3mm off the pinion outer surface may be a solution, allowing the smaller diameter of the pinion to run on a larger radius (something I had considered back in December). Steve has done this on his engine.

So, yesterday I stripped out the hind near side wheel and trimmed the pinions. It is actually very simple to do, as the even-toothed pinions were conveniently held in my four jaw chuck on the lathe. The depth removed is effectively to where the angled edge meets the tooth form (this needs reinstating to allow the pinion to be moved out wards). There is a need for a 3mm wide inner bush to keep them in this outer position. On re-assembly, with thinner inter-bevel spacers, the whole assembly runs much sweeter. It can be turned with one finger and rumbles rather than clatters.

I will steam the engine next weekend, so we'll see how it moves. Sorry, no pictures as I was rushing to make use of the daylight and good weather outside. I also took the opportunity to make and fit a decent sized, flanged, holder pin for the damper rod.

Tim

Tim Watson- Number of posts : 585

Location : Herts

Registration date : 2008-07-02

Re: Frederick SRL(S)

Re: Frederick SRL(S)

This surely indicates the gears have been designed and/or machined incorrectly.

They should fit properly in the first instance and certaintly not show signs of wear already.

its all a bit worrying.

Kev

They should fit properly in the first instance and certaintly not show signs of wear already.

its all a bit worrying.

Kev

Kevster- Number of posts : 424

Location : Hertfordshire 4 inch; DCC road loco

Registration date : 2011-01-27

Re: Frederick SRL(S)

Re: Frederick SRL(S)

Kev

It wasn't that the gears themselves were wearing, I just prefer things to be quiet - the whole assembly rarely kicks in to use. I suspect I was unlucky with the outer bevel. The solution as suggested, which I think will work well, is straightforward. The Burrell design of compensating gear and winch on the back axle was not one of their best, which is why the later engines were fitted with a double drive. Once components such as the bushes begin to bed in with the single drive design there is a need to take up the slack on the packings: I know others have found this.

If individuals want their bevel gears modified (after some trials of the prototype) I would be happy to do this.

Tim

It wasn't that the gears themselves were wearing, I just prefer things to be quiet - the whole assembly rarely kicks in to use. I suspect I was unlucky with the outer bevel. The solution as suggested, which I think will work well, is straightforward. The Burrell design of compensating gear and winch on the back axle was not one of their best, which is why the later engines were fitted with a double drive. Once components such as the bushes begin to bed in with the single drive design there is a need to take up the slack on the packings: I know others have found this.

If individuals want their bevel gears modified (after some trials of the prototype) I would be happy to do this.

Tim

Tim Watson- Number of posts : 585

Location : Herts

Registration date : 2008-07-02

Diff gears

Diff gears

It was 8mm I took off the back of the pinions and made an 8mm spacer to hold the pinion in position. This effectively moved the pinion out 8mm. This dimension may vary, it can be checked by rolling the pinion around the gear wheel and see where it is happy.

Steve Traill- Number of posts : 800

Age : 67

Location : Illogan Redruth Cornwall

Registration date : 2008-06-29

NTET 60 road run

NTET 60 road run

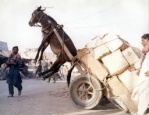

Had a most enjoyable day at the NTET road run today. Steve Trail and I arrived Friday evening and then set off at 0930 the next day. We took the medium length route which was originally 28 miles but was probably nearer 30, because of a diversion due to a road closure. We easily kept up with the full size road locos and engines on this run. Most of the miniatures went on the shorter routes which also included many rollers: these can be very frustrating to follow. Frederick stayed in high wheel all the way and used just one bag of steam coal and not a lot of water. We cruised at between 6-8 mph depending on road conditions and returned to Shuttleworth College by 1500.

Frederick after 30 miles.

Tim

Frederick after 30 miles.

Tim

Tim Watson- Number of posts : 585

Location : Herts

Registration date : 2008-07-02

Re: Frederick SRL(S)

Re: Frederick SRL(S)

Wonderful!

lynnr- Number of posts : 3242

Age : 56

Location : Highland, 4inch showman

Registration date : 2010-08-06

30 mile run

30 mile run

What a great day out, perfect weather, engine running sweetly, no traffic jams. We would have been quicker if the road surface had been a bit smoother!

