Rear wheels made in Duesseldorf

Page 1 of 1

Rear wheels made in Duesseldorf

Rear wheels made in Duesseldorf

Putting together all parts of the rear wheels took me quite some time, but I had no problems with that. I always read the instructions very carefully. But now I have to make a confession: In the instructions it is strongly recommended to "araldite" the gaps between the spokes, the hubs and the rims. I did not do anything like that. It is a tremendous lot of work, only to make sure, that the spokes do not become loose, when you move your finished Burrel over long distances on hard ground. But I am not planning this. When my machine is finished completely, I will heat and steam it up and will test all functions, I just want to know, everything works. After that my Burrel will serve as a show-piece in our entrance hall.

I had already told you, that I had made a grievious decision by ordering the wheel without rubber tyres, I wanted to make an agricultural steam traction engine with strakes on the rear wheels for better grip on soft ground. This meant a lot of additional work for me:

[/list]

The whole procedure took me more than two months. If I had realized in advance, how much labour it would mean, I would probably have ordered the wheels with rubber tyres. But now I am happy with it.

I had already told you, that I had made a grievious decision by ordering the wheel without rubber tyres, I wanted to make an agricultural steam traction engine with strakes on the rear wheels for better grip on soft ground. This meant a lot of additional work for me:

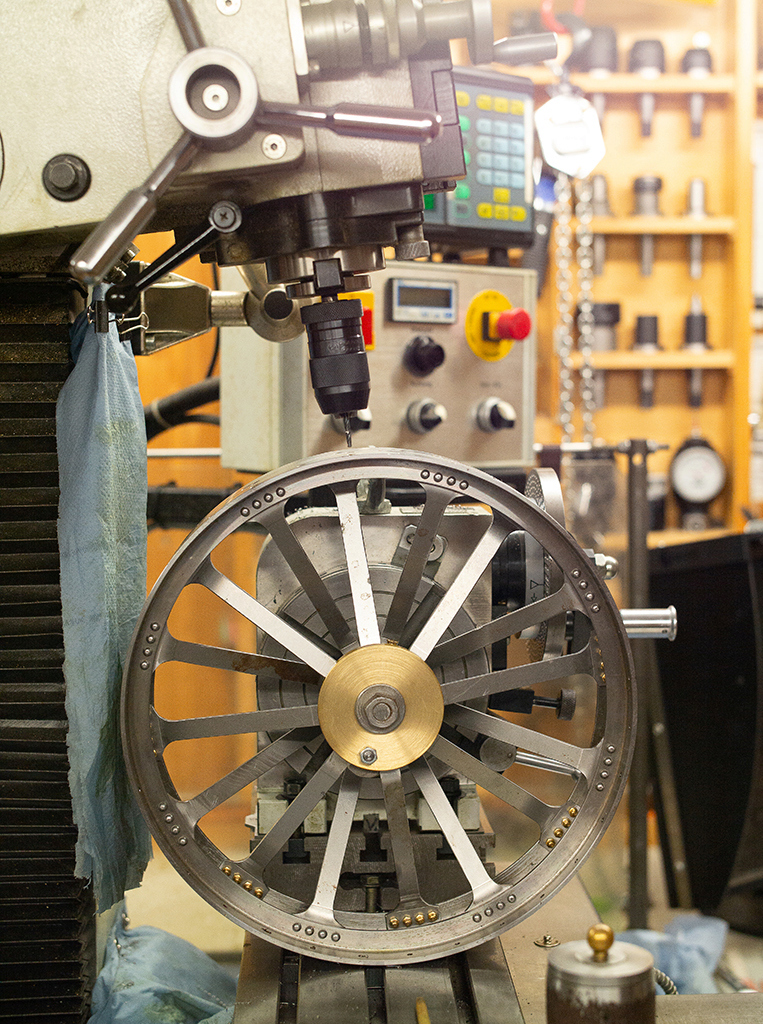

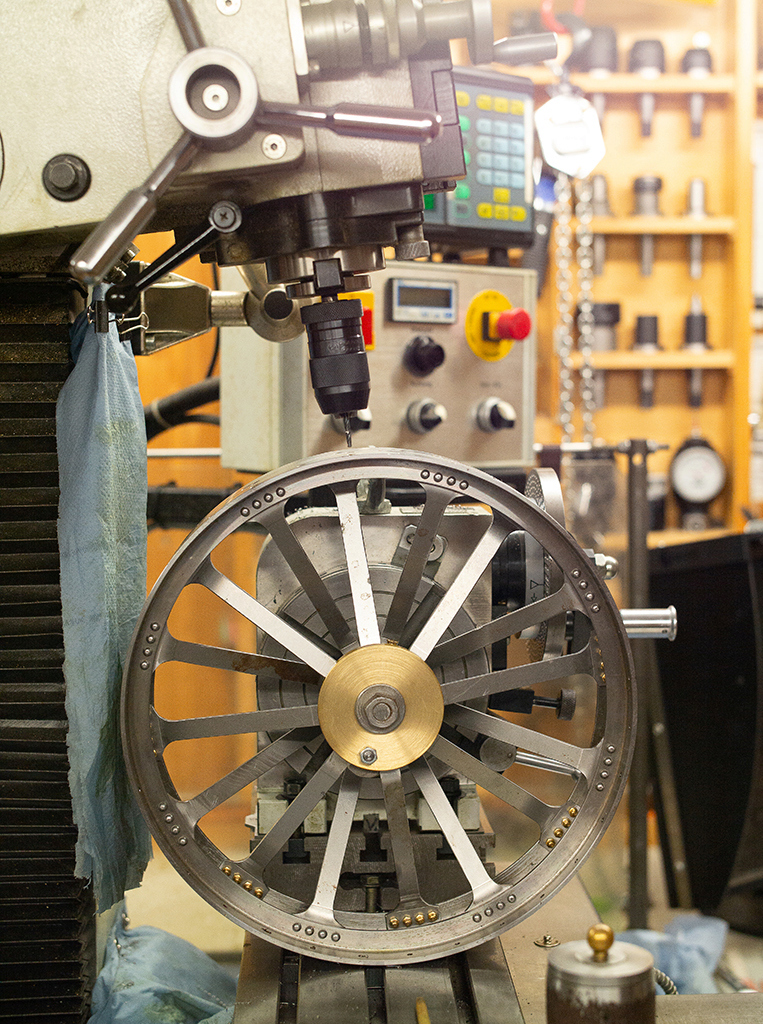

- I had to drill threaded holes into the wheel rims. My milling-machine was a little bit too small for this operation, but with some tricks I could manage it.

- Making the strakes:

32 pcs for the left wheel, 32 pcs for the right wheel. I used steel strip 20 x 2 mm

The strakes did not align with the wheel rims well enough. So I had to make a special forming tool to adjust them

- In the next photo you see the riveting procedure:

[/list]

- I have put rivets at the two sides of the rim. The inner holes got countersunk socket screws, which I removed after setting of the rivets and filled the holes with 2K-copper-repair-paste.

- For the final finish I used a band grinder.

The whole procedure took me more than two months. If I had realized in advance, how much labour it would mean, I would probably have ordered the wheels with rubber tyres. But now I am happy with it.

Last edited by karl heinz marschner on Wed 14 Sep 2022, 7:04 pm; edited 5 times in total (Reason for editing : Spelling error)

karl heinz marschner- Number of posts : 33

Location : Duesseldorf, Germany

Registration date : 2021-04-13

Similar topics

Similar topics» rear wheels

» Design so far

» Tone's Showmans second lot!

» Lynn Robinson. Showman Scenic

» Foden Rear Wheels

» Design so far

» Tone's Showmans second lot!

» Lynn Robinson. Showman Scenic

» Foden Rear Wheels

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum|

|

|