Good meal in the evening,

Thanks for a great day Tim

Good meal in the evening,

Thanks for a great day Tim

Steve Traill- Number of posts : 800

Age : 67

Location : Illogan Redruth Cornwall

Registration date : 2008-06-29

Let there be light(a)

Let there be light(a)

After a bit of a delay I have at last got round to making the brackets to support the 'King of the Road' lamps that i used to have on Madeline. The original fixings I made for the front did not look right and made the lamps very vulnerable. These new brackets are taken from the rearmost bolt of the dynamo platform on the dynamo bracket. They are bent up from steel strip with a gusset of silver solder in the angles where the corners were notched: even so, the steel angles were formed red hot.

The abutting of the bracket into the corner of the platform and its proximity to the middle bolt should prevent any rotation.

The lights are inside the arc of the wheels so should not get caught when traversing rough ground, whilst they are far enough out to illuminate past the front of the dynamo bracket.

The lamps are locked on to the bracket with a 4BA Allan bolt, tapped into the bracket itself. These brackets obviously will be painted.

The next lighting job will be to mount the centre headlight that I have acquired. This is a CREE XM-L 1200 lumen bike light, I want to mount this under the dynamo bracket at the front, in the midline. This will light the way when returning from the beer tent in the dark and also perhaps be used when on the road. It is bright enough to bring down Zeppelins!

I'll take some side view pictures at Portsmouth Historic Dockyard this weekend.

Tim

The abutting of the bracket into the corner of the platform and its proximity to the middle bolt should prevent any rotation.

The lights are inside the arc of the wheels so should not get caught when traversing rough ground, whilst they are far enough out to illuminate past the front of the dynamo bracket.

The lamps are locked on to the bracket with a 4BA Allan bolt, tapped into the bracket itself. These brackets obviously will be painted.

The next lighting job will be to mount the centre headlight that I have acquired. This is a CREE XM-L 1200 lumen bike light, I want to mount this under the dynamo bracket at the front, in the midline. This will light the way when returning from the beer tent in the dark and also perhaps be used when on the road. It is bright enough to bring down Zeppelins!

I'll take some side view pictures at Portsmouth Historic Dockyard this weekend.

Tim

Tim Watson- Number of posts : 585

Location : Herts

Registration date : 2008-07-02

Re: Frederick SRL(S)

Re: Frederick SRL(S)

Tim

I saw your request on TT for photos or drawings of centre mounted lights on engines. I have one picture which although it is taken in the 1950s shows His Lordship when owned by Tommy Albert with a large centre mounted electric light by the look of things. It might not be exactly what you wanted to help you but gives you an impression.

I saw your request on TT for photos or drawings of centre mounted lights on engines. I have one picture which although it is taken in the 1950s shows His Lordship when owned by Tommy Albert with a large centre mounted electric light by the look of things. It might not be exactly what you wanted to help you but gives you an impression.

bjwlancashire- Number of posts : 938

Location : Mellor, Lancashire

Registration date : 2010-09-07

Re: Frederick SRL(S)

Re: Frederick SRL(S)

Thanks Brian. That's what you call a well lit engine! Not quite the central front lamp I had in mind but in the right place. I may simply make the new lamp readily detachable and not worry too much about it's historical veracity.

Tim

Tim

Tim Watson- Number of posts : 585

Location : Herts

Registration date : 2008-07-02

Three Fredericks

Three Fredericks

My son took this rather nice picture in the Portsmouth Historic Dockyard at their Victorian Christmas do (the little Frederick is visible under the roof).

Best wishes to everyone for Christmas & the New Year!

Tim

Best wishes to everyone for Christmas & the New Year!

Tim

Tim Watson- Number of posts : 585

Location : Herts

Registration date : 2008-07-02

Improved hind wheel lubrication

Improved hind wheel lubrication

Way back in the early build stages I modified the two oil boxes over the hind axle to reduce the amount of oil by using a plumbing fitting. This has worked OK for the near side but has been pretty well completely inaccessible for the off side - both were susceptible to coal dust. I know that some other builders have moved the oil pots for the hind wheels higher up in the man stand.

After the SAC do at Old Warden last weekend I was not happy with the alignment of the water gauge (the glass was weeping a bit) and so decided to take it off to re-set it. This was an excellent opportunity to redo the offside hind oiler. I had some spare pipe fittings and made a larger oil pot to feed both the second and third shaft. This was fixed to the original bracket: I didn't want to replace this as it would have entailed taking of the wheel, gears and probably more besides! The hole on the top was made a little bigger to allow access to my specially adapted oil can nozzle. The fittings used are very tight to the injector pipe and needed a bit removing to snuggle in nicely.

The pipe runs down the nearside of the reversing linkage, straight into the front of the oil box, which needed a corner milling out to allow the cover to be removed. The cover also needed milling out to take the drainage pipe from the water gauge, and whilst that had been done previously, I made it a bit bigger to ease its removal.

The terminal end of the pipe is fixed to a T piece sliver soldered to the hole in the base of the oil box. This could have been a right angle fitting, but the T was all that was available. Quite useful, actually, as you can undo the plug end to check that oil is flowing.

This modification will make life so much easier and cleaner for oiling up. I will probably do a similar exercise on the nearside hind wheel oiler, but this one is less of a problem for access. If you are making a new engine, I would strongly recommend a similar type of modification BEFORE you get all the other stuff on your engine.

Tim

After the SAC do at Old Warden last weekend I was not happy with the alignment of the water gauge (the glass was weeping a bit) and so decided to take it off to re-set it. This was an excellent opportunity to redo the offside hind oiler. I had some spare pipe fittings and made a larger oil pot to feed both the second and third shaft. This was fixed to the original bracket: I didn't want to replace this as it would have entailed taking of the wheel, gears and probably more besides! The hole on the top was made a little bigger to allow access to my specially adapted oil can nozzle. The fittings used are very tight to the injector pipe and needed a bit removing to snuggle in nicely.

The pipe runs down the nearside of the reversing linkage, straight into the front of the oil box, which needed a corner milling out to allow the cover to be removed. The cover also needed milling out to take the drainage pipe from the water gauge, and whilst that had been done previously, I made it a bit bigger to ease its removal.

The terminal end of the pipe is fixed to a T piece sliver soldered to the hole in the base of the oil box. This could have been a right angle fitting, but the T was all that was available. Quite useful, actually, as you can undo the plug end to check that oil is flowing.

This modification will make life so much easier and cleaner for oiling up. I will probably do a similar exercise on the nearside hind wheel oiler, but this one is less of a problem for access. If you are making a new engine, I would strongly recommend a similar type of modification BEFORE you get all the other stuff on your engine.

Tim

Tim Watson- Number of posts : 585

Location : Herts

Registration date : 2008-07-02

Getting ready for the big run

Getting ready for the big run

'Frederick' is going to have a spare grate (courtesy STW) for the St Albans - Brighton run on 13th June. It will make life a lot easier if or when the fire gets clogged up and needs changing, so that we won't have to handle a hot ashpan back on to the engine. However, along the way some form of rake is useful for removing ash. I have previously used a little domestic rake, which was fine for 'Madeline' but did not reach to the back of the very long grate on the SRL. So I have made a bigger, heavier, rake out of stainless steel. The T bar is tapped M6 and the rod of the rake is threaded on the end, which is then centre punched in situ, to hold it. Finally the two components are silver soldered together.

The rake is quite long so as to clear the steering and some of the belly tank. There is a slow S bend in side profile which helps to get it over the lip at the entrance to the ashpan.

This should also be able to hook clinker out of the fire box door, if needed. I am also working on a water connection between the engine tender and a 75 litre tank in the waggon: more of that another day. The waggon is currently having its tyres vulcanised: I don't want them coming adrift on the 80 mile run!

Tim

The rake is quite long so as to clear the steering and some of the belly tank. There is a slow S bend in side profile which helps to get it over the lip at the entrance to the ashpan.

This should also be able to hook clinker out of the fire box door, if needed. I am also working on a water connection between the engine tender and a 75 litre tank in the waggon: more of that another day. The waggon is currently having its tyres vulcanised: I don't want them coming adrift on the 80 mile run!

Tim

Tim Watson- Number of posts : 585

Location : Herts

Registration date : 2008-07-02

Getting ready for the big run

Getting ready for the big run

The waggon has had new vulcanised tyres made for it by BH Leske: they won't come off!

I have fitted a rectangular 75l tank to the front of the waggon with an accessible tap just through the front boards. The connecting pipe is for a washing machine and threads under the seat and through the fair leads.

The pipe feeds through the manhole cover on the man stand via the entrance on the left. The pipe is a couple of inches high to accommodate the higher belly tank. It also has a washing machine stop cock on it to isolate the pipe from the waggon. The water supply is slow, but it will give cool water, rather than using the lifter to fill the tanks. My water indicator is visible, next to the feed and return pipes on the pump.

Not sure why this picture is at 90 degrees, but you get the idea.

Tim

I have fitted a rectangular 75l tank to the front of the waggon with an accessible tap just through the front boards. The connecting pipe is for a washing machine and threads under the seat and through the fair leads.

The pipe feeds through the manhole cover on the man stand via the entrance on the left. The pipe is a couple of inches high to accommodate the higher belly tank. It also has a washing machine stop cock on it to isolate the pipe from the waggon. The water supply is slow, but it will give cool water, rather than using the lifter to fill the tanks. My water indicator is visible, next to the feed and return pipes on the pump.

Not sure why this picture is at 90 degrees, but you get the idea.

Tim

Tim Watson- Number of posts : 585

Location : Herts

Registration date : 2008-07-02

Re: Frederick SRL(S)

Re: Frederick SRL(S)

Hi Tim

Good luck for tomorrow hope all goes according to plan ... Any idea what time you get into Brighton..

Andy

Good luck for tomorrow hope all goes according to plan ... Any idea what time you get into Brighton..

Andy

the coleman- Number of posts : 216

Age : 55

Location : worthing

Registration date : 2011-06-07

Re: Frederick SRL(S)

Re: Frederick SRL(S)

In theory, 2118.

Tim

Tim

Tim Watson- Number of posts : 585

Location : Herts

Registration date : 2008-07-02

Re: Frederick SRL(S)

Re: Frederick SRL(S)

In practice it'll be a minute later!!

Brilliant job on all the mods You've done Tim... I might get back to working on My engines soon & I'll be incorporating a few of Your ideas!!

Regards,

Tony

Brilliant job on all the mods You've done Tim... I might get back to working on My engines soon & I'll be incorporating a few of Your ideas!!

Regards,

Tony

Tony King- Number of posts : 856

Age : 69

Location : scotland

Registration date : 2008-10-31

Re: Frederick SRL(S)

Re: Frederick SRL(S)

Arrived Madeira Drive 0130

Tim

Tim

Tim Watson- Number of posts : 585

Location : Herts

Registration date : 2008-07-02

Re: Frederick SRL(S)

Re: Frederick SRL(S)

14 hours driving at 6mph average, my head is still spinning from watching the strobe light on the back of the trailer for 80 odd miles.

Mike

Mike

mikero- Number of posts : 261

Location : Brighton

Registration date : 2011-07-19

Re: Frederick SRL(S)

Re: Frederick SRL(S)

Congratulations and well done Tim and all your helpers what achievement

Andy.

Andy.

the coleman- Number of posts : 216

Age : 55

Location : worthing

Registration date : 2011-06-07

After the run

After the run

I have been given Frederick some TLC over the weekend. The pot hole we hit in Maida Vale was exceedingly vicious: below is the evolution of a busted steering chain. Both ends were sawn off the turnbuckle at the road side because the nuts had distorted into the threads. The results of this lousy road could have been very bad and would certainly have stopped our onward journey had I not carried spares.

Steve T and I are working on improvements to this aspect of the engine. I am certainly contemplating making the front springs active. I think the SRL probably has a harder ride that the RL because of the heavy front end weight.

Virtually every single nut and bolt in the back axles, perch bracket, chimney, and tender horn plates on the engine has needed taking up. I think that much of this came form the Maida Vale jolt. The chimney saddle casting became loose on the smokebox and will be refitted before the w/e, after the chimney has been repainted.

I thought that we had finished the journey at some speed on the last leg of the A23. On checking the speedometer this evening I see that our maximum was 17.2 mph!

So, like the Grand Fleet after the Battle of Jutland we have taken quite a lot of punishment but will be ready for the rally at Rutland Water next weekend.

Tim

Steve T and I are working on improvements to this aspect of the engine. I am certainly contemplating making the front springs active. I think the SRL probably has a harder ride that the RL because of the heavy front end weight.

Virtually every single nut and bolt in the back axles, perch bracket, chimney, and tender horn plates on the engine has needed taking up. I think that much of this came form the Maida Vale jolt. The chimney saddle casting became loose on the smokebox and will be refitted before the w/e, after the chimney has been repainted.

I thought that we had finished the journey at some speed on the last leg of the A23. On checking the speedometer this evening I see that our maximum was 17.2 mph!

So, like the Grand Fleet after the Battle of Jutland we have taken quite a lot of punishment but will be ready for the rally at Rutland Water next weekend.

Tim

Tim Watson- Number of posts : 585

Location : Herts

Registration date : 2008-07-02

Re: Frederick SRL(S)

Re: Frederick SRL(S)

Hello Tim,

I'm in the process of ordering up some "King of the Road" lamps for My Showman's engine & I'm fabricating brackets to hold them. I'm assuming yours are from Bruce at R A Barker engineering, if so, could you give Me dimensions for the "post size" they sit on, so I can continue fabrication of brackets... It'll probably be a while before Bruce produces the next batch of lights & it'd be nice if I can have the brackets all ready for the great day when they arrive!!!!

Regards,

Tony

PS. Glad "Fredrick" all ready for action again, well done!!... As always very interested in Yours & Steve Trails mods to engines!!

I'm in the process of ordering up some "King of the Road" lamps for My Showman's engine & I'm fabricating brackets to hold them. I'm assuming yours are from Bruce at R A Barker engineering, if so, could you give Me dimensions for the "post size" they sit on, so I can continue fabrication of brackets... It'll probably be a while before Bruce produces the next batch of lights & it'd be nice if I can have the brackets all ready for the great day when they arrive!!!!

Regards,

Tony

PS. Glad "Fredrick" all ready for action again, well done!!... As always very interested in Yours & Steve Trails mods to engines!!

Tony King- Number of posts : 856

Age : 69

Location : scotland

Registration date : 2008-10-31

Oilers re-visited

Oilers re-visited

One of the Burrell-style big end oiler tops that I had made for Frederick was lost, just north of Brighton on the A23. We were doing 17.2mph on the last leg our St Albans to Brighton run (incidentally this will shortly have raised well over £4000 for Parkinson's UK).

For the subsequent rally at Rutland Water, I simply refitted both big ends with the standard STW issue cap, albeit with the hole slightly increased in size to take my narrow-nozzle Reilang oil can tip. I was amazed at how dirty the engine became with oil splashes! Hence, I have now re-made the missing cap and photographed the components (I didn't do this last time).

General view of components (underside). The lid (left) is a turned from brass with a 4BA thread on the pin sticking out from the lid. The body of the cap (centre) is modified from the standard top by facing it off and drilling two more holes on the same radius and diametrically opposite, one for the oil to go in and the other for a location stud (hole not visible in this view). The nut and spring can also be seen, the latter sourced from a ball point pen.

General view of components (top). The cap body (left) can be seen with he oil hole at the bottom, and the original centre hole used as the pivot for the cap. The oil hole has to be partially drilled from the top and then the hole drifted centrally with a dental bur to avoid the screw thread on the outside of the cap. The brass stud that locates the cap can be seen at the top of the image and is silver soldered in place. The lid (centre) has a lip on it to enable a finger tip to engage it to be able to rotate it on the body.

Assembled oiler cap viewed from the underside. A little bit of Loctite thread-lock retains the nut in place, with the sprig tensioning the lid to the cap. It cannot extend much past the depth of the cap screw threads or else it will interfere with the oil feed pipe and wick in the reservoir.

Oiler cap in place with the lid closed and held by the stud engaging in the oil hole, to stop rotation of the cap.

Cap rotated and oil can spout in place injecting oil into the oiler reservoir.

PS. Sorry Tony, forgot to measure the lamp brackets. Will do this ASAP. I have recently been making brackets and fixings for the waggon components to be stored in my BV85 box trailer. This has much improved things and will make transporting all the bits so much easier. It was essential to improve storage in the trailer (especially the 75l tank) as I am about to go to the Boconnoc Rally and also the WESES Engine Hill road run and Stithians Rally in August.

Tim

For the subsequent rally at Rutland Water, I simply refitted both big ends with the standard STW issue cap, albeit with the hole slightly increased in size to take my narrow-nozzle Reilang oil can tip. I was amazed at how dirty the engine became with oil splashes! Hence, I have now re-made the missing cap and photographed the components (I didn't do this last time).

General view of components (underside). The lid (left) is a turned from brass with a 4BA thread on the pin sticking out from the lid. The body of the cap (centre) is modified from the standard top by facing it off and drilling two more holes on the same radius and diametrically opposite, one for the oil to go in and the other for a location stud (hole not visible in this view). The nut and spring can also be seen, the latter sourced from a ball point pen.

General view of components (top). The cap body (left) can be seen with he oil hole at the bottom, and the original centre hole used as the pivot for the cap. The oil hole has to be partially drilled from the top and then the hole drifted centrally with a dental bur to avoid the screw thread on the outside of the cap. The brass stud that locates the cap can be seen at the top of the image and is silver soldered in place. The lid (centre) has a lip on it to enable a finger tip to engage it to be able to rotate it on the body.

Assembled oiler cap viewed from the underside. A little bit of Loctite thread-lock retains the nut in place, with the sprig tensioning the lid to the cap. It cannot extend much past the depth of the cap screw threads or else it will interfere with the oil feed pipe and wick in the reservoir.

Oiler cap in place with the lid closed and held by the stud engaging in the oil hole, to stop rotation of the cap.

Cap rotated and oil can spout in place injecting oil into the oiler reservoir.

PS. Sorry Tony, forgot to measure the lamp brackets. Will do this ASAP. I have recently been making brackets and fixings for the waggon components to be stored in my BV85 box trailer. This has much improved things and will make transporting all the bits so much easier. It was essential to improve storage in the trailer (especially the 75l tank) as I am about to go to the Boconnoc Rally and also the WESES Engine Hill road run and Stithians Rally in August.

Tim

Tim Watson- Number of posts : 585

Location : Herts

Registration date : 2008-07-02

Re: Frederick SRL(S)

Re: Frederick SRL(S)

Hi Tim,

am thinking of replicating your oilers - now I am in steam I can see just how much oil the others fling out. I can follow most of how it is made. How though have you made the tab that sticks out to ease turning it around?

With best wishes

Simon

am thinking of replicating your oilers - now I am in steam I can see just how much oil the others fling out. I can follow most of how it is made. How though have you made the tab that sticks out to ease turning it around?

With best wishes

Simon

MrStationHouse- Number of posts : 314

Location : Malmesbury

Registration date : 2011-04-26

Frederick 2016

Frederick 2016

For a variety of reasons I have not attended quite so many rallies this year. Over the winter Frederick had a bit of a tidy up and re-guilding where it had worn a bit: Frederick is not a wall flower. Now looks nice and smart again. The engine had a small tap from the water pump drive where it was slapping sideways. The pin that locates it laterally (the oiler attaches to it) had worn and so this was turned down and a new collar soft soldered to it to take up the slack. All now nice and quiet.

Our first outing was at Fawley Hill, in mid May, where Frederick was lined up for a photograph next to William V.

Whilst generating on the Friday night I had a problem with a loose connection on the distribution board which arced and burnt out! This was rapidly replaced for our Herts Steam Club rally at Oaklands College in early June. I also took the opportunity to make the board smaller at the same time (haven't yet photographed it)

We had a super rally at St Albans and Mike had Tommy running really well. We had my wagon behind supplying water as the Foden is a bit thirsty.

My grandson, Charlie, loves going in Mike's Foden.

This video was taken at our HSEPS rally, with Bruce Harvey driving Frederick and the Young Watson family as passengers.

https://youtu.be/lYLx0kkf86M

Finally, I shall be taking this new toy, called "Thumper" to a show at Blenheim Palace on Sunday 3rd July.

Assuming the weather is decent, I will be roading Frederick to Redbourn Museum on the 10th and the following w/e 16-17th July is the NTET SAC do at Oaklands College. If anyone would like to bring a miniature to this please let me know.

Tim

Our first outing was at Fawley Hill, in mid May, where Frederick was lined up for a photograph next to William V.

Whilst generating on the Friday night I had a problem with a loose connection on the distribution board which arced and burnt out! This was rapidly replaced for our Herts Steam Club rally at Oaklands College in early June. I also took the opportunity to make the board smaller at the same time (haven't yet photographed it)

We had a super rally at St Albans and Mike had Tommy running really well. We had my wagon behind supplying water as the Foden is a bit thirsty.

My grandson, Charlie, loves going in Mike's Foden.

This video was taken at our HSEPS rally, with Bruce Harvey driving Frederick and the Young Watson family as passengers.

https://youtu.be/lYLx0kkf86M

Finally, I shall be taking this new toy, called "Thumper" to a show at Blenheim Palace on Sunday 3rd July.

Assuming the weather is decent, I will be roading Frederick to Redbourn Museum on the 10th and the following w/e 16-17th July is the NTET SAC do at Oaklands College. If anyone would like to bring a miniature to this please let me know.

Tim

Tim Watson- Number of posts : 585

Location : Herts

Registration date : 2008-07-02

Page 10 of 12 •  1, 2, 3 ... 9, 10, 11, 12

1, 2, 3 ... 9, 10, 11, 12

Similar topics

Similar topics» Weight of engine

» Tim's Showman Frederick on YouTube

» Frederick road running over London’s Bridges for Parkinson’s

» Tim's Showman Frederick on YouTube

» Frederick road running over London’s Bridges for Parkinson’s

Page 10 of 12

Permissions in this forum:

You cannot reply to topics in this forum|

|

|